Author: Sakari Palokangas | Glaston

Source: www.glastory.net

Optimizing energy efficiency in low-E glass production begins with mastering the unique heating behavior of coated glass. Low-E coatings reflect infrared radiation, making it harder for heat to penetrate the glass surface evenly. This often leads to longer heating times and higher energy consumption—unless the process is carefully controlled. Challenges in Low-E processing also often lead to lower loading efficiency with Low-E glasses, which also significantly increases energy consumption.

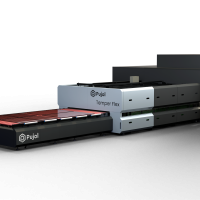

Glaston’s solution lies in combining circulating air convection with intelligent process automation. Our convection technologies ensure that heat is distributed more evenly across the glass surface, even with highly reflective coatings. By utilizing efficient air circulation, the system enhances heat transfer efficiency, thereby reducing the need for excessive radiant heating and lowering overall energy consumption.

When paired with systems like Roller Heat Control and Tempering Autopilot, the benefits multiply. RHC maintains consistent roller temperatures, while Tempering Autopilot dynamically adjusts heating parameters in real time. Together, they ensure that the furnace operates at peak efficiency with high loading efficiency, minimizing energy waste and maximizing throughput.

In short, Glaston’s advanced convection technology, combined with smart automation, enables energy-efficient Low-E production without compromising on quality or productivity.