Date: 21 July 2025

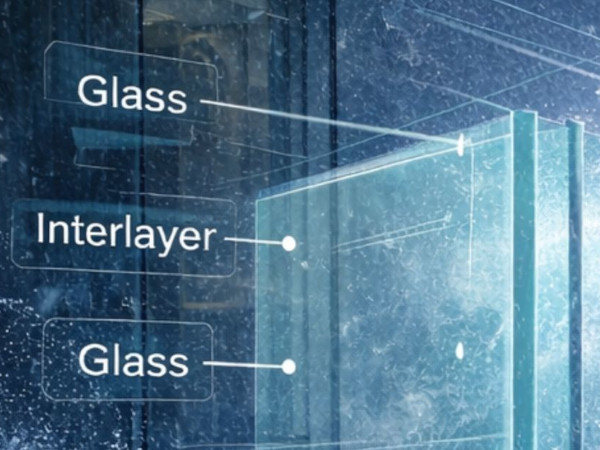

Satinal S.p.A. has announced the successful installation of a new co-extrusion line at its headquarters in Erba, Italy. This state-of-the-art facility is dedicated to the production of STRATO® EVA, POE, and EPE encapsulants for solar PV modules, marking a monumental achievement for the company and the European solar industry. Indeed, the new co-extrusion line will be also strategic for the production of STRATO® acoustic interlayers, specific tri-layers films designed with high-performing insulation properties, particularly in demand and highly relevant for architectural purposes. The core benefit of a EVA tri-layer interlayer system lies in its engineered composition. Unlike single-layer interlayers, tri-layer systems consist of two rigid outer layers sandwiching a soft, viscoelastic core. This specific configuration is meticulously designed to optimize sound damping across a broad frequency range.

The co-extrusion line, positioned alongside two existing extrusion lines that currently produce interlayers for architectural safety glass, significantly expands Satinal's product portfolio and strengthens its international client base. What makes this technology so revolutionary is its ability to combine two or more polymeric materials into a single, multi-layered product. Unlike traditional extrusion, which uses only one material, co-extrusion allows for the creation of products with specific and enhanced properties by uniting the characteristics of different materials within a single structure. This advanced manufacturing system positions Satinal at the forefront of innovation as the first in Europe to harness this capability for solar encapsulants.

This new production plant is just the first of four planned installations for Satinal's STRATO® Solar PV Encapsulants division, with subsequent lines expected to come online starting in the second half of this year. This ambitious expansion underscores Satinal's commitment to meeting the growing demand for high-performance products and solidifying its leadership in the market. As of today, Satinal stands as a leading company manufacturing solar PV encapsulants and interlayers for safety glass lamination in Europe.

The integration of the co-extrusion technology brings a multitude of benefits for Satinal and its customers:

- Versatility: the line's ability to co-extrude EVA, POE, and EPE encapsulants simultaneously offers important flexibility in product development and caters to a wider range of application needs

- Enhanced product performance: co-extrusion allows for the creation of multi-layered encapsulants with tailored properties, leading to improved adhesion, durability, UV resistance, and overall performance of the final laminated products. This is particularly crucial for the longevity and efficiency of photovoltaic modules

- Reduced environmental impact: by optimizing material usage and potentially enabling thinner encapsulant layers with enhanced performance, the new line contributes to a more sustainable manufacturing process

The new investment is a testament to Satinal relentless pursuit of innovation and its commitment to providing customers with the highest quality and most versatile solutions on the market.

This is just the beginning, as Satinal is looking forward to bringing three more extrusion lines online, further strengthening its position as a key player in the global encapsulants landscape.

Contacts:

+39 031 870573

info@satinal.it

www.satinal.it

600450

600450

Add new comment