Insulating Glass Technology

News

TSS is not just technical support – it is a forward-looking partner for realising high performance production solutions.

Sparklike, a global leader in non-destructive gas measurement solutions for insulating glass units (IGUs), announced the appointment of Sasu Koivumäki to its Board of Directors.

This year marks the 10th anniversary of Sparklike Laser Portable™, a major milestone in the development of non-destructive gas measurement for insulating glass units.

Chongzheng Shengda Glass opts for the first 8 × 3.3 metre TPA line from LiSEC.

Xinruineng ensures compliance with China’s 85% argon requirement by using Sparklike’s non-destructive gas measurement technology to guarantee reliable energy performance in insulating glass units.

Saint-Gobain Glass UK is launching PLANITHERM® NEO, an advanced thermal insulation glass, designed to meet the evolving performance, aesthetic and sustainability requirements of the UK window and door market.

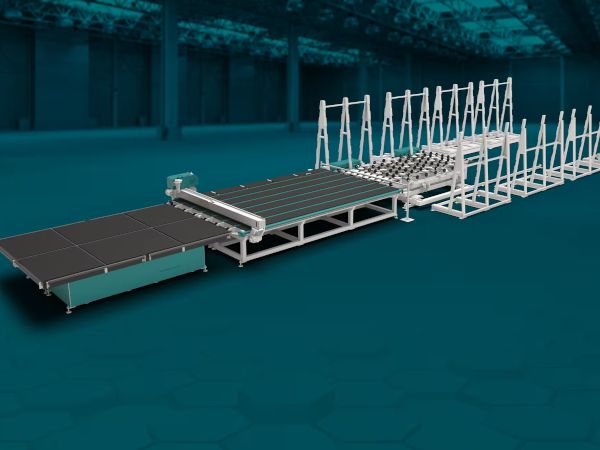

The LiTROS glass cutting line is a sophisticated, modular solution for industrial processing of float glass.

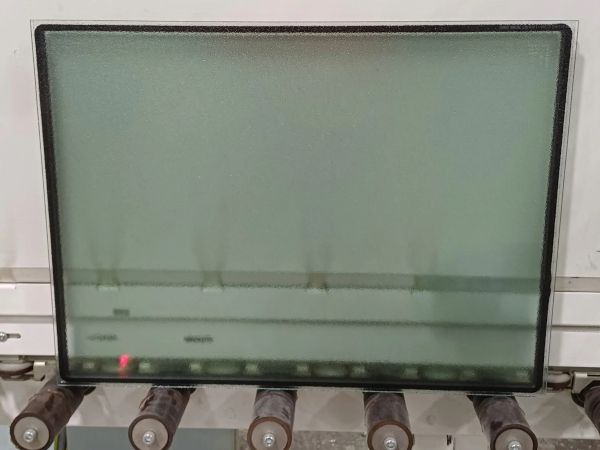

A perfect-looking IGU can still fail. Explore why visual inspection alone is not enough to ensure real IGU performance.

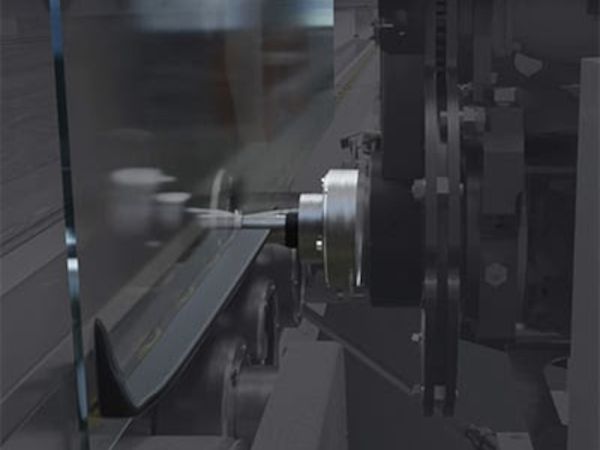

The SplitFin is a vertical processing line for flat glass with two processing towers: EPS-B for edge processing and MRX-B for internal processing.

Discover how automated TPA application ensures accuracy, speed and reliable processing – even in large-format production.

On 6 and 7 November, LiSEC welcomed more than 60 customers from Central and Eastern Europe and the Commonwealth of Independent States (CIS) region to Seitenstetten.

LiSEC is meeting challenges and emerging trends with innovative concepts and custom solutions.

Sparklike continues to strengthen its global presence, connecting with industry professionals and showcasing its innovative gas measurement solutions for insulating glass (IGU) quality assurance.

From the GlassBuild 2025 show floor in Orlando, Forel & Quanex are highlighting the innovative collaboration that is bringing automation and spacer performance to the next level.

