Date: 1 October 2025

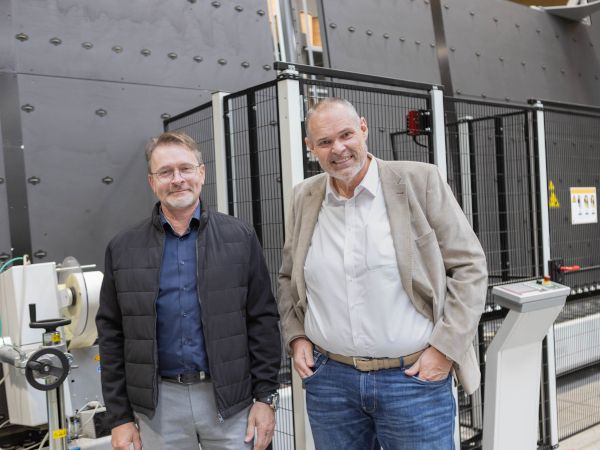

Felbermayer Fenster und Türen Erzeugungs GmbH is located not far from Vienna. The Austrian company was founded in 1963 and is considered a pioneer in automated flat glass processing. To achieve this high level of automation, Felbermayer has relied on LiSEC from the outset and can now look back on the highly efficient production of insulating glass with the maximum quality with a minimum of personnel. 195 people are currently employed on a production area of 22,000 m². Felbermayer is clearly focussing on delivering high-quality products within Austria. The company is well known as a full-service provider for wood, wood/aluminium, plastic and plastic/aluminium windows. Felbermayer is in a class of its own in the fire protection sector with wood/aluminium windows in fire protection class EI-90. The target customers are within the areas of property construction, large-scale residential and social construction as well as commercial construction such as schools.

Successful cooperation with LiSEC: Unique in-house insulating glass production in Austria

In 2021, Helmut Felbermayer decided to produce the insulating glass for window construction himself instead of purchasing it. "I always had the vision of producing the glass for my windows myself", says Helmut Felbermayer. This makes him one of the few window manufacturers in Austria who cover this range of services. To successfully plan and implement the major project of producing his own insulating glass he turned to LiSEC. Mr. Felbermayer had known LiSEC for a long time: "We had been attending glass trade fairs and seeing LiSEC machines live for years, long before we decided to start our own insulating glass production. I am a machine freak at heart and was enthusiastic about the solutions that LiSEC offers right from the outset. When we decided to manufacture insulating glass ourselves, my first stop was LiSEC, because we wanted the products from a full-service provider from whom we could purchase both machines and software." For Felbermayer, LiSEC is one of the most innovative mechanical engineering companies in Austria.

The major project ran smoothly from planning up to installation. A great deal of coordination took place between the two business partners in order to achieve the best possible result. "LiSEC provides excellent advice, and the project development was also very good. The people know their stuff! The installation went off without a hitch", says Helmut Felbermayer about the planning and installation phase. The result is an insulating glass production process that runs fully automatically, from cutting the glass to processing the edges of the glass, assembling the insulating glass up to acceptance of the finished elements, without the need for an operator to intervene. The three production employees only perform a supervisory function while the machines are running. The elimination of manual intervention gives Felbermayer a significant advantage: The quality remains consistently high and glass damage, which often occurs due to manual handling, is avoided. Thanks to the high level of automation, customer complaints have almost completely disappeared. "We are very innovative. We have developed our windows so that they can be produced fully automatically – that is our strength. Extending through the entire production process, the RFID tracking that we use to track the material flow, also makes us unique" says the managing director.

