This paper was first presented at GPD 2025.

Link to the full GPD 2025 conference book: GPD_2025_ConferenceProceedingsBook.pdf

Authors: Juan Pablo Martínez, Diana Lohrer

ES Windows LLC, United States

Abstract

Spontaneous breakage of tempered glass due to nickel sulfide (NiS) inclusions presents a serious safety concern in large-scale architectural applications. This phenomenon arises when nickel reacts with sulfur during the glass manufacturing process, forming inclusions that undergo phase changes over time, inducing internal stresses that can cause sudden fractures without prior warning. These breakages typically occur without any visible signs, making them a hidden risk to the structural integrity and safety of buildings. This paper examines the origin of NiS inclusions, their formation mechanisms during production, and their potential long-term effects on glass performance. Although these inclusions are often undetectable through standard visual inspection, their consequences can be catastrophic, especially in cases where glass plays a structural or safety-critical role. We explore current methods used to identify and mitigate these risks, with a particular focus on the Heat Soak Test (HST), an industry-recognized technique that exposes susceptible glass units to thermal cycling in order to trigger premature failure before installation. Additionally, we discuss preventive strategies such as improving raw material purity, refining furnace environments, and enhancing quality control practices to reduce the likelihood of nickel contamination. Beyond risk management, the paper also proposes forward-looking solutions to enhance glass reliability in demanding environments. These include considering alternative products like heat-strengthened or laminated glass, which offer increased resistance to spontaneous breakage while preserving transparency and design flexibility. Ultimately, this study seeks to contribute to a broader industry conversation around tempered glass safety, encouraging innovation and proactive measures to ensure that architectural glazing continues to meet the highest performance and safety standards.

Article Information

- Published by Glass Performance Days, on behalf of the author(s)

- Published as part of the Glass Performance Days Conference Proceedings, June 2025

- Editors: Jan Belis, Christian Louter & Marko Mökkönen

- This work is licensed under a Creative Commons Attribution 4.0 International (CC BY 4.0) license.

- Copyright © 2025 with the author(s)

1.Introduction

Tempered glass is widely utilized in construction, automotive, and architectural applications due to its enhanced strength and durability. However, an inherent risk associated with this material is the presence of nickel sulfide (NiS) inclusions, which can lead to spontaneous glass breakage. This phenomenon occurs without warning and poses significant safety concerns, particularly in large glass installations where structural integrity is critical.

Nickel sulfide inclusions have the potential to cause unexpected fractures, which can compromise safety in high-traffic environments. While manufacturers employ various methods to detect and mitigate this issue, a comprehensive understanding of NiS inclusions, their formation, detection techniques, and preventive measures is essential for improving glass safety.

Nickel sulfide (NiS) is not an intentional component of tempered glass but rather a contaminant formed when nickel and sulfur react during the glass manufacturing process. The primary sources of nickel contamination include:

- Raw Material Impurities: Nickel-bearing minerals in silica sand, soda ash, or recycled glass (cullet).

- Production Equipment Wear: Nichrome wire from heating elements, stainless steel particles from conveyor systems and cutting tools, and welding spatter from furnace maintenance.

- Environmental Contamination: Nickel-containing dust from industrial operations and combustion residues from furnace fuels.

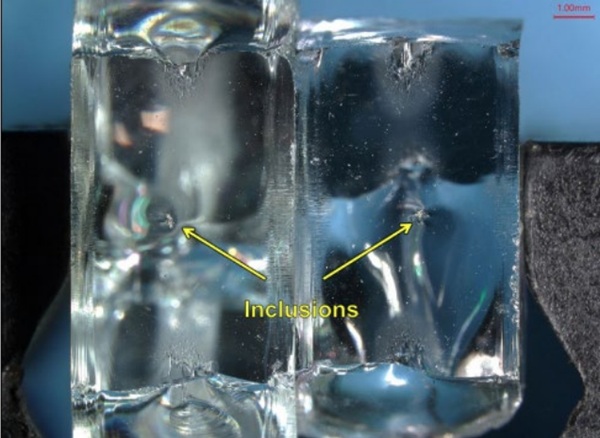

During the float glass production process, impurities introduced into the molten glass may remain as solid, opaque inclusions. While many of these are purely cosmetic defects, nickel sulfide inclusions are an exception, particularly in heat-treated glass. NiS inclusions originate when nickel-rich contaminants interact with sulfur from batch materials or furnace fuel. In annealed glass, NiS inclusions remain stable, but in tempered glass, they can undergo a phase transformation over time, potentially causing spontaneous breakage.

2. Risks of Nickel Sulfide Inclusions

Nickel sulfide inclusions pose multiple risks, primarily affecting the safety and reliability of tempered glass. Spontaneous Breakage NiS inclusions can induce internal stresses within tempered glass, leading to spontaneous failure. Unlike typical breakage caused by impact, NiS-induced failures occur without external force. This breakage is characterized by:

- Fracture origin at the glass center rather than edges.

- A distinctive “butterfly” or “figure-eight” pattern around the NiS inclusion.

- Breakage occurring months or even years after installation.

The internal stress buildup from NiS inclusions is exacerbated by temperature fluctuations and external pressure, increasing the unpredictability of failure.

One of the greatest challenges in managing NiS inclusions is their microscopic size, which makes them undetectable to the naked eye. Standard visual inspections cannot identify these inclusions, necessitating advanced detection technologies before installation.

3. Safety Risks in Large-Scale Installations

NiS inclusions pose particular risks in architectural glass installations such as:

- High-rise building facades

- Glass staircases and barriers

- Curtain wall systems

Spontaneous glass failure in these applications can result in severe safety hazards, structural damage, and costly repairs.

