Carrer del Pla, 108-110, Pol. Ind. El Pla

Sant Feliu de Llobregat 08980 Barcelona

Spain

Hornos Industriales Pujol

Find us on:

Founded in 1911 and managed by the fourth generation of the Pujol family, the 5,000 m2 Hornos Industriales Pujol plant is located in Sant Feliu de Llobregat, Catalonia, Spain. It centres its activity on the manufacture of ovens and machinery primarily for the glass, ceramics, metallurgical, and chemical sectors. In the last 20 years it has become an international specialist in the production EVA glass laminating ovens.

Hornos Industriales Pujol is the only manufacturer in the world that has developed an oven capable of laminating PVB without a climate chamber or an autoclave, whilst offering short curing cycles for architectural EVA. This translates into a 40% reduction in the cost of machinery and cost per unit produced.

Our Mission

To constantly develop heat treatment technologies whatever their application; to create technological leadership.

Our Vision

Constant innovation, improvement, and optimisation.

Our Values

Passion, responsibility, commitment and the capacity to adapt to a changing world and transformation are our main hallmarks.

Products

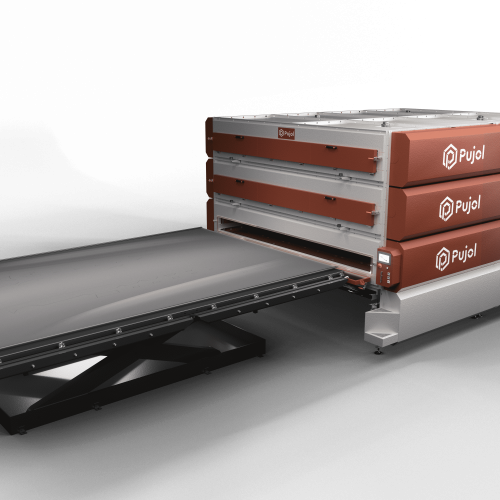

The LAM-PRO seiers ovens has been developed for companies seeking to achieve high performance at a low investment in mind, without compromising with it the excellent quality of the end product.

The LAM-PRO series incorporates unique and innovative features that make it a highly reliable solution.

- Flexibility: Independent isolated work chambers, maximum heat distribution and energy efficiency, resulting in ultra-fast work cycles and a very low specific energy cost per sqm of laminated glass.

- Productivity: Automatic rapid cooling system thanks to our optimized airflow design, the cold air inflow is distributed quickly and uniformly inside the chamber by a set of high pressure fans located at the rear of the oven. The TOP range consists of Pre-Vacuum Bottom Buffer + fast cooling.

- Software control system: Our highly customizable and full featured programmer and HMI allows to keep a continuous close watch of all key process variables such as: temperature- time segments, ramp functions, vacuum status, pressure level, cooling sequence or clock timers.

- Uniformity: Distributed double-layer radiation system that is reinforced with an air homogenization convection equipment by impulse fans “Pujol Impeller Convection System®”, this translates into a homogenization of the heat in the chamber of +/- 3º C.

- Ergoniomics: Our commitment to safety and health is embodied in the design of machines with high ergonomics in order to improve the productivity of machine operators, thus minimizing their fatigue and avoiding accidents.

- Bending: All oven chamber with bending laminating performance offers a 500mm internal height.

- Environmentally friendly energy savings:Thanks to the consistency and reliability of our fast cycles, and the control and versatility of our software, it is possible to automate and leave the oven unattended during some phases of the process. This makes it possible, for example, to program the oven at a specific time of the night and without the presence of operators, in order to take advantage of the hours with the lowest electricity consumption costs the hours of lower electricity consumption cost and in a more efficient way.

- Vacuum bag with Ω letter design closure: The vacuum bag is manufactured with a pioneer perimeter closure with Ω letter- shaped design which allows a safe and effective closure that in addition to ensuring a tight seal, offers the user an easy and quick operation of closing and opening the bag.

- Free distorsion glass with no excess EVA on the edges: Our original high-performance vacuum bags contribute to a final product without excess EVA on the edges, saving time and additional operator costs for edge cleaning. The high elongation of the bags helps to reduce pressure and stress on the edges of the glass, avoiding bending effects and improving optical quality compared to traditional bags.

-

Ready for Industry 4.0 The LAM-PRO series (DUO & TOP) incorporates as standard the PUJOL e-Connect system which allows to obtain remotely and securely the traceability of the process, as well as to perform tele-assistance and production control services.

