Date: 12 February 2026

The glass industry is undergoing a clear transformation, moving from traditional EVA lamination ovens to universal lamination systems designed for flexibility and scalable productivity.

With the launch of the TK Lamijet Hybrid Pro, TK introduces a solution that goes far beyond a simple equipment upgrade. This new range represents a strategic approach to lamination, delivering a comprehensive and integrated lamination line experience.

One oven, all interlayers. The versatility of a universal system

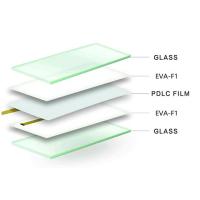

The core principle driving TK is the ambitious goal of having one single oven to laminate every type of material. Modern processors increasingly require the flexibility to handle EVA, PVB, SGP, TPU and complex multi-laminated glass without having to switch machines after a few years. This makes the Hybrid Pro a future-proof investment; even for those focusing on lamination with a specific interlayer type today, the system ensures they are ready to meet the sophisticated architectural demands of tomorrow.

TK hybrid technology

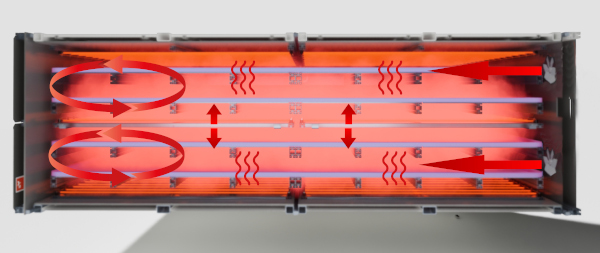

The "Hybrid" designation is a testament to a significant technical step forward. By combining radiation and convection heating technology, the Lamijet Hybrid Pro achieves exclusive process stability. This dual-system approach ensures perfect thermal distribution across all glass types and optimizes heating cycles, significantly increasing productivity and allowing high-performance interlayers to be easly processed.

Heating system

The heating performance is driven by a multizone system for accurate temperature control; each heating element consists of a high-grade conductive material that efficiently dissipates electricity into heat. By managing the power through multiple independent heating zones, the oven achieves a consistently homogeneous performance.

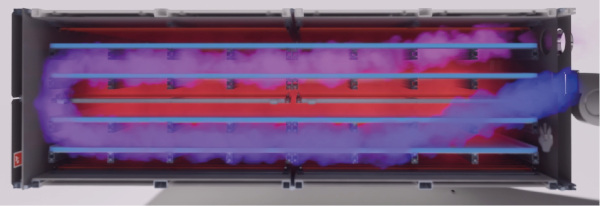

Fast cooling system

Recognizing that the end of the laminating cycle is critical for glass quality, a forced cooling system is essential for achieving superior transparency and structural integrity in laminated glass. This technology significantly reduces the lamination cycle time, also enabling the delivery of finished products to end customers faster.

Furthermore, the TK ovens feature industry-leading thermal insulation. This high-performance insulation ensures:

- Minimal heat dissipation: keeping the heat inside the chamber where it belongs

- Reduced energy costs: lower electricity loss leads directly to a reduction in management and operational costs

- Sustainable manufacturing: a lower environmental impact through optimized energy consumption

TKonnect 4.0 and PLC control: smart, intuitive production management

The TKonnect 4.0 system, combined with TK’s intuitive PLC control, transforms the Lamijet Hybrid Pro into a smart, data-driven lamination system. Operators can monitor and control production cycles remotely via computer or smartphone, ensuring total traceability, consistent quality standards and real-time supervision of production lines. The intuitive PLC interface simplifies complex operations, improving interaction between operator and machine, reducing errors and enhancing daily workflow. The result is a reliable, connected and user-friendly control environment that supports efficient production, operator comfort, remote assistance, and long-term process stability.

An efficient alternative to autoclave systems

Autoclave lamination requires high initial investment, significant operating costs, and considerable plant space. The TK Lamijet Hybrid Pro offers an efficient alternative, capable of covering a huge range of laminated glass applications with significantly lower investment, energy consumption, and footprint.

Thanks to its precise process control, the system enables the production of high-quality laminated glass with greater operational flexibility. Unlike autoclave systems, efficiency does not depend on full loads: the Lamijet Hybrid Pro allows profitable production even with small batches, optimizing time, costs, and responsiveness to market demand.

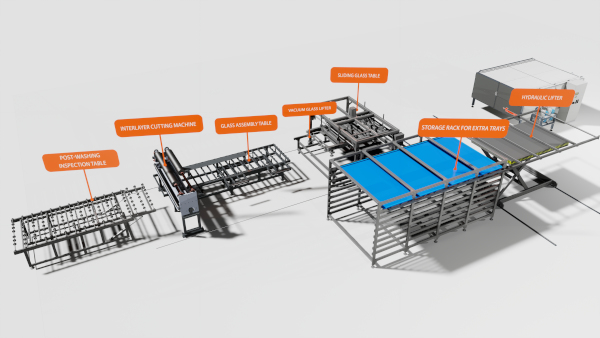

Modular scalability: an investment designed to grow

TK has structured the Lamijet range into two distinct tiers to align with different production goals. The Hybrid Pro serves as the premium universal version. Because every TK Lamijet oven is built on a modular concept, the system can grow alongside your business. TK Customers can start with a single tray and later upgrade to scaled multi-tray configuration or add automated storage, protecting their initial investment over the long term.

Automation and workflow integration

In today’s market, processors are looking for a seamless workflow rather than just a standalone machine. The TK Hybrid Pro is designed to function as a semi-automatic or fully automatic lamination line, integrating motorized infeed systems and PLC-managed tray swapping. By automatically exchanging a finished load with a prepared tray from the storage, the system reduces human error and maximizes uptime.

Built for industrial endurance

Beyond its intelligent software, the TK Hybrid Pro is engineered for physical endurance and continuous production. Built exclusively with high-quality European components, the machine is fully Industry 5.0 ready and compatible with smart factory IoT requirements

A definitive market statement

Ultimately, the TK Lamijet Hybrid Pro is a statement of intent for the future of glass. It offers the ideal balance between advanced automation and the security of a universal system, all while maintaining the reliability for which TK is known.

TK is redefining the modern workspace by proving that industrial power and aesthetic elegance are not mutually exclusive. The redesigned structure of TK Lamijet ovens, together with the hybrid technology already inherent in the DNA of these models, now boasts an exclusive aesthetic, moving away from traditional industrial appearances with sleek details and cleaner geometric shapes. This update can be implemented on all TK ovens, ensuring that the machinery integrate seamlessly into the most advanced production environments, standing as the new benchmark for both technological performance and refined industrial design in the safety glass sector.

Contacts:

ask@tkitaly.com

+39 031 3574873

tkitaly.com

600450

600450

Add new comment