Via del Lavoro, 1

Erba 22036 CO

Italy

SATINAL SPA

Satinal SpA is an Italian company with a multi-brand architecture (STRATO® Glass Interlayers, TK Glass Machinery and SATINAL Art in Frosting) and it is a global leader in the development, manufacturing and commercialization of glass laminating and glass frosting solutions.

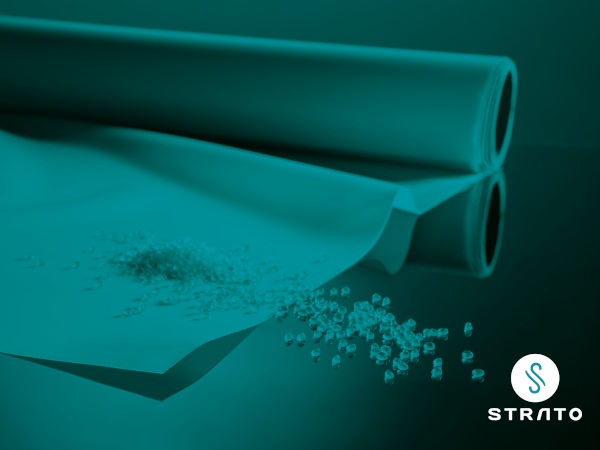

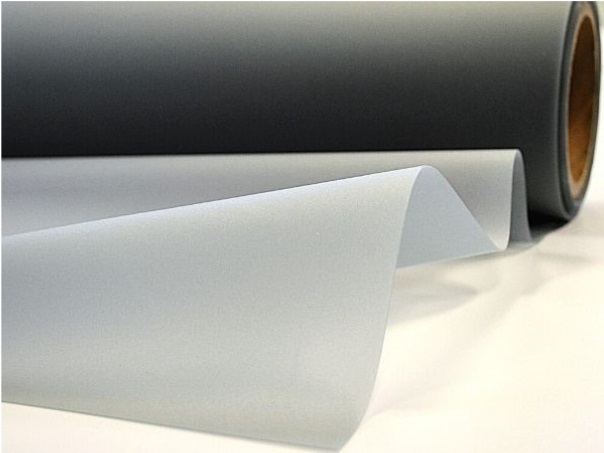

STRATO® is the first EVA glass interlayers brand ever made in Italy by Satinal, processed from the granular raw material into a cast film that is then used to manufacture laminated safety glass both for architecture and interior design, as well as for photovoltaic panels.

TK is a brand specialized in the design and manufacture of high-quality and innovative plants and ovens for glass lamination, chemical temper and Heat Soak.

At the same time, SATINAL is a leader in the production of chemicals and machinery for glass frosting/acid etching.

Founded in 2001, today Satinal is a solid, dynamic and competitive company, looking towards the future while maintaining the strong heritage of the past. The ability to effectively meet any type of need, the constant investments in its R&D S LAB Laboratory, the ability to take the customer by the hand and guide them with confidence towards important growth paths are its real strengths and what enables the group to have greater confidence in the future and the challenges that lie ahead.

Beside the headquarter and manufacturing plant in Italy (Erba - Como), Satinal has branches abroad including United Arab Emirates, North and South America to provide a close customer service in all markets.

Products

STRATO® is a thermosetting material: it is significantly different from the PVB film (Polyvinyl butyral), which is a thermoplastic material. The EVA film creates three-dimensional bonds at molecular level during the lamination process. Furthermore, it is not sensitive to humidity and water, therefore it is not necessary to store it under controlled humidity and temperature conditions.

STRATO® is available in different colours and finishings and it is certified according to European (UNI EN ISO) and American (ANSI - SGCC – ASTM - UL) standards.

