Date: 10 December 2025

For more than 50 years, Glas Natter – a family-run company with a long tradition based in Regensburg, Germany – has maintained a close partnership with LiSEC. Its recent investment in the innovative LiSEC SRP-A system once again underscores their shared commitment to digitalisation and greater efficiency.

Glas Natter: Glass with a History

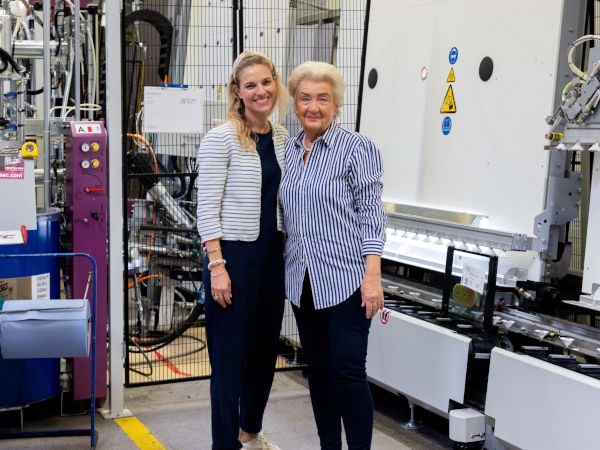

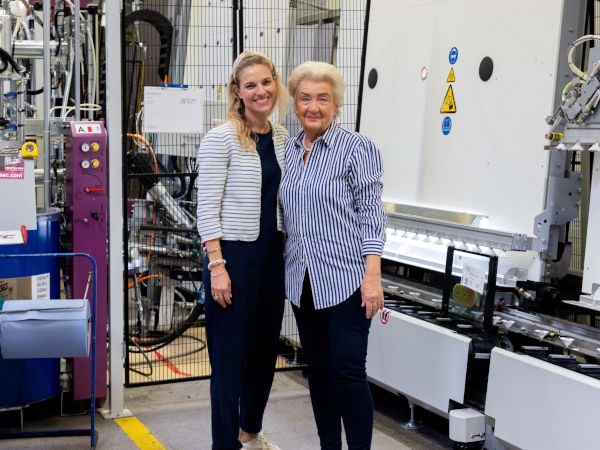

For more than 170 years, Glas Natter has stood for quality, flexibility and a spirit of innovation in glass processing. Today the company is run by the fourth generation – a remarkable continuity that also owes much to the many years of leadership by the current managing director’s mother, Ms Bosse. She played a decisive role in shaping the business and laid the foundation for the modern orientation that distinguishes Glas Natter today.

With around 60 employees, Glas Natter is one of Germany’s established glass processors. The company offers a wide-ranging portfolio that includes insulating glass in various designs – from simple insulating glass units to highly insulating multiple glass units with special coatings. A particularly important area is laminated safety glass (LSG), which is used in around 80 % of all insulating-glass units. Another key pillar of the business is glass wholesale. Glas Natter also produces glass cuttings for a variety of interior applications.

“We see ourselves as a supplier of glass in every form – from single sheets to complex insulating-glass solutions,” explains Barbara Bosse, Managing Director of Glas Natter. “What sets us apart is our flexibility and our ability to deliver even one-off units efficiently and to the highest quality standards.”

Partnership with LiSEC: It’s People Who Make the Difference

Cooperation with LiSEC began when Glas Natter moved to its present site in the 1970s. Since then, LiSEC has been a trusted partner in automating and digitalising production, providing a range of machinery and software solutions. Glas Natter values the close relationship: “We’re always extremely well supported – reliable, competent, and with a knowledgeable contact person available whenever questions arise. That’s really fantastic,” says Ms Bosse. She particularly appreciates the combination of hardware and software from a single source, which makes LiSEC the company’s central point of contact. Over the years Glas Natter has installed a wide array of LiSEC systems – from glass storage and cutting through to processing and insulating-glass production. This continuous setup ensures smooth workflows and high production reliability.

What unites Glas Natter and LiSEC is not only technology but also attitude: “People buy from people – at the end of the day there’s always a person behind the product, and that’s a good thing. We believe in being approachable and human, and I think LiSEC is very similar in that respect – even though there’s a large corporation behind them,” says Barbara Bosse.

LiSEC SRP-A System: Where Innovation Meets Practical Experience

The latest investment – the LiSEC SRP-A system – was commissioned at Glas Natter as one of the first installations of its kind. The SRP-A is a state-of-the-art sealing machine for insulating glass, designed specifically for precise and efficient processing. Its newly developed suction-axis design guides each unit with outstanding stability, making the system ideal for companies that handle both standard formats and complex custom shapes. Thanks to the patented “Full-Support Belt System” technology, the glass is transported safely and gently – even when sealing material protrudes at the corners. The system can process insulating-glass units up to 80 mm thick.

“We’re flexible, we like trying new things, and we have the people who can and want to make them work,” says Managing Director Barbara Bosse, describing her team’s openness to new technologies – a decisive factor in successfully introducing innovations such as the SRP-A system.

Looking Ahead: Digitalisation and Added Value

Glas Natter looks to the future with optimism. Investments in software and AI are high on the agenda, alongside a stronger positioning of glass itself. The managing director’s vision: “I want to help ensure that glass once again gains the recognition it deserves – as a premium material.” The long-standing partnership between Glas Natter and LiSEC demonstrates how technological expertise and mutual trust can work hand in hand over decades. With a machinery fleet that covers everything from glass storage and cutting to processing and insulating-glass production – almost entirely based on LiSEC systems – Glas Natter relies on fully integrated solutions from a single source. The investment in the SRP-A system is another step towards making production more efficient, more digital, and ready for the future. Both companies share a commitment to continuously advancing quality and customer focus, proving that genuine partnership can continue to inspire even after many decades.

600450

600450

Add new comment