The main advantages of the Pujol 100 PVB + system are:

- Allows the lamination of PVB, EVA, and ionoplastics (SGP).

- Humidity and temperature control are not required for either storage or treatment.

- Fixed energy costs, independent of production volume.

- Reduced costs due to greater energy efficiency compared to traditional autoclave systems.

- Maximum precision and reliability.

- Lower raw material costs, as fewer film layers are required than in tempered PVB glass.

- Does not require a pre-lamination line.

- Requires less plant space.

- Minimal operator effort.

- High production rates.

- Industry 4.0 ready.

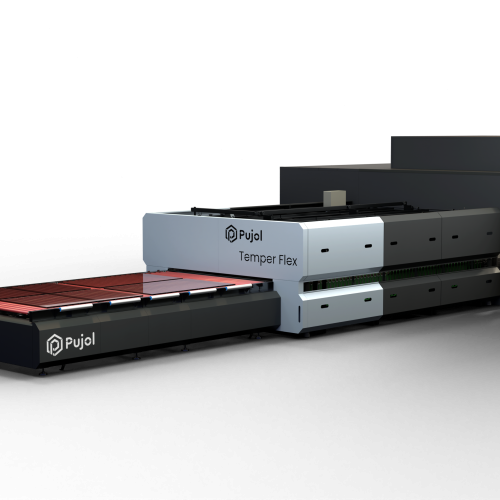

Temper Flex is a high value-added product designed to provide real answers to the needs of professionals based on 5 main axes:

1. High flexibility & lower consumption.

• Temper Flex can work at a double range of installed power and at a double speed (“ECO” or “PRO”).

• Able to process any type and thickness of glass.

• High flexibility on the tempering any kind of new high performance technical products.

2. High quality of the finished product.

Better planimetry and anisotropy in the glass, due to:

• Reduction of the diameter and pitch between rollers

• Better heat uniformity

• Exhaustive regulation of the fan motor speed and

advanced cooling control

• Advanced aerodynamic design of tempering nozzles.

• Production optimization software.

3. Greater savings and higher profitability per sqm of produced glass.

Greater energy efficiency thanks to:

• Elimination of steel protective soler of resistors

• Superior resistors designed by high-performance

matrix panels

• Use of the latest generation of high-tech super -insulating

materials.

• Continuous convection system.

• Software to control the required transformer power

4. Low maintenance costs.

• Long durability of the resistors with an average useful life of more than 10 years. 5-year Pujol warranty.

• Complete maintenance manual.

• Integral furnace design for fast and reactive maintenance.

5. Fast return on investment.

Glass treated using Hornos Pujol’s chemical tempering system offers significant advantages over heat-treated glass:

- These include: absolute transparency without the waves that cause optical distortions or anisotropy appearing in the glass after its installation.

- Greater safety owing to the substantial increase in the mechanical properties of the material.

- Reduced structural or hardware costs: higher quality or performance due to the reduced thickness of the glass, but also due to its lightness.

- This reduces the cost of laminated glass due to its perfect planimetry. Minimises the number of layers to be laid, as well as the thickness of glass to be used.

- High flexural strength. Owing to its improved mechanical properties, it is able to better absorb the stresses produced by permanent and variable loads that are placed on it.

- Highly scratch resistant: the chemical change produced in the glass thanks to Hornos Industriales Pujol’s Pujol-TQ System composite provides it with greater hardness. This makes it much more difficult to scratch this glass.

HST-L

HST-L is an oven designed by Hornos Pujol for glass lamination and heat soak testing.

Heat soak testing involves an accelerated ageing of the glass that indicates the presence of nickel sulphide in its composition. It is the only process certified worldwide to meet European Standard EN 14179-1 09/2005.

The main advantages of the HST-L are:

- Vertical HST treatment.

- Prevents spontaneous breakage of tempered glass due to nickel sulphide impurities.

- Horizontal lamination with Evalam in a silicone bag.

- Vertical lamination with Evalam in a single-use bag.

- ‘V’ shaped vertical convection systems.

- Superb temperature uniformity in the glass.

- Software offering quality control and traceability of the process.

- Single door lock.

- Multi-chamber option.

- Process and quality control: Pujol e-Connect

Click HERE for more information.

HST-V

HST-L is an oven designed by Hornos Pujol for glass lamination and heat soak testing.