Product range:

STRATO® CLEAR

- STRATO® EXTRA CHIARO has a very high light transmission and a full protection against UV radiations higher than 99% thus avoiding the fading of interior furnishings. It increases the stability of laminated glass and gives a sense of lightness and transparency to commercial and residential architecture

- STRATO® PLUS has a higher degree of smoothness and elasticity. It can be laminated with special inserts such as LCD (Smart Glass), PET or fabrics without problems of distortions or air bubbles ensuring

- STRATO® NATURAL UV provides a completely natural and neutral-looking glass while providing exceptional durability when exposed to weathering conditions. It allows a total UV transmission for solar radiation with enhanced permeability for short wave UV A and UV B radiation

STRATO® FROST

- STRATO® LEGGERO provides a veiled frosted effect (light transmission 60-65%), creating a product that can be integrated into any architectural project without affecting its style.

- STRATO® SATINATO allows daylight (light transmission 20-25%) to cross naturally through the interiors of residential and commercial buildings, while at the same time safeguarding privacy.

- STRATO® LATTE gives the glass a glossy, semi-opaque effect (light transmission 2%), allowing a glimpse of the shapes of objects. It captures and diffuses the light into the space, without creating reflections.

STRATO® COLOUR

- STRATO® BIANCO is the best solution for designers who want to create bright, white, and opaque glass elements (light transmission 0%). STRATO® BIANCO ensures the maximum colour uniformity and UV shielding

- STRATO® NERO can give surprising effects, ensuring a sophisticated and unique touch. It also gives the glass a uniform coverage (light transmission 0%)

- STRATO® AZZURRO MEDITERRANEO allows light and color effects on both exterior facades and interior furnishings and is characterized by a transparent color and allows the glass to integrate itself into any architecture, adding an evocative touch

- BRONZO SICILIA is characterized by a transparent color and allows the glass to integrate into any architecture, adding an evocative touch

- GRIGIO DOLOMITI expresses the transition from global efficiency to local resilience, the disruption of global supply chains and the decoupling of economies

- STRATO® VERDE TOSCANA responds to the new trends of sustainability, proximity to nature and routine changes: a revolution of what we do and how we do it. Expresses a new concept of home-office, integrated with nature. It is characterized by a transparent color and allows the glass to integrate into any architecture, adding an evocative touch

- STRATO® LAVA: Transparent Red enchants with its seductive beauty, evoking an aura of passion and sensuality. Its transparency reveals a delicate depth, creating a play of light and color that captures the eye and ignites the imagination

- STRATO® SAND: Transparent Yellow evoking the warm and enveloping charm of the desert. Its golden shades recall the sun-kissed sand, creating a welcoming and reassuring atmosphere

- STRATO® STORM: Transparent Purple captivates with its delicate beauty, evoking an aura of mystery and fascination. Its transparency allows light to shine through, creating a play of shades that captures the eye and sparks the imagination

- STRATO® FOG: Transparent Black exudes an air of enigmatic elegance, captivating with its smoky depth and subtle iridescence. It allows light to pass through, revealing a hidden world of shadows and reflections that intrigue and inspire

- STRATO® ROSE: Transparent Rose evoking the warm and inviting tints of a sunset. It is reminiscent of the soft, glowing light of the setting sun

- STRATO® TANGERINE: a tone that echoes the innate desire for closeness and connection, a colour that radiates warmth and modern elegance. A shade that resonates with compassion, offers a tactile embrace, and effortlessly unites youth with timelessness

- STRATO® MOONSTONE: a blend that creates a whimsical and enchanting color that captures the imagination

- STRATO® AQUAMARINE: this color combination exudes sophisticated elegance, making it a perfect choice for those seeking to create a luxurious and inviting atmosphere

- STRATO® OCEAN: this fusion of generates a vibrant harmony that evokes the freshness of nature and the energy of the sea

STRATO® SOLAR CONTROL

- STRATO® FRESCO is a new generation of high-performance EVA film. It has been formulated to give efficient solar control properties to laminated safety glass compared to clear monolithic glass and conventional clear EVA films

STRATO® BIRD FRIENDLY combines the benefits of laminated safety glass with a design that protects birdlife. STRATO® has developed its proprietary and unique extrusion technology in order to design different types of patterns on the EVA film, including lines, dots and gradients which can be customized depending on the level of coverage achieve

STRATO® STRUCTURAL

- STRATO® SENTINEL is the structural interlayer par excellence produced by Satinal. COnforming to the EN 16613 standards gives strength to the laminated glass and unbeatable post-breakage performance.

