Date: 13 October 2020

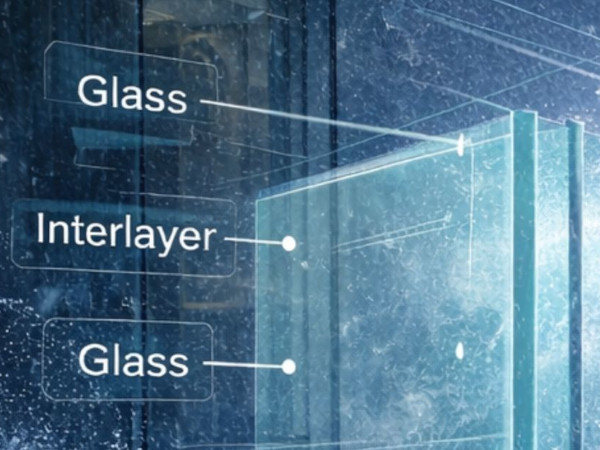

However, the use of this material has generated fears and doubts due to the fragility of glass which obviously carries the idea of danger. It is well known an accidental human impact with glass panes is possible and can be a source of injury.

Researches in combination to modern production techniques grant good mechanical properties to glass, thus satisfying the requirements for safety in building as well as in other applications.

For this reason, it has been necessary to define the parameters of the safety glass and the ways to test and validate it. One of the testing methods is the pendulum, in short it consists in launching a semi-rigid object against the panel of glass simulating in this way a human body impact.

The European standard EN12600 has specified a pendulum impact test method for single flat panes of glass for use in building and glaziers, which are becoming more and more conscious of the importance of supplying safety glass at various levels.

As a qualified manufacturer of laminating machines and laminating interlayer lamination, RCN SOLUTIONS has been asked to manufacture a pendulum tester to apply to the standard, and the company has accepted and developed REVA BF, allowing customers to verify in-house the compliance of the use of this product and work in total confidence.

The Standard EN12600 defines not just how to perform the tests, but also the parameters for construction of the pendulum tester.

One of our testers is ready to be delivered in Portugal, where the standard also allows end product certification on the basis of the pendulum test performed in-house.

In other countries, test within the factory are not accepted, but they can be important guideline prior to submitting specimens to the institutes charged with certification, preventing unnecessary expenses in case of the test fails.

Although it is not intent to serve as a substitute for professional test laboratories, RCN has decided, to process this construction only as a part of customer service, aiming to support their customers in their way in search for safe end product.

RCN SOLUTIONS thinks this proposal could meet the approval of the market and could offer better support for their customers.

600450

600450

Add new comment