Guardianstraße 4,

Bitterfeld-Wolfen 06766

Germany

Folienwerk Wolfen GmbH

Find us on:

Folienwerk Wolfen GmbH is an innovative film manufacturer with 110 years of rich tradition, specialized expertise, insight & solutions for your glass needs.

evguard®: EVA interlayer for laminated safety, security & architectural glass

A rich tradition

With more than 30 years of experience in the co-extrusion of eco-friendly plastic materials such as PET, PLA, BIO-PET and other specialities, Folienwerk Wolfen drives the industry with sustainable plastic solutions. Originating from the ORWO film plant, the company has a rich tradition and specialised know-how. As one of the first processors of plastics, the properties of various polymers were combined in one film using multi-layer technology. Our core value is providing solutions that encourage the evolution of society by using technologies, products and services. We relentlessly strive to be a company that supports the society of the future, by utilizing our diversity to create value for society's needs.

Specialised know-how

Today we produce individual 'made in Germany' films which are efficient and reliable. We have a global presence pioneering high quality EVA film processing, and are independently tested, approved and certified to most major standards worldwide. Our specialised knowledge ensures we start with quality first. Using high value raw materials we designed an innovative product, which is not only tailored to the high demands of architectural glazing, but is also multifunctional, extensively tested and highly adaptable to varying conditions. Our focus on quality, research and service ensures we deliver to your needs.

Future adaptive innovation

Innovation is the result of a process that brings together various novel ideas in such a way that they affect society. Why should there be limitations to artistic creativity within design and architecture? With evguard® we can offer you a product to realize the most innovative

Our in-house research & development, and GUARD hallmark, ensures we produce, test and deliver sustainable quality now and continue to adapt to the future at the forefront of glass film innovation - giving you a high quality product that saves you money in the long run via being durable, flexible & future-proof. We offer tailor-made sizes for your individual needs with various graduations and colors - evguard® laminating film in thickness (0.2mm to 1.14mm), width (800mm to 2400mm) and evguard® MPE thickness (0.2mm to 0.6mm), width (1000mm to 1250mm) - in order to decrease waste ratio and overall cost.

A masterpiece of ongoing research and development

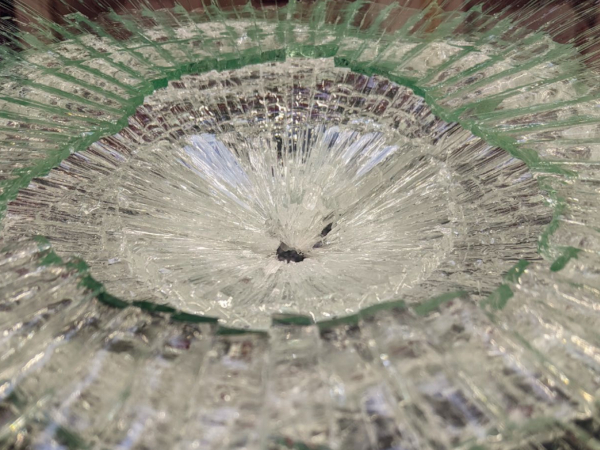

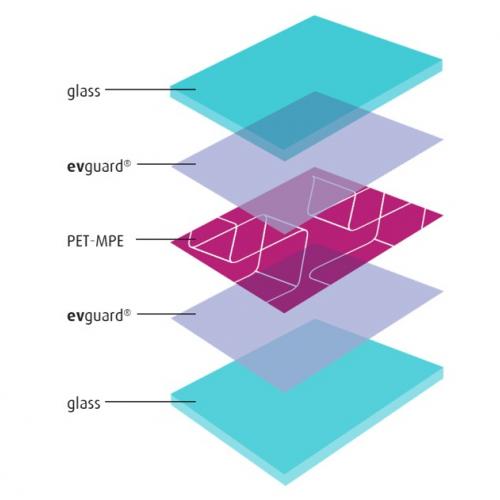

evguard® laminating film is an ethylene-vinyl-acetate (EVA) based thermoset interlayer for the manufacturing of laminated safety glass. Through processing, it forms a highly cross-linked three-dimensional composite interlayer that provides the strength for laminated safety, security and architectural glass.

evguard® laminating film is purposefully designed (and fully certified) for numerous glass building facades and extreme heavy impact applications worldwide, including external facades, overhead glazing and balustrades. It has passed all stringent standards to ensure long term stability and durability in these areas.