STRATO® SENTINEL has also excellent transparency properties, acoustic insulation, UV protection and open-edge stability.

- STRATO® RIGIDO is a special structural interlayer that ensures one of the highest degree of protection against strong impacts. Even if the glass component breaks, the laminated structure is not weakened, so the stability and safety of the product are preserved. STRATO® RIGIDO must be laminated with two sheets of STRATO® EVA film, so the mechanical, adhesive and optical properties can be achieved.

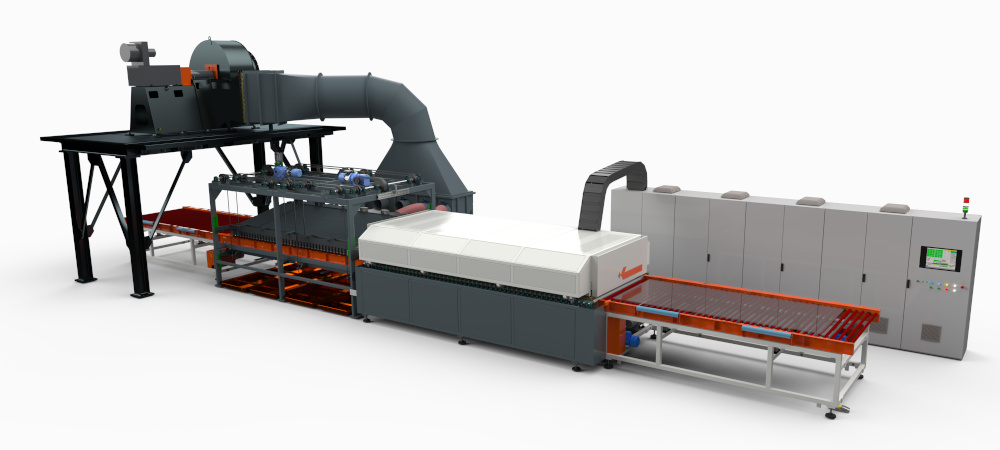

TK Convection is an innovative fast curing and fast cooling laminating oven for high production volumes, interlayer flexibility and lower operating cost. It allows laminating without the use of autoclave.

The modular system allows quick and easy loading of the trolleys for laminating or for HST processes.

- up to a maximum of 6 trays

- aluminium support surface

- high capacity hot air circulation heating system

- forced cooling system

- maximum temperature uniformity

- adjustment of the temperature with thermocouple connected to a digital temperature controller

- vacuum circuit with highly efficient oil pump

- possibility to adjust the vacuum based on the type of materials

- possibility to laminate flat and curved glass without using disposable bag

- silicone membranes with quick Lock Seal closing system

TK Lamijet product range is the perfect solution for customers who need to implement small productions, tests and samplings.

- support surface in aluminium sheet

- temperature control through thermocouples connected to a thermo-computer

- temperature control in independent zones

- heaters placed above and below the working surface. The resistances of the lower surface are assembled on an extractable frame for maintenance

- maximum temperature uniformity

- heating system with infrared heating elements

- ceramic spacer

- copper bar

- heating chamber coated with dust proof low thermal inertia calcium silicate sheets with a max temperature of 500°C

The design of Lamijet Breva is the synthesis of technical knowledge acquired through years of design and construction of glass laminating ovens.

The peculiarities of this system are the speed of lamination and the lamination of EVA, PVB and TPU,

without using any autoclave, which allows to quickly meet any production requirement.

With the new technology applied to Lamijet Breva cycle times can be reduced by 50%.

This oven is suitable for those customers who do not have high productive capacity but however want to

keep an adequate production.

TK ovens have a low energy consumption compared to the average of ovens produced and marketed internationally.

By the chemical tempering it is possible to temper glass with thickness minimum 0,5 mm and also glass with particular geometric shape, maintaining a high optical quality.

