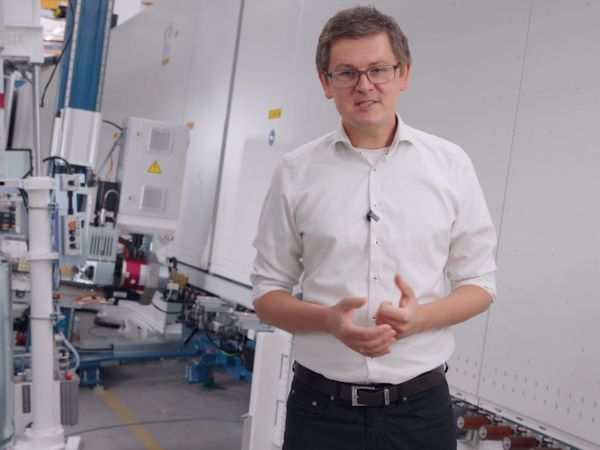

Author: Gennadi | Glaston

Source: www.glastory.net

As the original inventor of TPS® technology, Glaston continuously optimizes the production process by adding innovative features.

At glasstec 2024, we launched the newest TPS® PRO Applicator, which represents the 5th generation since the machine’s introduction to the market in 1995.

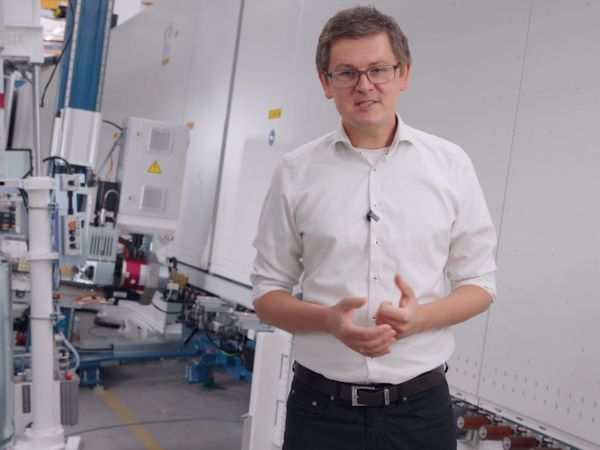

The innovative parallel transport of glass plates in and out of the machine, with no height limitations, results in up to 15% higher yield.

Our exclusive gear pump system guarantees consistent high-precision dosing quality, fast changeovers and uninterrupted 24/7 production thanks to the new master-master drum pump solution.

The specially designed follower plate allows a higher heating capacity and up to 35% improved material output. With an application speed of up to 40 meters per minute, there is no need to slow down for larger glass plates.

The shortest corner bevel joint meets the highest quality requirements. This function is also available as an upgrade kit for TPS® applicators from 2016 onward.

Finally, the automatic adjustment of IG thickness tolerances simplifies window production.

In short – With parallel in-and-out glass transportation, the master-master drum pump and increased heating capacity, the TPS® PRO Applicator achieves up to 15% higher yield.