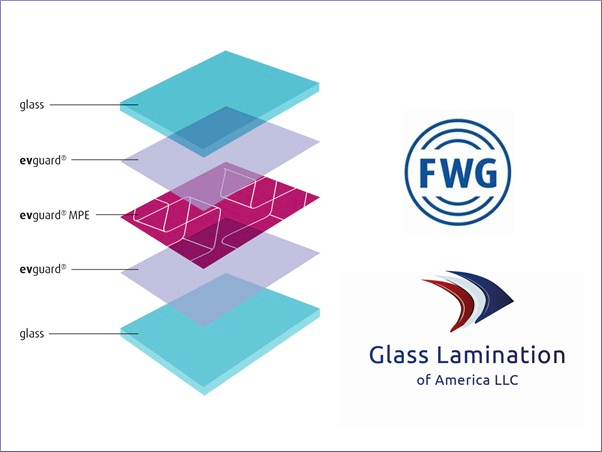

Folienwerk Wolfen also provides evguard® MPE, a „Modified Co-Polyester“, that brings significant improvement in terms of strength, stability, durability, shear modulus and printability. evguard® MPE is a special high performance multi-layer polyester film for heavy impacts and printed laminated safety glass applications.

Quality - so much more in just one film

evguard® laminating film is produced from the highest quality ingredients enabling us to in-house manufacture a multipurpose, multifunctional film which offers impact, weathering, high sound reduction, high shear strength, resistance to wide temperature range, a very well designed melting viscosity (for use in premium, sensitive inserts such as stone lamination, LCD, etc.) with high-processability in both vacuum & autoclave, plus more. With the product - DESIGNED, DEVELOPED and MADE in Germany - and with the use of European raw materials, we del

Safety – intensive testing for safe end product

We always conduct intensive testing and understand our social responsibility to develop a safe end product, which is made possible through our high quality European-made ingredients & additives (raw materials used to produce the evguard® laminating film range).

Consistency – quality maintained throughout

We deliver a consistent, durable film that can last. evguard® laminating film enjoys same strict quality procedures, ensuring the same quality and cleanliness, distributed by our highly knowledgeable European suppliers. We provide full traceability for every single roll back to particular raw material via our ERP System.

Certification – fully certified worldwide

We have certification for all climatic conditions worldwide, including DIBt, impact, weathering, sound reduction, salt water, hurricane testing & balustrade testing, as well as for the highest hygiene standards (due to our experience manufacturing products for the medical, pharmaceutical, automotive and food applications).

Strong, efficient global network of distributors to make it easy.

Our mission is to continue to innovate and deliver quality, safe, flexible, energy efficient, future proof, and interesting glass.

Our large network of distributors make it possible for us to bring this quality to you, providing expert technical support to customers worldwide.

We are on the same mission in making world class glass that inspires and guards you.

Products

With its outstanding properties and performances, amongst only few others, evguard® is a high-end, premium quality laminating film for the glass industry – fully certified worldwide.

It has been tested to to the toughest conditions, far beyond the standard certification.

evguard® laminating film already fulfills the highest classification 1 (B) 1 of the pendulum impact test DIN EN 12600:2002 (DEKRA/Certificate No.201330010) with a composite structure of FL 44.1 (float glass, 2x 4.0mm (+/- 0.2mm) with a layer of evguard® laminating film, thickness 0.38mm).

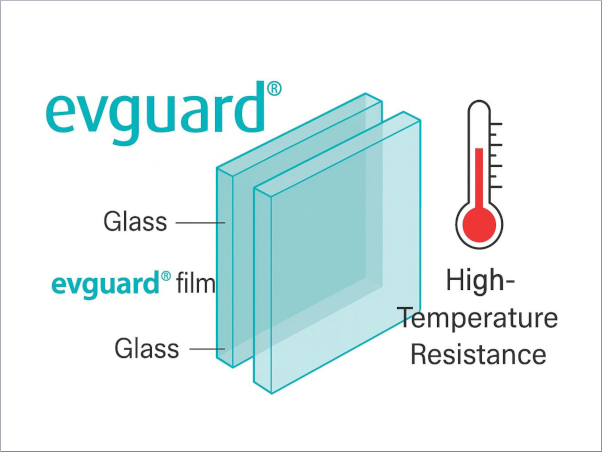

evguard® passes DIN EN ISO 12543-4 for behaviour at high temperature (Bake Test/ IFT Rosenheim). To investigate the behaviour of glass laminates at temperatures beyond the international standard test DIN EN ISO 12543-4, further tests were carried out. To prove the behaviour of laminated glasses with evguard® laminating film, laminated glass samples were exposed stepwise up to a temperature of 240°C. The glass laminates passed the test up to at least 200°C without any delamination effects or visual changes. Also at a temperature of 240°C, no delamination was detected, only a slight yellowing was observed.

