Peter Lisec Straße 1,

Seitenstetten 3353

Austria

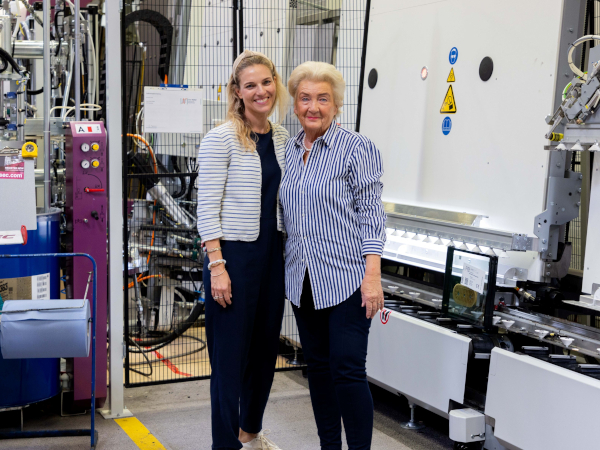

LISEC Austria GmbH

LiSEC is a globally operating group which has been offering innovative individual and complete solutions in the field of flat glass processing and finishing for more than 50 years. The performance portfolio includes machines, software solutions and services.

LiSEC develops and produces glass cutting and sorting systems, individual components and complete production lines for the production of insulating and laminated glass as well as machines for the processing of glass edges and tempering systems. With their reliable technology and intelligent automation solutions, LiSEC sets standards in terms of quality and technology and makes a substantial contribution to the success of their customers.

LiSEC machines and plants are often used for 20 years and longer. Robustness and a long service life are the trademarks of our technology. With custom-made service packages and regular technology updates the plants always remain up-to-date and you can be sure to meet the increasing quality criteria of the market.

BENEFITS:

- Increased efficiency throughout the entire plant lifecycle

- Long service life and robustness

- Flexibly expandable due to a modular construction

- Safe investment

When LiSEC started processing flat glass only a few, often unsatisfactory machines were available. The solution: the required machines were developed in-house. Since then, LiSEC has continuously pushed progress.

In our integrated Research and Development department, and in development partnerships with research institutions and universities, 60 research employees are currently working on new technologies and new solutions for the manifold requirements of the industry.

ACHIEVEMENT:

- More than 250 patents

- 60 research employees

- Integrated Research and Development department

- Innovations focused on practical applications

Our machines and plants for the processing of flat glass are in use for many years, sometimes even for decades. Continuous maintenance and optimization are vital to keep the performance, efficiency and availability on a consistently high level and to ensure the quality of the glass products.

BENEFITS:

- Minimized standstill times through fast support

- Guaranteed availability of spare parts or equivalents – for at least ten years

- Worldwide supply of spare parts

- Employee training directly in the production and at the local training center

- Added value throughout the full lifecycle of your plants

Today, the material glass is a highly functional product which has to meet requirements far beyond form and design. With more than 50 years of operator know-how and two processing locations we are familiar with the needs of flat glass processors like no other plant manufacturer.

BENEFITS:

- Sole system partner with more than 50 years of experience

- Machines and plants tried and tested in real-life operation

- Training and advanced training of your employees

- Leading edge through solutions focused on practical application

Constant development of new glass types, ever increasing quality requirements, cost pressure and much more – we support you all along the line to reliably meet your objectives.

As the only system partner worldwide, we provide all solutions you need for the processing and finishing of flat glass from a single source. Our experts support you with competent advice and accompany you through the entire project.

BENEFITS:

- Engineering, plants, software and service from one single source

- Minimized interfaces – reduced risk

- Optimized process sequences

- Increased end product quality

- A competent partner for all questions

Products

Our professional staff will happily support you with the detail configuration of your customized line solution for insulating, flat or laminated glass. To use your production to its full capability, we offer system-wide software solutions for optimization, production planning, and other applications.

GLASS CUTTING LINE

High-performance system for automatic cutting of float and laminated glass: Combined float / lami glass cutting line

INSULATING GLASS LINE

Insulating glass line for rigid spacer frames

Insulating glass line for flexible spacers

Insulating Glass Line for Thermoplastic Spacers

GLASS PROCESSING LINE

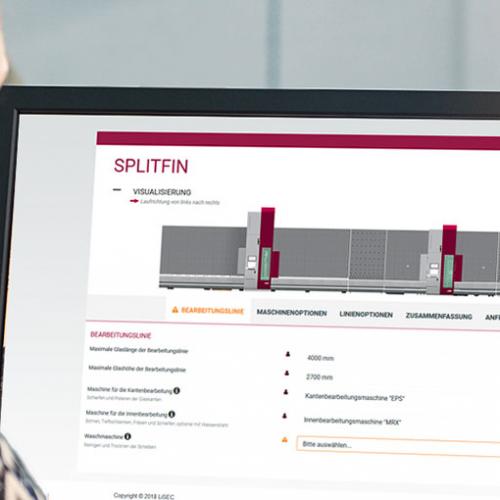

SplitFin: Fully integrated and modular glass processing line

LAMINATED GLASS LINE

We do not only support you in the field of insulating glass production, with the LiSEC insulating glass machines, but also with machines for glass cutting or glass processing, sorting and logistics systems as well as tempering furnaces.