Insight into Felbermayer's modern glass processing with LiSEC systems

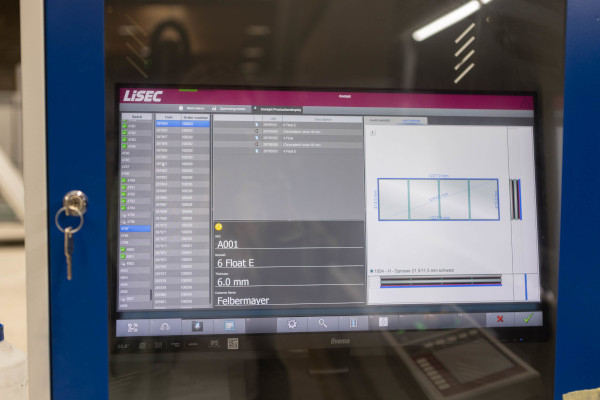

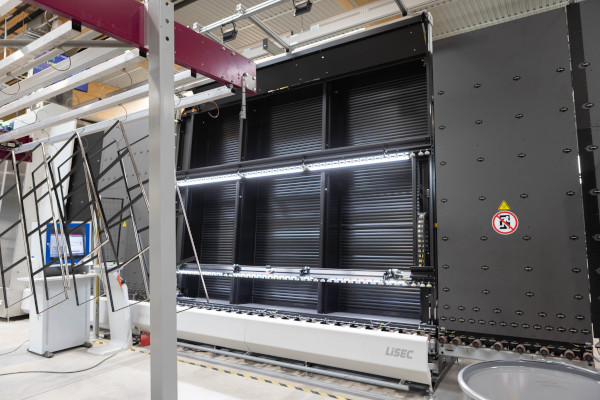

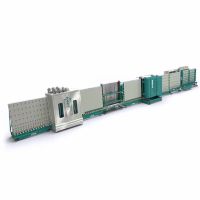

Felbermayer's production hall is an impressive example of automation in glass processing. With a large number of state-of-the-art LiSEC systems, Felbermayer can process LSG, tempered glass and float glass. "Just look at the LiSEC systems, they speak for themselves", adds Helmut Felbermayer about the machinery in production. A separate hall houses a LiSEC PKL system with glass storage racks. This glass feeding system supplies the two LiSEC VSL-A and ESL-RS glass cutting systems. The double-bridge VSL-A laminated glass cutting system with integrated fully automatic X-Y-Z breakout enables efficient and perfect cutting of laminated glass. The glass sheet is placed in a shuttle via the tilt arm of the LiSEC BTA and fed to the edge-seaming system. Parallel to the VSL-A glass cutting line, there is an ESL-RS float glass cutting system for coated glass lites sheets with automatic X-Y-Z breakout and an additional manual breakout table. The float glass sheets are then fed to the edge-seaming line by a shuttle, because at Felbermayer all sheets are seamed, which ensures a high quality of the finished products. After seaming, the sheets are moved into the inspection zone, where they are inspected by the GPS.perfectscan glass scanner. The quality control does not cause any interruptions, thus ensuring continuous production. The LiSEC RHH-A robot system is used for loading and unloading the tempering bed. After the tempering oven, the robot system lifts off the sheets that are passed through a scanner and fed to a buffer. The sheets are then sorted into a buffer. For the owner, the highlight of the production hall is the fully automatic LiSEC insulating glass line, consisting of a TPA-A applicator for thermoplastic spacers, a rotating station, the AGP-A gas filling press, a GPS.perfectscan scanning station for the final quality check, a LiSEC cork applicator, label printer and the VFL-1F sealing machine. The LiSEC TPA-A for the automatic processing of thermoplastic spacers is the heart of the insulating glass line and enables maximum flexibility through seamless switching between different glass dimensions. The stepless width adjustment allows switching between different spacer widths without any waiting time.

Sustainability and innovation: Felbermayer's pursuit of continuous improvement in the window manufacturing industry

"We have been focussing on sustainability for a long time. On sunny days, our production is completely energy self-sufficient thanks to photovoltaics, the glass and glass sheets are recycled and pellets are made from wood waste" explains the managing director. This trend towards sustainability can be noted throughout the window construction industry. Plastic windows are becoming less and less popular whereas the proportion of timber or timber/aluminium windows is increasing. Felbermayer does not predict any disruptive changes to the window product in the near future, but expects continuous growth in larger sheets and sophisticated solutions for sun protection or solar cells in glass. "Our goal for the future is to constantly optimise and advance our processes and products. We always endeavour to have a state-of-the art system and to remain at the cutting edge of technology", states Felbermayer. This striving for constant progress and innovation is a central element of Felbermayer's corporate culture. It enables the company to offer its customers high-quality products while making a positive contribution to environmental protection at the same time.

600450

600450

Add new comment