Glass Pre-processing Technology

News

Zero worries. Maximum productivity.

Chongzheng Shengda Glass opts for the first 8 × 3.3 metre TPA line from LiSEC.

CMS aura is the vertical dry seaming machine designed for those seeking efficiency, simplicity, and savings in the glass processing workflow.

HEGLA-HANIC redefines how glass companies manage orders with an industry-specific Microsoft Copilot assistant.

A smart solution for lighter, slimmer, and more efficient insulated glass units.

The SplitFin is a vertical processing line for flat glass with two processing towers: EPS-B for edge processing and MRX-B for internal processing.

Discover how automated TPA application ensures accuracy, speed and reliable processing – even in large-format production.

On 6 and 7 November, LiSEC welcomed more than 60 customers from Central and Eastern Europe and the Commonwealth of Independent States (CIS) region to Seitenstetten.

LiSEC is meeting challenges and emerging trends with innovative concepts and custom solutions.

New model FG for fast grinding and simultaneous edge seaming.

Scm Group wins the SMAU Innovation Award for “Smart Spindle” — an AI-powered system that predicts faults, cuts downtime, and boosts efficiency.

In construction, automotive and interior design, there are multiple applications and often they require solutions that are both lightweight and durable, with flawless finishing.

HEGLA will showcase its latest Thin Glass Cutting System, Galactic-TG, at Booth #16048 during GlassBuild America.

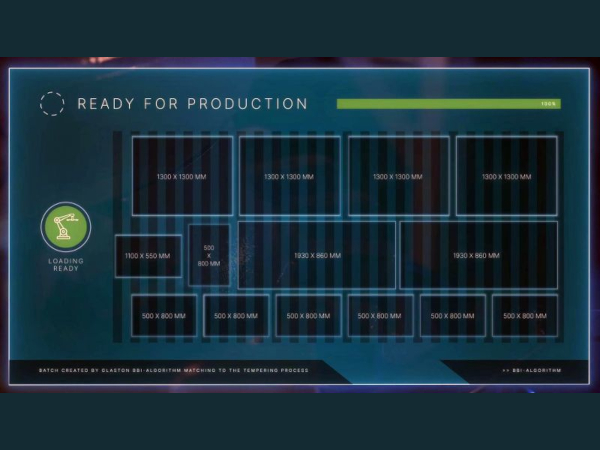

At GlassBuild America 2025, Glaston showcases its latest innovations in glass processing, emphasizing smart automation, energy efficiency, and production flexibility.

In automotive glazing, safety is never optional – but neither is durability. Windshields must withstand stone impacts, resist scratches and meet all regulatory safety standards.

LiSEC has been named ‘Austria's Best Managed Company 2025’. This competition was organised by Deloitte Austria, Raiffeisen Landesbank Niederösterreich-Wien and the business magazine trend.

Articles

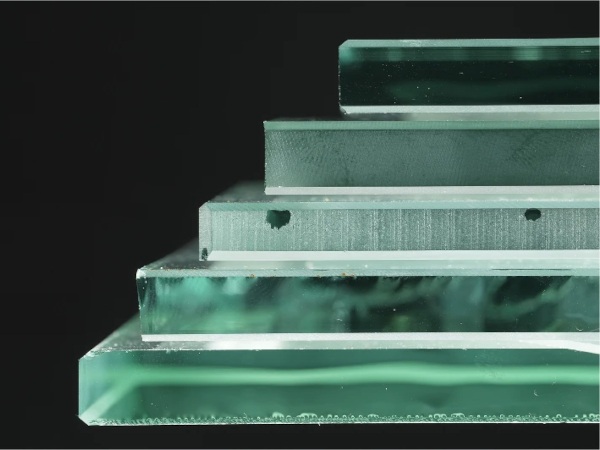

This study explores how fibre optic sensors can accurately measure strain and temperature in laminated glass systems, revealing how adhesives, temperature, and load conditions influence the mechanical behaviour of PVB and embedded sensors.

Laser technology is rapidly reshaping the future of glass processing, offering a level of precision and innovation that traditional methods can’t match.

In this fourth episode, the focus is on how to clean glass plates efficiently.

In this eighth episode, we delve into optimizing energy efficiency in Low-E production.

Digital printing is transforming the glass industry, offering faster production, smaller batches, and more creative freedom—while reshaping processes and sustainability requirements.

This paper presents a groundbreaking technological development in the optical quality of tempered glass.

This study explores the strength and fracture behavior of waterjet-cut glass, comparing it to traditionally cut glass through detailed testing and analysis.

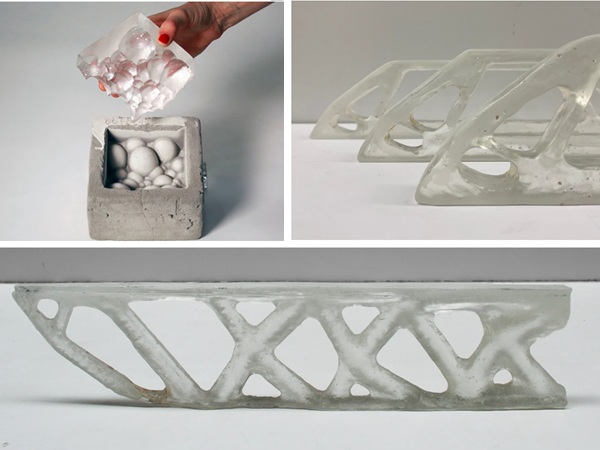

Glass casting displays great forming potential allowing for the realisation of three-dimensional glass elements of virtually any shape and size, as showcased in glass art.

The latest Glastory blog explores the evolving role of automation in glass processing, highlighting examples of how it is transforming efficiency in the industry.

What glass processes gain the most from automation? In this blog, we’ll focus on some of the particularly promising application areas.

When finding, training and retaining personnel for routine jobs is a challenge, processing automation offers a game-changing solution.

COMPANIES

Beijing GreatDia Superhard Tools Co.,Ltd

No 5, Fu rong jie jia, Xi ma ge Zhuang village, Gao li ying town

Shun yi district

Shunyi Qu

Beijing Shi, 101300

China

Hornos Industriales Pujol

Carrer del Pla, 108-110, Pol. Ind. El Pla

08980 Sant Feliu de Llobregat Barcelona

Spain

Luoyang North Glass Technology Co., Ltd.,

No. 20 Binhe Road, High-tech Development Zone,

Luolong Qu

Luoyang Shi

Henan Sheng, 471003

China