Via Trieste, 13

Tribiano 20067 MI

Italy

Fenzi Spa

Find us on:

Fenzi Group is a global leader in chemical solutions for the glass industry, proudly operating since 1941. Headquarters in Milan and guided by its founding family, Fenzi has built a reputation for excellence, innovation, and sustainability across more than 80 countries.

With 18 manufacturing plants and sales offices worldwide, Fenzi offers the most comprehensive portfolio of technologies for mirror production, insulating glass, decorative and automotive glass, as well as flat and hollow glass applications. As the only full-solution provider in its field, Fenzi sets the benchmark for quality and performance in glass processing.

Our Core Divisions and Technologies

Fenzi S.p.A.

Fenzi offers high-performance products such as sealants and spacers for production of Insulating Glass Units. The company’s diverse product portfolio also includes mirror-backing paints and coatings under the Duralux and Luxver brands, providing eco-friendly, durable finishes for both standard and solar mirrors.

Alu-Pro & Rolltech

Renowned manufacturers of traditional and warm-edge spacers, with production facilities in Denmark, Poland, and the United States.

Fenzi Advanced Glass Technologies (AGT)

Innovators in advanced materials and conductive inks for automotive and industrial glass, including enamels, silver pastes, and high-performance coatings.

Tecglass

Specialists in digital printing technologies for glass, offering cutting-edge machines, inks, and tools for ceramic and architectural applications.

Thermoseal

The UK’s leading manufacturer and distributor of IG components, known for its extensive product range and high-performance warm-edge spacers like Thermobar and Thermoflex.

Products

If, for some strange reason, you have not yet had the chance to use them, you have certainly already seen them, starting with the many objects in your home: most of the mirrors in the world are made using Fenzi Duralux paints.

The Duralux range includes several versions, developed to best meet the most diverse needs of all mirror manufacturers across the world. You will find the perfect Duralux product to meet your needs, from the most traditional to sophisticated copper-free and zero-lead technologies.

The product range is even more complete, now that the Luxver glass silvering array of products is available alongside Duralux. Already the product of choice for some of the leading glass companies, with Duralux and Luxver, Fenzi offers a unique set of products to cover the entire mirror production cycle.

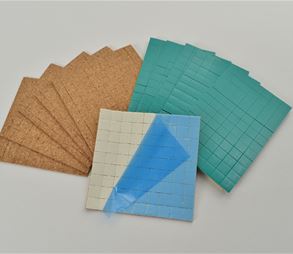

Thermoplastic and termosetting mirror-backing paints, available in copper-free formulations

Although each product has become a classic in its field of application, Fenzi research never stops; it strives to continually improve performance, and also to ensure practicality and ease-of-use, day after day.

Along with several polysulphide, butyl, hot-melt and polyurethane sealants, Fenzi also supplies the manufacturers of IG units with spacer profiles in aluminum, steel, and stainless steel made at Alu-Pro and Rolltech facilities and sold around the world by the Glass Alliance network. Completing the product range are molecular sieves specifically engineered to absorb moisture vapor.

Two-component polysulphide sealant

One-part thermoplastic solvent free polyisobutylene based spacer

One component hot melt sealant

Two-component polyurethane sealant

Each of these numerous applications call for the highest levels of performance and the ability to ensure the utmost freedom of expression. Fenzi decorative glass paints are very popular in many markets, precisely because of their exemplary features. They are manufactured and sold in two different types: Tempver glass enamels for screen-printing, enameling and satin-finishing glass, and organic Decover paints for cold application to achieve maximum sheen and color. The Decover range includes the Glasslux, Sandolux, and Pearlux organic solvent paints, and the Aquaglass water-based paints.

Decorative enamels for screen-printing, enamelling and satin-finishing of glass.

On one hand, the coating must be able to stand up under conditions of enormous stress; on the other, they need to be as eco-friendly as possible. Fenzi met this big challenge by creating a dedicated division, Fenzi Solar Coatings, specialized in research applied to the innovative technologies for solar energy. The result is Duralux Solar Coatings, a range of solar mirror coatings engineered to meet the highest standards of durability and resistance required by the most advanced solar heating systems. Duralux Solar Coatings were so innovative in the chemical world the industry had to develop new reference parameters in order to test their performance.

A vast line of profiles for artistic (leaded) glass and a huge variety of architectural paints complete the range of products developed by the Group.

But that is not all. Fenzi can also provide a full assortment of flat glass processing accessories, like polishing wheels, glass cutters, small parts, hardware and machinery to support all phases of processing.

The Fenzi Buildcoat paints finish and protect architectural components for external use.

PROFILES FOR 'LEADED' ARTISTIC GLASS