Tempered Glass Technology

News

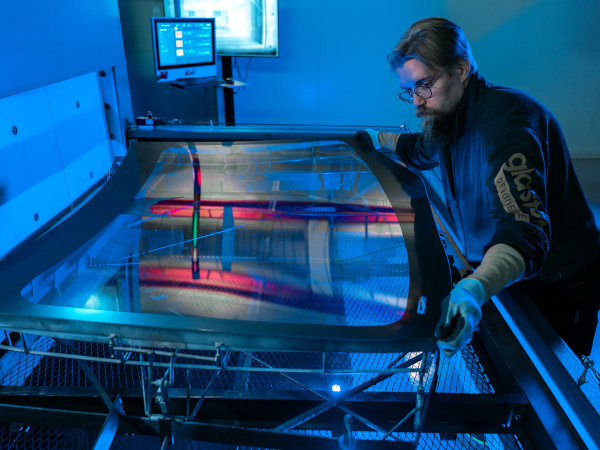

Project Scope: Inspection for All Types of Distortion, Anisotropy, Edge Stress, and Surface Quality.

Glaston supports the more demanding automotive glass market with advanced processing technologies and consistently superior optics.

Satinal, a leading manufacturing company in the glass industry, has officially announced its participation in the upcoming Glass Expo Hawaii 2026, scheduled to take place in Honolulu from February 4-6.

As 2025 draws to a close, it’s a good time to reflect on business. We know for most glass processors, this has not been the easiest year.

Soft market continued, profitability supported by productivity improvements.

Knowing its roots helps shape the future. From Tamglass in the 1970s to Glaston today, the company’s windshield-bending journey has been driven by curiosity, craftsmanship and teamwork.

From January 20 to 23, 2026, NorthGlass participated in Swissbau at Messe Basel, one of the world’s leading trade fairs for the building and construction materials industry.

NorthGlass showcased its innovation in architectural glass at CTBUH 2025, demonstrating how cutting-edge technology and design push the boundaries of high-rise sustainability and aesthetics.

Henan Party Secretary Liu Ning visited Luoyang NorthGlass, praising its innovation and encouraging the company to continue driving the growth of the province’s high-end manufacturing cluster.

NorthGlass exhibits made a stunning debut at Fenestration BAU China (FBC).

DAY 3 of Glasstech Asia and Fenestration Asia is in full swing, and the excitement just keeps growing!

The excitement carries on at Glasstech Asia and Fenestration Asia 2025!

Glasstech Asia & Fenestration Asia 2025 opens today in Jakarta, uniting global glass and façade industry leaders to explore innovation and sustainability.

Tomorrow, the global glass and façade community will gather for GAFA 2025 - a premier platform for innovation, collaboration, and business exchange.

Preparations are in full swing! The exhibition halls at ICE BSD City are transforming as our team and exhibitors set up their booths for Glasstech and Fenestration Asia 2025.

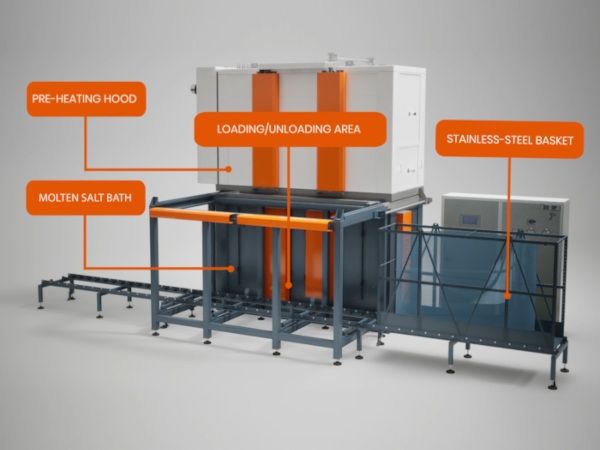

TK S.r.l. showcases how chemical tempering is transforming glass processing with its advanced TK Chemical Temper ovens and new 3D video.

Articles

Reducing energy consumption in glass tempering is no longer optional — and new cooling innovations are making it achievable.

Latest on Glastory by Robert Jenks: Improving your performance for a lifetime - Smart strategies for glass processing line success (Part 2/2)

Smart glass, simplified. Meet OSSE, Organic Semiconductor Materials for Sustainable Electronics, from the University of Turku.

In Part 1 of the new Glastory blog series, the article explores how production uptime becomes a competitive advantage and which strategies help keep operations smooth and businesses strong.

In this seventh episode, we’re exploring how dynamic mixing enhances sealing quality and speed.

At Step Change 2025, ReViSalt demonstrated how its innovations are reshaping the future of glass strengthening.

In this sixth episode, the focus is on how to assemble and gas-fill IG units synchronously.

Fresh from Step Change 2025, Lithium Designers GmbH, the Frankfurt-based innovators transforming façade planning through parametric design and 3D-printed nodes, shared their insights on how technology is reshaping the future of architectural design.

At Step Change 2025, in connection with Glass Performance Days 2025, eLstar Dynamics wowed us with their smart glass tech that dynamically shifts from ultra-dark (0.1% transparency!) to crystal clear (up to 70%).

In this fifth episode, the focus is on how the new TPS® PRO Applicator achieves up to 15% higher yield.

Spontaneous glass breakage caused by nickel sulfide (NiS) inclusions remains a hidden yet critical challenge in architectural glazing, raising important questions about safety, quality, and prevention in modern glass production.

In this ninth episode of #AskGlaston flat tempering series, we explore how to optimize energy efficiency in the case of short loadings.

COMPANIES

Hornos Industriales Pujol

Carrer del Pla, 108-110, Pol. Ind. El Pla

08980 Sant Feliu de Llobregat Barcelona

Spain

Luoyang North Glass Technology Co., Ltd.,

No. 20 Binhe Road, High-tech Development Zone,

Luolong Qu

Luoyang Shi

Henan Sheng, 471003

China