New model FG for fast grinding and simultaneous edge seaming.

Visitors can find the Forel team at Booth #18085 (South Building), where they will share the latest updates on Forel’s advanced glass processing technologies, 100% Made in Italy.

Articles

A new study explores how smarter structural design and adhesive optimization in glass-metal façades can significantly cut embodied carbon while maintaining performance and integrity.

Understanding how glazing systems behave under blast conditions is essential for designing safer, more resilient façades.

In this seventh episode, we’re exploring how dynamic mixing enhances sealing quality and speed.

In this sixth episode, the focus is on how to assemble and gas-fill IG units synchronously.

In this fifth episode, the focus is on how the new TPS® PRO Applicator achieves up to 15% higher yield.

How do you move glass plates without a single scratch?

By Errol Bull, P.E., CSI, an Application Development Leader at Momentive Performance Materials Inc. Member: IIBEC, ASTM C24, ISO TC59/SC8

Discover how TPS® boosts IGU longevity and energy performance in this Glastory blog and download the presentation.

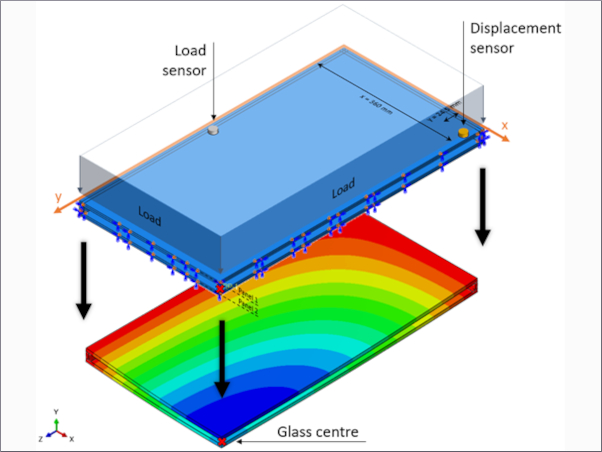

In this paper, the behaviour of various Insulating Glass Units (IGUs) is examined under the influence of quasi-static uniform wind pressure and weather actions.

In this latest Glastory blog, Uwe Risle explains why thin triple IG units are gaining popularity and what the key differences are between thin triple IGUs and other insulating glass types.

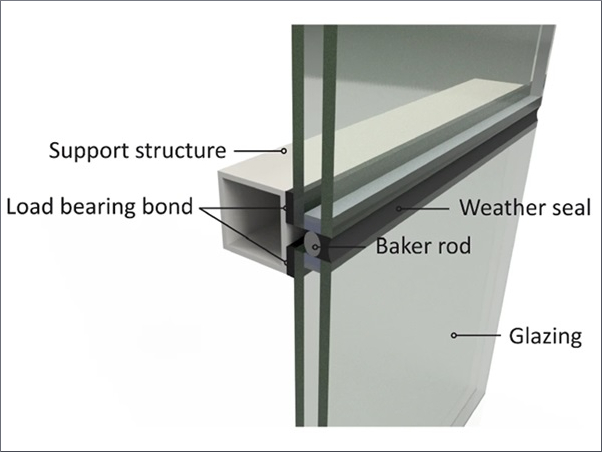

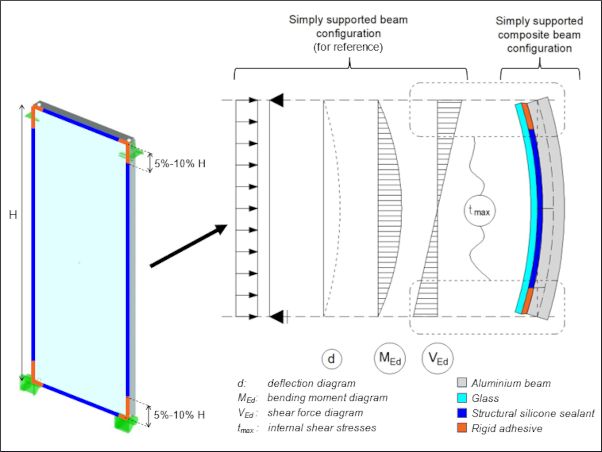

Structural sealant glazing systems are increasingly used in transparent glass constructions, but designing bonded joints still relies on outdated safety concepts, despite recent research proving the reliability of hyperelastic silicone bonds.

A Composite Approach in the Design of Glass-Aluminium Facades to Minimise Embodied Carbon Emissions

COMPANIES

Products

Sparklike Oy – Your IG Quality Assurance

Sparklike Oy – Your IG Quality Assurance