In accordance with the norm DIN EN ISO 12543-4, the artificial aging by UV irradiation was carried out by means of a xenon-arc solar simulation spectrum with a power of 50 W / m² in total UV wavelength. The examined samples have been continuously irradiated for 3,000 hours. In this case, a control measurement of the haze values and the light transmission was carried out for every 500 h. The artificial aging by UV radiation was carried out by Friedmann & Kirchner testing institute (Germany) on laminated glass samples made from a series of different laminates. Both the LSG made with evguard® laminating film and evguard® laminating film + evguard® MPE passed the test successfully. No visual change of the quality of the laminate was observed.

evguard® passes GOST Standard 30826/32996-2014 at minus 70 deg C.

evguard® passes continuous salt spray for 3,000 hours in a salt spray test according to ASTM B117/ISO 9227.

In the test chamber of the salt spray cabinet, which is heated to 35 ± 1°C, a solution of 5 ± 1 percent by mass of sodium chloride with a pH 6.5 – 7.2 is atomized continuously. As a result of spraying this solution, the relative humidity in the test cabinet is more than 95 %. In time, all panels show more or less iridizing colors due to the aggressive attack of salt spray on the top coating on the glass. None of the samples show delamination.

evguard® laminating film provides low deflection and high shear modulus. Thus, for architectural calculations, overall laminate thicknesses can be reduced significantly resulting in savings. evguard® laminating film offers safety properties in a broad temperature range, not only at room temperature but also at temperatures above 50 °C. These properties bring new possibilities in open edge applications since there is no need for frames anymore.

evguard® laminating film is less sensitive to moisture compared to other interlayer films like ionomers or PVB. This offers a great advantage in resistance of the laminate against weathering conditions and durability of the final product. evguard® laminating film is suitable for open edge applications and does not require a strict moisture control during transportation, storage and use. (DIN EN ISO 62)

Sound insulation glass made with evguard® laminating film with a 44.2 construction achieves a sound insulation rate of at least 37 dB without additional sound insulating layers. (ISO 10140-2/MFPA Leipzig)

Because the glass layers form a solid composite once they are laminated with evguard® laminating film, and evguard® nonetheless remains highly elastic, this type of laminated glass is ideally suited for use as protection from break-ins or falls, or even for much stronger loads by adding our evguard® MPE - Special high performance multi-layer polyester insert for heavy impact and printed laminated safety glass applications. With the 55.4.MPE(800) construction it passes Florida Building code TAS 201-94 (Large Missile) and TAS 203-94@ ±120 psf (Cycling).

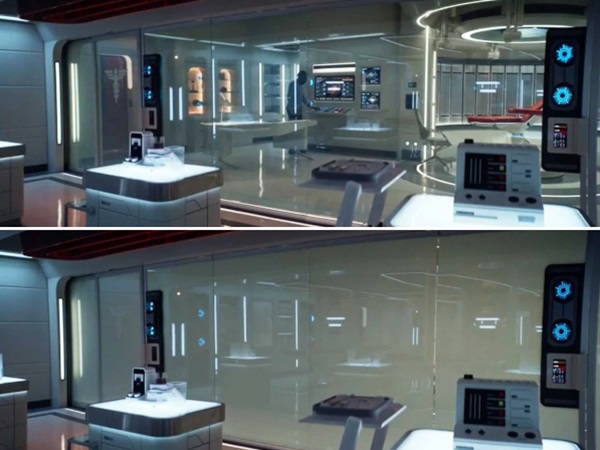

Beautiful, spectacular designs achieved by laminating glass with EVA film: In interior architecture, evguard® is frequently combined with inserts to achieve striking effects. Privacy vista glass - beautifully customisable wind and privacy protection, stunning glass prints - from showers to kitchen wall ties, from door to glass wall dividers, switchable glass windows - from windows to walk-in showers, from doors to glass wall dividers, curved glass designs, innovative applications - heavy impact & durability applications like solar cell roadways and more.