13 Beaufort Square

London NW9 4FJ

United Kingdom

LUARI

As glass production processes have advanced, the demand for accurate, automated inspection has increased significantly. Many traditional inspection methods remain dependent on manual operation and subjective judgement, leading to variability in results. LUARI was established to support the transition toward objective, instrument-based measurement by providing access to advanced optical inspection technologies engineered specifically for industrial use.

Products

Product Overview

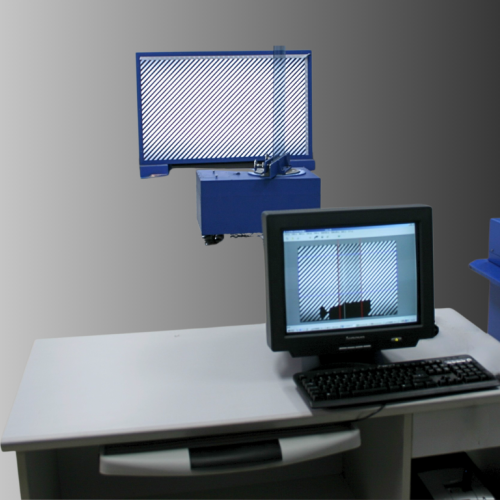

The FZT-2 Fully Automatic Zebra Angle Measurement System is designed for accurate evaluation of optical distortion in float glass. By utilizing controlled zebra pattern projection together with automated analysis, the system delivers reliable and repeatable measurement results to support modern quality assurance processes.

Suitable for laboratory and production quality-control environments, the FZT-2 enables manufacturers to maintain consistent optical performance while significantly reducing operator subjectivity.

Key Features

• Fully automatic zebra angle measurement

• High repeatability for objective quality assessment

• Stable optical system for precise distortion evaluation

• Automated data processing for improved efficiency

• User-friendly operation

• Designed for continuous laboratory use

• Minimizes human error in visual inspection

Applications

• Float glass manufacturing plants

• Quality control laboratories

• Architectural glass evaluation

• Automotive glass optical testing

• Research and development centers

Compliance and Testing Principles

The system follows internationally recognized optical inspection methodologies and supports testing practices aligned with standards such as ASTM C1036 for flat glass quality evaluation.

Operational Value

Implementing automated zebra angle measurement strengthens process consistency, improves inspection reliability, and supports manufacturers in delivering high-quality glass products that meet demanding industry requirements.

For technical specifications or configuration guidance, please contact our engineering team.

Product Overview

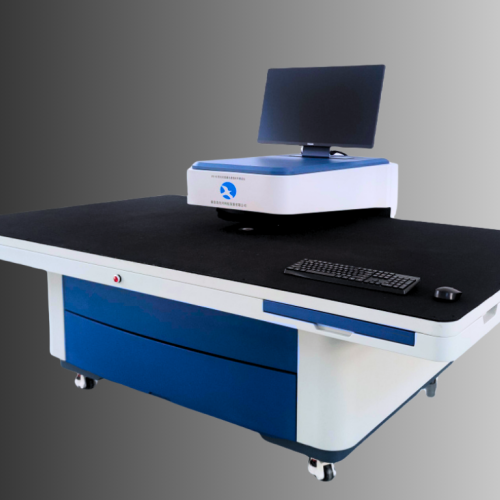

The BTG-8 High-Precision Glass Thickness Measurement System is engineered for accurate and consistent thickness evaluation in flat glass applications. Combining advanced sensing technology with a stable mechanical structure, the system delivers dependable measurement results suitable for both laboratory verification and production quality control.

By enabling precise dimensional monitoring, the BTG-8 supports manufacturers in maintaining strict tolerances, improving process stability, and ensuring consistent product quality.

Key Features

• High-precision thickness measurement

• Excellent repeatability for reliable data comparison

• Robust mechanical design for long-term stability

• Efficient measurement workflow

• User-friendly operation

• Suitable for continuous industrial use

• Minimizes operator influence on results

Applications

• Float glass manufacturing plants

• Architectural glass production

• Automotive glass facilities

• Quality control laboratories

• Research and development centers

Engineering Value

Accurate thickness control plays a critical role in downstream processing, product performance, and compliance with customer specifications. The BTG-8 enables manufacturers to strengthen quality assurance procedures while supporting efficient and stable production operations.

System Design Philosophy

The system is developed with a focus on measurement reliability, operational simplicity, and long service life — making it a dependable solution for modern glass producers.

For technical specifications or configuration guidance, please contact our engineering team.

Product Overview

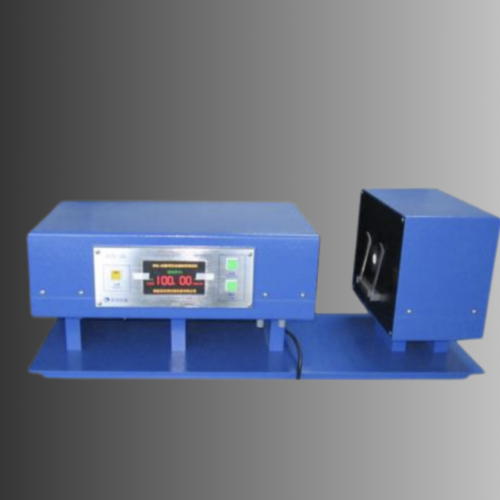

The BTR-1S Optical Transmission, Reflectance and Haze Measurement System is developed for quantitative evaluation of visible light properties in glass. Utilizing an integrating sphere measurement principle, the system delivers accurate and repeatable results to support laboratory analysis and production quality control.

Designed for modern testing environments, the BTR-1S enables manufacturers to verify optical performance, optimize product characteristics, and maintain consistent quality standards.

Key Features

• Measurement of visible light transmittance

• Reflectance evaluation

• Accurate haze measurement

• High repeatability for reliable data comparison

• Integrating sphere technology for precise optical capture

• Supports both D65 and A illuminant measurement modes

• User-friendly operation with efficient workflow

• Suitable for laboratory and industrial environments

Applications

• Architectural glass testing

• Float glass manufacturing

• Coated glass evaluation

• Laminated and insulating glass analysis

• Automotive glass testing

• Research and development laboratories

Engineering Value

Accurate measurement of light transmission and haze is critical for energy performance, visual comfort, and regulatory compliance in modern glazing systems. The BTR-1S provides dependable data that helps manufacturers strengthen quality assurance and meet demanding project specifications.

System Design Philosophy

Engineered with a focus on measurement stability, operational simplicity, and long service life, the BTR-1S is a reliable solution for glass producers seeking consistent optical evaluation.

For technical specifications or configuration guidance, please contact our engineering team.