Via per Monastier, 4

Vallio di Roncade 31056 TV

Italy

FOREL

Forel, established in 1976, is an Italian company of solutions for flat glass and double-glazing processing (vertical cutting, sorting systems, edge processing line, laminating glass lines and IG line).

Forel, which employees over 280 people, has its headquarters and production plants in Italy, but the company owns commercial branches and offices in USA, Canada, United Kingdom, South Africa, Russia and cooperates with 25 local agencies in the world.

The sales network is worldwide present and has developed sales relations with over 70 countries, exporting the technological tradition and dynamism of Italian engineering.

Forel core philosophy is innovation: every year, a remarkable part of the incomes are invested in R&D.

THE 10 VALUES OF MADE IN FOREL

FOREL S.p.A. is a company intent on constantly upgrading all its business activities. This continuous-growth objective is pursued in accordance with a series of values, identifiable in a way of being, in a way of behaviour and in the way business relations are carried on. The achievement of these values enables us to find the favour of our stakeholders, who thus benefit from our passion for the flat glass working world and from our positive attitude towards the global management of business projects.

1. Our company is orientated towards satisfying customer requests

2. We develop automations and technologies for flat glass processing

3. We pursue quality excellence

4. Our priority goal is innovation

5. Changes always represent positive opportunities

6. Our company is successful thanks to the people who work with us