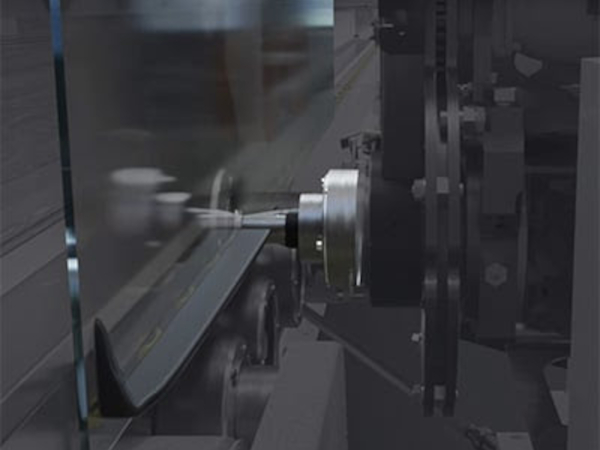

GLASS CUTTING

Proven and innovative cutting systems for every requirement

INSULATING GLASS PRODUCTION

Plants for the entire production process, from compact and robust up to the fully automatic high-end plant network

SORTING & LOGISTICS SYSTEMS

Hands off the glass! Efficient solution for handling glass panes throughout the entire production process

FLAT GLASS PROCESSING

LiSEC processing plants stand for quality and efficiency

Universal Processing (Edge- and Inside Processing)

Water Purification & Treatment Systems

GLASS PROCESSING & WASH

Glass Drilling and Milling Machine

Innodia - Innovative Diamond Tools

QUALITY MANAGEMENT

LiSEC is committed to the quality inspection of individual glass panes, insulating glass units, and processed glass.

TEMPERING

LiSEC’s energy-saving procedure revolutionizes tempering of more resistant thin glass panes down to a thickness of only 1.6 mm.

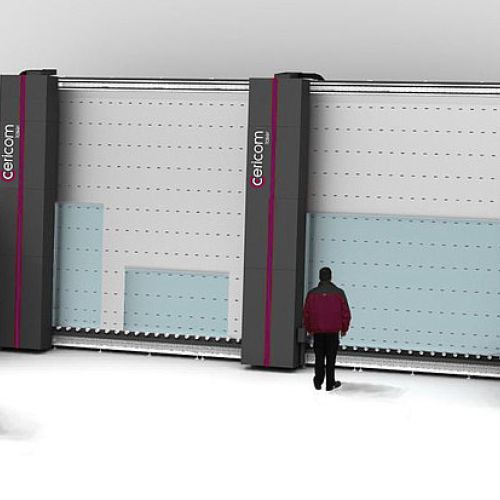

CERICOM - LASER SYSTEMS

Laser systems – Innovation, durability, efficient work and low operating costs

base

The plants of the base series are reduced to the basics and are not only robust but also very easy to operate.

SOFTWARE FOR BUSINESS MANAGEMENT

Innovative software for administration and evaluation of quote and order data

order: Order Management Software

Toolbox for Glass Installations and Mounting: All-inclusive software system for designing, quoting, scheduling and invoicing your glass installations

cadcam: CAD software solution for flat glass processing

scancam: Digitalisation of templates

Business Intelligence & Analytics: Detailed data analysis and business information

SOFTWARE FOR PRODUCTION MANAGEMENT

Production control and glass wastage reduction with just a few clicks

prod: Production Planning Software for the Flat Glass Industry

opt: Software for Glass Cutting Optimisation

easy opt: Single glass optimisation software

tso: True Shape Optimisation Solution

dynopt: Dynamic Glass Cutting Optimisation

oad: Intelligent Glass Cutting Solution to Avoid Defects

prodschedule: Graphical Capacity Scheduling Solution

bar: Georgian Bar Construction Software

reporter: Data Analysis and Reporting Solution for the Glass Industry

label: Label Management Solution

ident: Information and Ready Messaging Terminal at the Production

pack: Graphical Display of Packing Sequence

prodmon: Production Overview at a Glance

delivery: Software Solution for the Dispatch Area

qms: Quality Management Software

SOFTWARE FOR SHOPFLOOR MANAGEMENT

Networking software and machines for an efficient production

assetcheck: Machine Status Monitoring Software

perfectscan: Quality Scanner for Single Sheets and Insulating Glass

autofab: Solution for Automtatic Sorting Systems

Line Management: Control and Monitoring of Insulated Glass Production

mon: Break-out display for glass cutting table

SOFTWARE ON MACHINES

Time-tested software solutions for a state-of-the-art machine utilization

bendvisu: Frame Management Software

HOW DOES IT WORK?

Put together your desired line or processing solution online and try out various details and options. Get a summary of the configuration including visuals and all technical data by e-mail. Only a few days later our sales team will provide you with an actual quote. This can be used as basis for further consultation.

YOUR ADVANTAGES

You can access the configurator quickly and easily from any device (desktop, smartphone, tablet, ...) and print or forward your configuration at any time. New machines and lines are constantly added to the configurator.