Heat soak testing involves an accelerated ageing of the glass that indicates the presence of nickel sulphide in its composition. It is the only process certified worldwide to meet European Standard EN 14179-1 09/2005.

The main advantages of the HST-L are:

- Superb temperature uniformity in the glass.

- Software offering quality control and traceability of the process.

- Single door lock.

- Multi-chamber option.

- Process and quality control: Pujol e-Connect

Click HERE for more information.

HST spacers

These allow hot air to circulate during the heat soak testing process, and can be used when working with different glass formats. Made with high temperature resistant material, which ensures the durability of the product.

Automatic line

Complete high production line for the automation of EVA and/or PVB laminated glass production. This reduces production costs and increases laminated glass quality through the automatic alignment of the glass without taping or effort on the part of the operator. By automating this process, less additional machinery is required and directly lowers the cost.

This type of plant is fully adapted to customer needs. Plant designs can be adjusted to suit the space according to factory layout.

This increases production of laminated glass and generates cost savings.

Semi-automatic Line

This is a manually moving and automatically adjusted line which improves the quality of the laminated glass owing to greater precision in the alignment of the two or three sheets of glass to be assembled.

The semi-automatic production line was designed to help the operator achieve accurate centring of the glass layers, thereby speeding up and facilitating this procedure.

The semi-automatic line consists of the following elements:

- 50x28 elevating table (optional) which inserts and removes trays containing glass sheets from the different oven levels.

- Centring table that uses conveyor bearing which help the operator position the glass to the centred position.

- Assembly tables that contain conical bearings.

- Mobile handling unit with a mobile structure on a guide-rail to facilitate manual movement. It is also equipped with an elevating device and suction cups to transport the glass.

- Manual cutter (3 positions). EVA roll holder (up to three rolls) which also allows manual cutting of EVA once it is placed on top of the glass.

- Light overhead crane. Structure with a handling unit to move the glass.

Manual line

This is a manual production line with easier placement of both sheets of glass and film cutting for perfect assembly.

It is manually adjustable, which means that some intervention is required on the part of the operator, although it facilitates the EVA laminating process. This means greater cost savings and improved quality of finished product.

Designed by the Hornos Pujol engineering team, this plant can fully adapt to the needs of the glass processor. Plant designs can be adjusted to suit the space according to factory layout.

White rooms

This room is fast becoming a necessity among professional glass processors. Its characteristics ensure hygienic conditions which in turn maximise the quality of the final laminated composite. A white room guarantees that the glass will not come into contact with dust after exiting the washing machine, which minimises the risk of inclusions.

This custom-built structure considers the characteristics of the manufacturing area and the placement of its machinery. This optimises available space and investment.

Other advantages of our washing machines:

- Perfect washing of layered laminated glass.

- Entry and exit lengths designed for comfortable operation.

- Optimisation of working height.

- Reverse movement system.

- Pre-wash-wash-dry function.

- Quick cleaning.

- Automatic glass thickness sensor.

- Reverse osmosis water demineralizer.

- Easy to maintain and inspect.

- European-made.

Electric roll holder with guided cutter

Climate box

Electric cutter

Vacuum system with silicone bags

Backlit horizontal assembly table with holder and electric cutter

Glass + EVA assembly set includes:

- Evalam 1P or 3P holder / support roll(s) with electric disc cutter.

- Backlit assembly table with bearings.

- Equipped with electrical sockets for auxiliary equipment.

- Available in two sizes.

Electric roll holder with guided cutter

Electric 1P or 3P EVA holder / support roll(s) with electric disc cutter.

Climate box

- This climate box was designed by Hornos Pujol for the conditioned storage of special PVB films for laminating ovens using vacuum technology.

- With this design, rolls of PVB film can be loaded effortlessly through the hinged doors at the rear.

- It includes machinery with a disc cutter for easy cutting of the PVB film.

- Equipped with humidity and temperature control systems that guarantee optimal storage conditions.

Electric cutter

Electric EVA cutter to make cutting easy for lamination workers.

Vacuum system with silicone bags

Vacuum system with silicone closure

Silicone bag that withstands laminating temperatures. Its main function is to hold the sheets of glass during lamination; it features an omega (Ω) shaped silicone closure to ensure quick, simple and effective closure of the vacuum bag.

Teflon mesh

Graph-ruled Teflon blanket which allows air to flow freely outside the vacuum bag. Teflon’s non-stick properties means that any EVA leaks appearing during the laminating process will be very easy to clean.