Date: 17 September 2025

From the bustling terminals of Istanbul Airport to the prestigious Vakıf Bank of Turkey, and the international airports of Kuwait and Turkmenistan — these striking glass facades have something in common. Each one was crafted using custom-made, oversized laminated insulating glass units, produced with precision in Ankara, Turkey by Ardıç Cam. Discover how LiSEC machinery plays a vital role in enabling the production of these extraordinary architectural elements in this success story.

Ardıç Cam’s USP: “Versatility is our core strength”

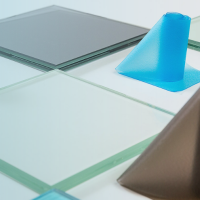

Ardıç Cam specializes in the global supply of highly customized, premium-quality insulated and laminated glass, with lengths of up to 12 meters. Mr Sait Ardıç, General Manager of Ardic Cam, explains: “What sets Ardıç Cam apart is our ability to address any facade-related challenge our clients may encounter. We are capable of realizing any design a customer envisions and can manufacture virtually any type of glass required for facades or other architectural applications. This versatility is our core strength.”

Ardıç Cam’s IG production: LiSEC Delivers the Right Fit

Ardıç Cam’s collaboration with LiSEC began in 2000 with the delivery of a stand-alone argon gas filling machine (GM), which remains in operation at the Kahramankazan, Ankara facility to this day. In 2011, the company expanded its capabilities with the installation of a fully automated insulating glass (IG) line from LiSEC, incorporating a frame bender (BSV), butyl applicator (LBH), and sealing robot (VFL).

What made them choose LiSEC? Mr Ardıç says: “We engaged in discussions and negotiations with several suppliers but ultimately chose LiSEC due to the outstanding quality of their machinery. LiSEC’s solution was the best fit for our needs. In particular, the press and sealing robot stood out for their superior quality and efficiency. Another key advantage is LiSEC’s branch in Turkey, which has significantly improved the speed of technical service and ensured the availability of spare parts thanks to local stock."

Ardıç Cam’s Lamination Production: Advanced Solutions from LiSEC

In 2023, Ardıç Cam purchased two lamination line from LiSEC, marking a key step in upgrading its production capabilities. The decision was backed by extensive market knowledge. Mr Ardıç explains, “We compared LiSEC with other lamination equipment manufacturers and concluded, ‘This is the best solution for us. It's the one that aligns most closely with our needs.’”

For Ardıç Cam, the ability to produce 12-meter insulating glass units without defects, handle thick laminated glass effortlessly, and maintain high production capacity were all essential – and LiSEC met every requirement.

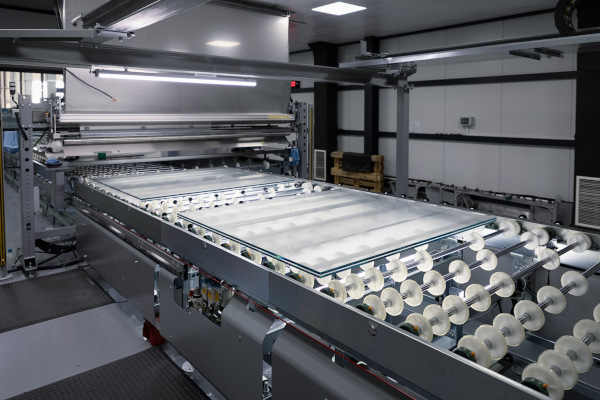

The factory in Sincan, Ankara, is equipped with a 5-meter and a 12-meter lamination line from LiSEC. Both the PlusLam S2650 COMFORT PNM-B26 and MaxLam S33120 PREMIUM PNM-A33/5 lines are designed for efficient laminated glass production. They support automatic glass positioning and transport to the assembly area after manual or semi-automatic loading and fully automatic washing and drying. Each line allows access to 12 stored interlayer foils, which are automatically separated from PE interlayers, unwound and cut to the desired length automatically. The pre-lamination ovens (PNM-B) in both systems use a combination of preheating zones, main heating zones and servo spindle presses to ensure optimal bonding. Heating technologies include radiation, convection and a hybrid of both, with ECO-Heaters integrated for energy efficiency.

The smaller PLUSLAM S2650 COMFORT PNM-B26 handles glass sizes from 400 x 250 mm to 5000 x 2600 mm (length x width). Glass sheets are loaded onto a horizontal table. Parallel glass sheet placement allows to maximize the transport width. Foil laying and trimming are performed manually, with foil remnants stored on a 'foil shuttle' for quick access. The pre-lamination oven includes one preheating zone, two main heating zones, and two servo-spindle presses. A buffer section before the tiltable unloading table ensures optimal throughput.

The larger MAXLAM S33120 PREMIUM PNM-A33/5 accommodates larger glass sizes from 600 x 400 mm to 12000 x 3300 mm (length x width). Glass is loaded via a tilting table. Glass-foil-glass packages are automatically aligned, and stepped laminated glass can also be produced. The 12 stored foils are arranged in a Y-configuration for rapid switching. The assembly table is electrically adjustable in width, and split drives ensure high throughput even for smaller formats. Foil trimming is fully automated for rectangular double-layer laminated glass. The pre-lamination oven includes one preheating zone, five main heating zones, and two servo spindle presses, supporting glass thicknesses up to 100 mm. The laminated glass is unloaded via a tilting table.

Lami-IG Production in Sincan: Where the Pieces Come Together

Around those two lamination lines a seaming line, an automatic frame bending machine, an automatic butyl applicator, and a 12-metre IG production line are installed. These enable the production of highly complex IG units like a 12-metre unit composed of laminated glass on one side and ultra-clear, digitally printed glass on the other, incorporating advanced spacer technology. The factory also features a dedicated spacer system from LiSEC, further enhancing its capability to deliver advanced facade solutions.

Installation at the Sincan site was completed in 2024. Factory Manager Dogukan Gür is highly satisfied with the performance of the new line: “We can produce very complex laminated units without any major problems.” While minor issues are expected with any machinery, the key for Ardıç Cam is reliability and consistency – both of which the LiSEC solution delivers. “The line’s unique combination of forced convection and infrared technology, along with its specially designed nip roller press, allows us to produce nearly any type of laminated glass.”

Automation as a Strategy: Past Success and Future Goals with LiSEC

Reflecting on the collaboration, Mr Ardıç concludes:

We’ve found LiSEC to be a highly reliable and competent partner across product lines, from IG to lamination. Their machinery consistently meets our expectations. LiSEC was the only one to deliver on time. Their fully automated systems allow us to produce complex and uniquely shaped glass units with ease, something that sets us apart from our competition. This capability gives us a clear advantage in handling challenging projects and strengthening our reputation.

Asked about his plans on Ardıç Cam’s dynamic market, Mr Ardıç reveals: "Driven by rising demand for safety glass and advanced coatings like triple-silver solar control glass, we’re aligning our production with market trends through automation. Our facility is equipped with high-performance lines from LiSEC and other suppliers, enabling efficient production of complex, large-format glass."

Ardıç Cam – Company Snapshot

- Founded: 1985

- Employees: Over 400

- Production Area: 87,000 sqm over 3 sites around Ankara – two focus on IGU facades with laminates, one specializes in solar glass

- Export Quota: 60% of production, key markets are US, Europe and Japan

- Target Customers: Large project-based clients, investment companies and government projects (e.g. airports, embassies, hospitals)

- Sustainability Commitment: Zero-waste water policy with in-house treatment and reuse, energy efficiency initiatives underway, plans to install solar panels in the near future

600450

600450

Add new comment