Date: 23 July 2025

Around 60 glass processing specialists from Germany, Austria, Switzerland, the Netherlands and Belgium came together to talk about current developments and practical solutions.

The programme offered exciting presentations on the latest LiSEC technologies and an exclusive factory visit to Energy Glas in Wolfhagen, close to Kassel. The seven specialist presentations concentrated on key topics in glass processing: Spacer application, system planning, automation, glass processing, software solutions, logistics processes and sustainability were discussed.

The highlights of the presentations

Thanks to modern simulation technologies in which almost all LiSEC machines will be able to be depicted in the future, production concepts can already be simulated realistically in the planning phase – including cycle times, material flows and logistical processes. LiSEC presented two concrete implementations based on this: The “perfect factory” represents a highly automated line with maximum throughput, while the “complex factory” offers a flexible solution to produce challenging special glass in narrow spaces.

In the insulating glass production area, new solutions for all common spacer types were presented, including the FSI-A frame mounting station with assembly aid and the FSA-A flexible spacer applicator. The integrated climbing aids on the front and rear of the FSI-A enable large frames to be set conveniently, as well as cleaning and inspecting the glass lites sheets.

LiSEC also has novel offerings in the glass edge processing area. New procedures from edge grinding to laser processing enable more precise, faster and more versatile processing. The new LiTEC slider technology ensures perfect edges, even of the breakage is poor, and therefore reduces scrap and the associated costs. In addition, new applications in the area of laser processing for glass were presented – including precise drilling (LDP-A), structured surface processing and edge deletion (LSP-A) and permanent glass labelling (LMS-A). For more information, see: www.lisec.com/solutions/individual-machines

The IG Sort systems fully automate handling at the end of the insulating glass line. Thanks to the use of robots, continuous production is ensured, shipping racks are detected automatically and units are set down with constant precision – without deformation even with thermoplastic spacers. In addition, the IG Sort systems provide an innovative option for temporary storage of wet insulating glass units, automatic ejection of rejected parts and autonomous handling of remakes. The result: higher productivity, more flexibility and fewer manual interventions.

LiSEC relies on resource-saving machine solutions such as the IGD-A or the LiTEC Temperature Control, which reduce energy and water consumption, pollutant emissions and material usage. This year, LiSEC receiver the EcoVadis bronze medal for outstanding sustainability solutions. Digital tools such as the free “grafana” software tool are used to analyse consumption data and to optimise new prototypes.

Various approaches for increasing efficiency and automation were presented in the glass cutting area. A particular highlight was the new VSL-A double-bridge solution that features dynamic, self-learning load optimisation. For more information, see: www.youtube.com/watch

In production planning, adaptive optimisation for efficiency was presented: it analyses data continuously, such as order details, error messages and downtimes, and creates the best production plan dynamically in order to meet delivery deadlines despite faults.

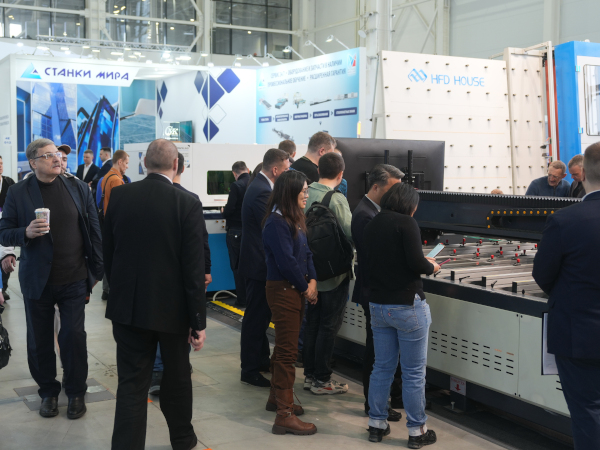

Exclusive factory visit to Energy Glas

A particular highlight was the visit to Energy Glas in Wolfhagen. The company uses modern LiSEC technology to produce highly-insulating glass. The factory tour offered interesting insights into the automated processes. The visitors to the Technology Days, including Lothar Schleiner, Operations Manager at Gethke Glas Gronau GmbH, were very impressed by the LiSEC systems: “I found the LSG glass cutting on the VSL-A that processes glass remnants of just 2 cm particularly interesting – that’s really small. It was also really impressive to see the entire organisation and automation of production in process.”

The LiSEC Technology Days 2025 showed impressively how dynamic, innovative and forward-looking the glass industry really is. With insightful specialist presentations, exciting product innovations and an inspiring factory visit, the event offered valuable stimuli for the future.

600450

600450

Add new comment