GLASTRONIC, THE SPECIALIST FOR PRE-OWNED GLASS PROCESSING MACHINES

LiSEC took over GLASTRONiC in 2016. As part of the LiSEC Group, GLASTRONiC buys and sells pre-owned LiSEC glass processing machines. Our customers appreciate their unbeatable price-performance ratio.

GLASTRONiC guarantees the impeccable operation of pre-owned glass processing machines. This includes the following services:

- Assessment

- Preparation

- Sales

- Commissioning

- Installation

- Service

- Spare Parts Availability

Find all available pre-owned glass processing machines at the following link:

Wherever horizontal alignment of the glass is not required, this system provides you with a powerful laser machine for glass processing.

As the glass panels do not have to be laid horizontally anymore, they can easily be placed on the machine, which makes the whole handling process a lot easier. This means that even door-sized glass formats can be set up on the c-vertica by a single employee.

The glass panels stand on the machine with a 6° inclination and thanks to the use of soft rollers or support elements they are well protected from scratches and other potential damages.

We manufacture the c-vertica systems in various sizes and expansion stages. Upon request, we will gladly send you a non-binding offer with technical data and prices.

APPLICATION

- Decoating

- Glass marking

- Glass frosting

- Sub-surface engraving

- Anti-slip

ADVANTAGES

- Automatic feeding of the discs without physical effort

- The machine can continue to work independently after work and at weekends

LASER ANTI-SLIP: TRANSPARENCY AND HIGH RESISTANCE

The anti-slip laser structuring creates small indentations on all glass surfaces that can be walked on (even with a post-treatment on toughened safety glass). They create a suction effect that prevents slipping when wet, making it a safer option for public areas.

Unlike printed structures, which disappear after a few months, cericom's slip resistance leaves 90% of the glass surface untouched and develops its effect through vacuum. The small depressions are not subject to any significant abrasion and the surface remains easy to clean. The Wismar Materials Testing Institute has certified the slip-resistant glass surfaces produced with cericom laser machines with "R9" and "R10".

The machine underframe is made of heavy steel constructions with milled guideways.

We offer the machine table in closed or open constructions, depending on the main application. Wherever glass has to be processed in a horizontal orientation this is the ideal solution. The c-matrix system can be supplied as a hybrid or single laser version.

You can therefore either engrave the sub-surface with a solid laser, process the surface using a CO² laser or, if you have the hybrid system, you can carry out both applications on one and the same machine thanks to the provision of 2 laser beam sources.

We produce the c-matrix system in various sizes and configurations. We would be pleased to send you a non-binding offer with technical details and prices.

A particular adapter plate enables simple and flexible integration of the lasermarking module into the existing system technology and facilitates maintenance and replacement. The rotatable laser scan head enables variable exit of the laser beam, so that processing can also be carried out can also be carried out simply “overhead”, for example.

It can be used wherever high quality markings are required or copyright is an issue for example, in the marking of safety glass, in the automotive industry, in medical technology or for jewelry and perfumes. c-mark enables easy integration into existing plants and machines and is also available as an alternative “stand-alone solution”.

ADVANTAGES

- Modular, compact and powerful laser etching/scribing and marking

- High marking quality and durability

- Marking directly on the glass

- No weakening of the glass in the marked area

- Easy service

- Electronic readout

- Individual product code for referencing

- Marking often takes less than one second

- For permanent traceability of any kind of visible and almost invisible markings, as graphics, unlimited lines of text in any orientation, bar codes, 2D datamatrix or QR-codes

- Professional software with simple user interface

- Low power consumption

Marking of additional materials possible - Specifically developed for markings on any kind of glass, even tempered glass

- For low and high speed production lines, optionally with “marking on the fly”-technology

- Environmentally friendly and highly cost-effective, no use of any consumables necessary!

- Simple operation, manual (via operating software or foot switch) or automated (via production control system)

- Easy and safe installation and maintenance in production lines or as stand-alone; small and adjustable scan head for more flexibility, easy exchange of laser system based on adjustable mounting plate with preadjusted laser position.

- Use of high-quality laser components in a robust casing ensures maximum service life, proofed in harsh environment installations

This machine enables high precision cutting and drilling of glass within a processing area of 100 x 100 mm2 along arbitrary 2D or 3D curves (based on drawings). Now, it is not only possible to cut materials with thicknesses of 20 mm and more but also to drill holes with diameters down to 200 µm and achieve aspect ratios larger than 1:25. The drilling and cutting and milling processes are completely “dry“. Therefore the laser processes do neither require any water nor the accompanying water recycling systems.

A very narrow kerf width combined with high accuracy and resolution enables cuts that are currently not possible with any conventional glass processing technology. For the first time, the laser-based process used in the c-cut machine enables an effective way for laser milling of glass. For example, countersunk holes, tapered holes and other virtually arbitrary 3D structures can be milled into the glass surface with ease and precision.

APPLICATIONS

- Microelectronics

- Sensors

- Microfluidics

ADVANTAGES

- “Dry” process

- High hole aspect ratio

- Small processing features > 0.2 mm

- High precision and standard versions

- Integration in production lines