7. We are committed to creating a safe and comfortable work environment

8. We are actively involved in Sustainable Development

9. We communicate in an open and transparent way

10. We support the tradition of a family firm open to the global market

Products

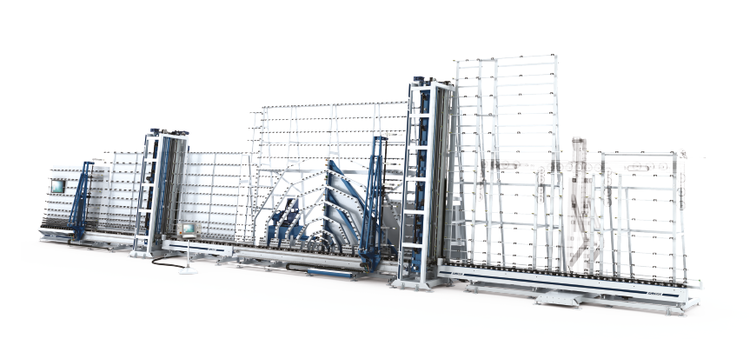

AUTOMATIC STOCK SELECTOR

VERTICAL AUTOMATIC LOADER

VERTICAL CUTTING LINE

TILTING TABLE

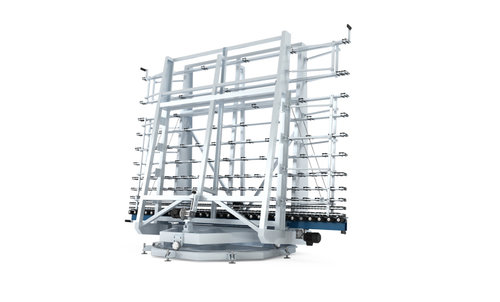

ART. SS

SORTING SYSTEM

★ HIGHLY CONFIGURABLE MACHINE ★ INNOVATIVE SOFTWARE ★ HIGH QUALITY STANDARDS

DESCRIPTION

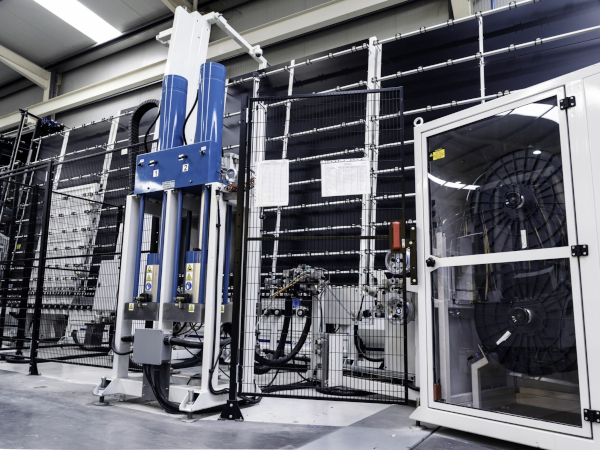

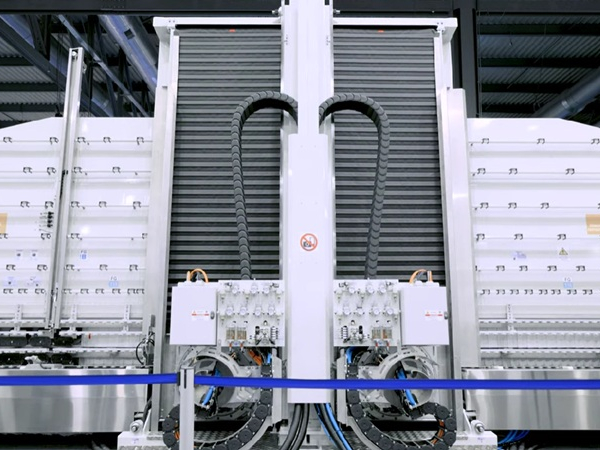

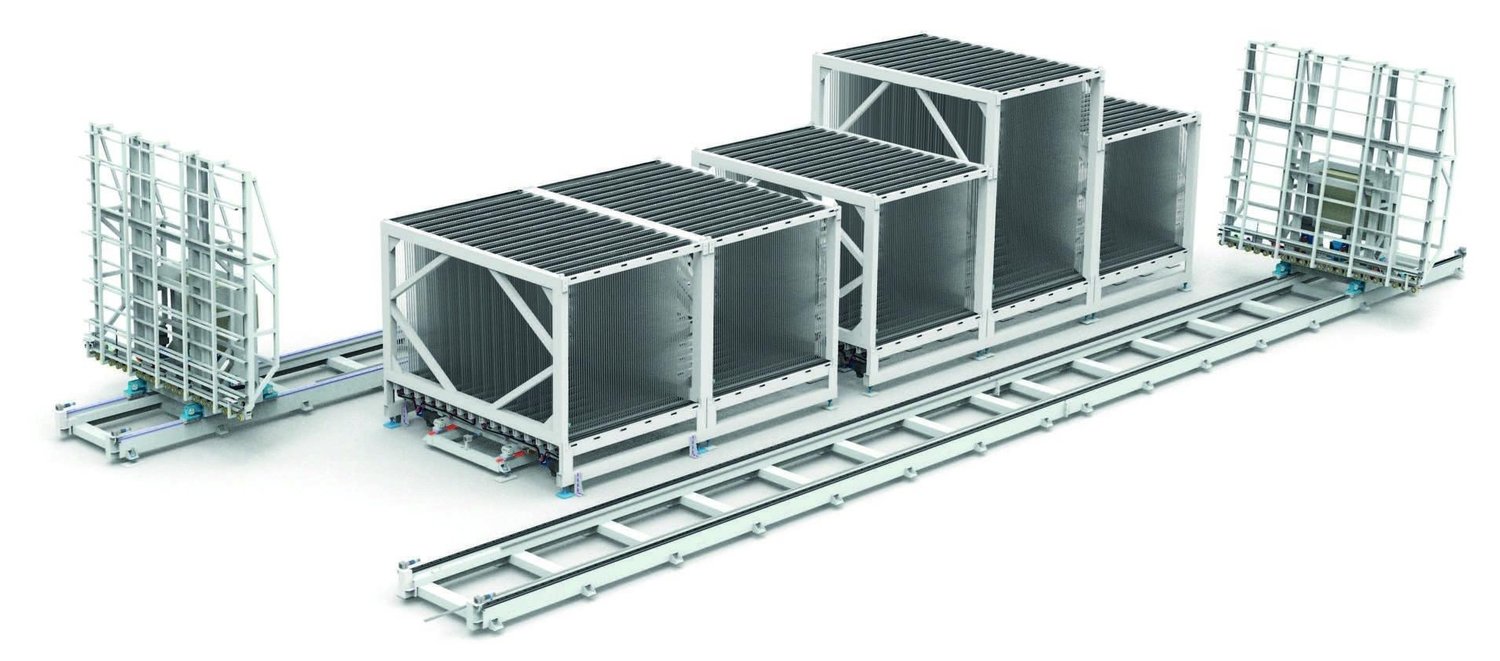

Art.SS is a complete solution for the optimization of the production through an automatic process of handling and storing within the glasswork. This system fits between the cutting lines and other production process. It is a highly configurable machine with modules for handling and storing to better satisfy the production requirements of the glasswork and to ensure a high deposit capacity. The system is interfaced with an arrissing (optional), plus a cleaning and quality control upstream which ensures the precise traceability of each piece and the certainty of store to stock material free from defects. An innovative software allows a real-time view on the state of orders. The SS is highly modular and the configuration can be adapted to existing production processes either of Forel trademark or other manufacturers. Due to glass handling being all automatic, the operator’s manual work is reduced to a minimum which means a drastic reduction of risks and greater safety in the work environment.