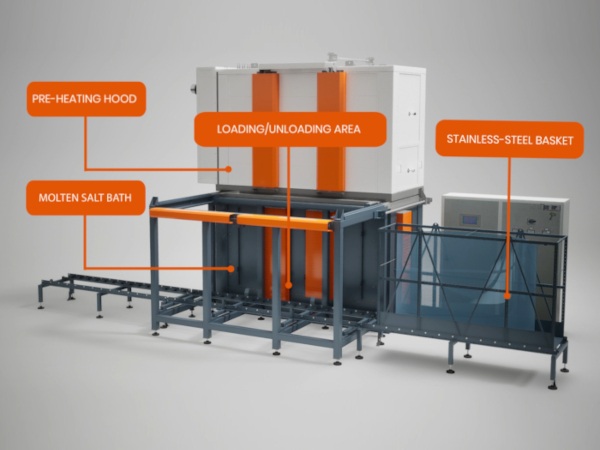

Feature:

• Electrical heating

• Touch screen operator’s panel programmable

• Salts melting tank in thick stainless steel

• Energy lack security system - UPS

• Pre-heating hood

• Electromechanical glass lifting system

• Maximum temperature 500°C

Standard models:

• CT 75 max. glass dim. mm 600x550 (23”x21”)

• CT 200 max. glass dim. mm 2000x1000 (78”x39)

• CT 240 max. glass dim. mm 2000x1300 (78”x51”)

• CT 320 max. glass dim. mm 3200x2200 (126”x86”)

• CT 360 max. glass dim. mm 4000x2500 (157”x98”)

Contact information:

For inquiries please send an email at service@tkitaly.com

Heat Soak Test (HST) oven represents the ideal means to comply with the safety rules concerning the use of tempered glasses.

It prevents spontaneous breakage of tempered glass for excess nickel Sulphur inclusions.

Models:

• 300 Glass dimensions mm 3600x2000 (142”x79”)

• 400 Glass dimensions mm 4000x2000 (157”x79”)

• 450 Glass dimensions mm 4500x2500 (177”x99”)

• 500 Glass dimensions mm 5000x2800 (197”x110”)

• 600 Glass dimensions mm 6000x3300 (236”x130”)

Contact information:

For inquiries please send an email at service@tkitaly.com

The oscillating Master temper ovens cover a size range suitable to meet any production requirements.

The lines are equipped with all the process control technologies in order to always guarantee the best quality.

They are highly productive, extremely reliable, with low power consumption and easy setting of the processing parameters.

All TK ovens are equipped with a remote control system, which allows to verify real time oven conditions.

5-year warranty on resistors

Ceramic rollers in fused silica

Ceramic rollers handling by double belts

Heating elements installed on the upper and lower layer of the section for a temperature uniformity

Many independent heating zones PLC controlled

Blowers groups driven by D.C. motors with inverter

Vertical independent adjustment of the blowing ducts

Independent pressure checking for each blowing duct

The EASY TEMPER oven is designed for the flat small-sized glass with dimensions from 20x30mm up to 80×100 mm.

Feature:

• Highly productive

• Extremely reliable

• Low power consumption

• Easy setting of the processing parameters

Models:

• 35/65 Bed size mm 350x650 (14”x26”)

• 70/100 Bed size mm 700x1000 (28”x40”)

• 100/190 Bed size mm 1000x1900 (40”x75”)

• 100/240 Bed size mm 1000x2400 (40”x95”)

Contact information:

For inquiries please send an email at service@tkitaly.com

The ovens of the Star Temper series are designed to satisfy the requirements of small and medium sized glass companies while maintaining high production levels and granting maximum simplicity of the setting of the working parameters.

Feature:

The heating system can be radiant or combined convection and radiation heating systems.

Models:

• 13/24 Bed size mm 1300x2400 (51”x95”)

• 13/30 Bed size mm 1300x3000 (51”x118”)

Contact information:

For inquiries please send an email at service@tkitaly.com