Date: 17 July 2025

From September 16 to 19, 2025, Forel will once again take center stage at Vitrum, the international trade show dedicated to glass processing technologies and techniques, held at Fiera Milano Rho. Visitors will find Forel at Hall 11 – Booth M01 S14, where the company will showcase the very best in machine automation for both the industrial and residential glass sector, along with its latest innovations, developed under the “Made in Forel” philosophy.

Vitrum is a fantastic opportunity to meet with customers, professionals, and partners from around the world, to share ideas and present the latest development achievements for the future. “Every trade show is a valuable moment to exchange and inspire” says Riccardo Vianello, CEO and Vice President of Forel. “But Vitrum holds special meaning for us: we’re on home turf, in front of an international and knowledgeable audience, and we want to send a clear message—Forel continues to strive and invest in tangible solutions that make a real difference to our customers.”

Insulating glass: Continuous innovation, beyond 20mm

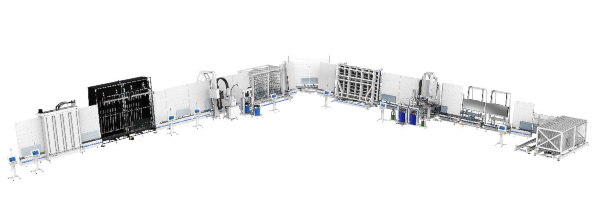

One of the highlights at the Forel booth will be its High-Tech insulating glass line, now enhanced with another innovation for thermoplastic spacer. Demonstrated live will be the newly patented extrusion technology for spacers over 20mm wide—a breakthrough that sparked significant interest (and a surge in orders) during Glasstec 2024 in Düsseldorf.

Thanks to the inline production buffer with an integrated straightening station, Forel has made it possible to process thermoplastic spacers over 20mm in width adding in enhanced stability and precision. This technological technique allows the thermoplastic spacer to cool and stabilize before pressing, preventing deformation, ensuring spacer alignment and guaranteeing consistent quality. The internationally patented system also supports efficient processing of thin spacers (down to 5.3 mm in height), reducing material use and improving both thermal and acoustic performance.

This integrated evolution of a dynamic control system demonstrates Forel’s ability to turn R&D design into cutting-edge results delivering a realistic industrial solution.

Forel will also feature a major new development in system diagnostics: an intelligent tool designed to simplify the detection and resolution of electrical alarms. It provides added support to operators, reducing downtime and improving plant management.

Vertical edge processing: Harmonised speed and precision

Another key feature of our display will be the latest advancements in vertical edge processing as Vitrum 2025 serves as center stage for the unveiling of a revolutionary new machine.

Designed for high-speed operation this platform can easily be integrated into automated glass productions, insulating glass lines or simply standalone as part of a glass processing solution.

Positioned at the head of the insulating glass line, this next-generation machine has been developed to optimize workflow, reduce cycle times, and increase overall process efficiency. Capable of ultra-fast arrissing (seaming) and rough edge grinding, it matches the pace of traditional machines while eliminating bottlenecks in insulating glass production.

These updates are all part of a broader company vision: All Forel machines are designed to be part of a fully integrated system, where operator safety and efficiency are paramount.

Sorting System: At the forefront of Connected Logistics

Vitrum will also provide an opportunity to explore one of Forel’s most talked-about technologies: the Sorting System for finished glass units. This solution automates downstream logistics for insulating glass panels, enabling automatic postproduction unloading, sorting and storage with no manual intervention.

The system includes patented supports that vertically transports just completed sealed units to be safely stored during the curing phase. This eliminates the risk of pane distortion and streamlines production management, optimizing the entire workflow process. The Sorting System is a vital step forward towards full automation, freeing up resources while improving overall plant performance and efficiency.

Ongoing innovation and global vision

Behind these High-Tech solutions lies Forel’s clear commitment to future-focused growth. In the past year alone, the company filed eight new patents, expanded its headquarters with over 8,000 square meters of new production space, and opened its new Forel North Europe branch in Mönchengladbach (Germany), reinforcing the strategy of being geographically closer to customers and markets. 2025 is shaping up to be a pivotal year, with several new initiatives underway to strengthen Forel’s dedication to innovation and sustainable growth.

Vitrum 2025 is a signature event and marks a milestone at Forel as it endorses its role as a leading innovator within flat glass processing—showcasing real solutions that are already transforming glass plants from around the world. As always, the Forel team will be on hand for live demonstrations, technical discussions, and customised consultations.

Want to learn more about Forel’s solutions for your glass plant? Join us in Milan, September 16–19, Hall 11 – Booth M01 S14.

600450

600450

Add new comment