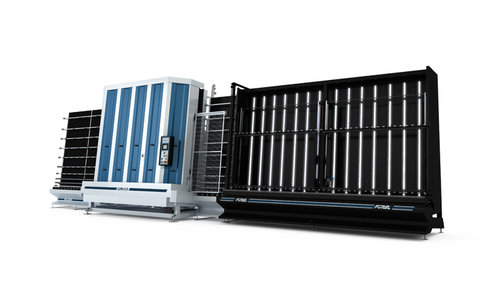

ART. LL

LAMINATING LINE

★ OPTIMISED FOR SPECIAL GLASS ★ DEVELOPED WITH LEADING GLASSWORKS ★ HIGH QUALITY STANDARDS

DESCRIPTION

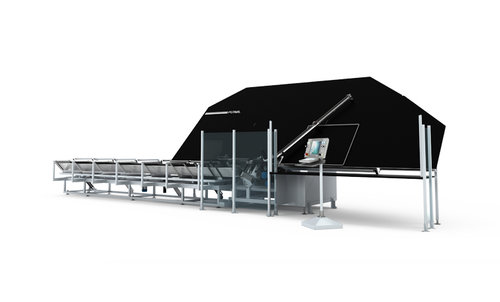

The LL2645 line has been designed and engineered specifically for laminating tempered glass (and other glass) with custom sizes, shapes and types for a mixed production. The line complies with all current CE regulations in safety and uses dedicated programming software to control and synchronise all stages in production thereby optimising work times and energy consumption, according to the different glass pane dimensions. A combination of cutting edge technology and the best in automation currently available for the production of premium quality laminated glass. Every unit in the line is designed and built in Italy using the most modern technology and the know-how that only the Forel experience can guarantee. Years of in-depth research and continuous development have made it possible to create machinery for all and every requirement in safety glass. All this has contributed towards advancing “made in Italy” and “made in Forel” throughout the world. Tempered, low emissivity, acid etched, screen printed and any other type of glass with special treatments can be processed with remarkable simplicity by the Forel plant.

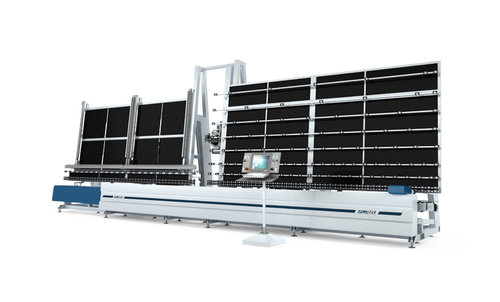

Our heritage of technologies to reach the highest performing IGUs

AUTOMATIC COATING REMOVER

VERTICAL WASHING MACHINE

SHAPE RECOGNITION SCANNER

QUALITY CONTROL SCANNER

AUTOMATIC FLEXIBLE SPACER APPLICATOR

AUTOMATIC FLEXIBLE SPACER APPLICATOR

AUTOMATIC ROTATING CONVEYOR

ROTATING CORNER CONVEYOR

COUPLING FLAT PRESS UNIT

COUPLING FLAT PRESS WITH GAS FILLING

AUTOMATIC GAS FILLING CONVEYOR

MANUAL FOUR STATION GAS FILLER

AUTOMATIC CORK PADS APPLICATOR

AUTOMATIC VERTICAL SEALING ROBOT

HOT MELT AUTOMATIC SEALING ROBOT

SEALING ROBOT HIGH PERFORMANCE

PUMPING UNIT FOR SEALANT

Art. 1T120B/M - 1P120B/M - 1S120B/M

TWO COMPONENT EXTRUDER SEALANT

AUTOMATIC PROFILE BENDER

MANUAL BUTYL EXTRUDER