4. Financial and Legal Consequences of Spontaneous Breakage

The spontaneous breakage of tempered glass due to NiS inclusions carries significant financial and legal ramifications, including:

- Direct Financial Costs

- Replacement and repair expenses

- Property damage to surrounding structures

- Business disruptions in commercial environments

- Increased insurance premiums due to repeated claims

4.1. Legal Liabilities

- Personal injury lawsuits resulting from falling glass fragments

- Breach of contract claims in construction projects

- Product liability suits against manufacturers for supplying defective glass

- Reputational and Regulatory Consequences

- Loss of trust among clients and stakeholders

- Stricter building code requirements for heat-treated glass

- Potential fines for non-compliance with safety regulations

5. Methods for Detection

Traditional visual inspection methods are ineffective in detecting NiS inclusions, necessitating the use of advanced testing techniques. The two primary methods for detecting NiS inclusions are the Heat Soak Test (HST) and Thermal Imaging.

5.1. Heat Soak Test (HST):

The Heat Soak Test (HST) is the most widely used method for detecting NiS inclusions before glass installation. It adheres to the EN 14179-1 standard, which requires exposing tempered glass to elevated temperatures of 290°C ± 10°C and maintaining a holding phase temperature range of 260°C ± 10°C for a minimum of two hours. This process accelerates the phase transformation of NiS inclusions from the high-temperature α-phase to the expanded β-phase, inducing breakage inside the controlled chamber rather than during service (EN 14179-1, 2016).

Test duration

- 2-hour HST: Suitable for standard application.

Challenges of HST

- Size Limitations: HST is most effective for NiS inclusions larger than 50 μm. Smaller inclusions may not expand sufficiently to induce breakage (Jacob, 2001).

- Variability in Phase Transformation: The transition from α-NiS to β-NiS depends on temperature and time, and some inclusions may take longer than the test duration to expand (Haldimann, Luible & Overend, 2008).

- Residual Risk: HST eliminates approximately 90-95% of NiS-infected glass, leaving a 5-10% residual risk (Ensslen & König, 2010).

- False Negatives: Some NiS inclusions located in low-stress regions may survive HST but expand later in high-stress areas post-installation (Schneider & Schuler, 2015).

- Cost and Practicality: HST adds to production costs and processing time, and not all manufacturers implement it due to economic considerations.

Thermal Imaging

Thermal imaging is an advanced, non-destructive method for detecting internal stresses caused by NiS inclusions. It utilizes infrared (IR) cameras to detect temperature variations on the glass surface, which may indicate subsurface stress (Siebert, 2011).

Mechanism of Detection

- Infrared Radiation Detection: IR cameras capture heat radiation emitted from the glass surface.

- Temperature Variations: Areas with NiS inclusions display temperature anomalies due to altered heat conduction.

- Stress Mapping: By identifying stress regions, thermal imaging helps locate potential NiS inclusions that may not be visible otherwise.

Advantages

- Non-destructive: No need to cut or damage glass.

- Rapid Testing: Large glass panels can be scanned efficiently.

- Effective Stress Identification: Captures microscopic stress variations, potentially indicating hidden NiS inclusions.

Limitations

- Surface-Level Detection: Less effective for deeply embedded inclusions.

- Expertise Required: Interpreting thermograms accurately requires skilled operators.

6. Preventive Strategies and Alternatives

To reduce the risk of nickel sulfide (NiS) inclusions and spontaneous breakage in tempered glass, manufacturers are adopting advanced production technologies and quality control systems designed to detect and eliminate nickel contaminants from the earliest stages of the process. Enhanced raw material screening and production upgrades play a crucial role in ensuring high-quality glass.

7. Optimizing Raw Material Purity

Using high-purity raw materials significantly lowers the chance of nickel contamination. This includes sourcing premium-grade silica sand, soda ash, and limestone with minimal trace elements of nickel and sulfur. Collaborating with certified suppliers who uphold rigorous quality standards is essential.

Quality control procedures—such as monitoring cullet moisture, granulometry, and contamination levels—combined with well-equipped laboratories, further enhance raw material integrity.

8. Integrated Solutions from Raw Materials to Final Inspection

A holistic, end-to-end strategy is critical for mitigating nickel contamination throughout the entire glass manufacturing process:

8.1. Advanced Screening and Pre-Melting Technologies

Nickel contamination typically stems from raw materials such as silica sand, soda ash, dolomite, and cullet (recycled glass). Key detection and removal methods include:

- X-ray Fluorescence (XRF) Spectroscopy: Provides real-time elemental analysis to detect nickel and other metallic impurities before they reach the furnace (ASTM E1621-13).

- Inductively Coupled Plasma (ICP) Spectroscopy: Delivers precise quantification of nickel-bearing minerals in raw materials.

- Automated Magnetic Separation: Removes nickel-rich fragments—such as stainless steel, nichrome wire, and welding debris—especially from cullet streams.

8.2. Nickel-Resistant Equipment and Real-Time Monitoring

Upgraded equipment and process monitoring help reduce contamination risks during the melting phase:

- Nickel-Free Furnace Components: Replacing nichrome elements with ceramic wear plates, coated linings, and non-nickel alloys limits direct contact-based contamination.

- Automated Cleaning Systems: High-efficiency vacuum and filtration systems remove nickel-laden dust from critical areas.

- LIBS Technology (Laser-Induced Breakdown Spectroscopy): Enables real-time detection of nickel compounds during melting, allowing for immediate process adjustments.

8.3. Inline Quality Control and Defect Detection

To prevent contaminated glass from advancing to tempering, advanced inspection tools are implemented:

- High-Resolution Optical Systems: Use infrared and UV imaging enhanced by machine learning to identify solid inclusions such as NiS.

- Ultrasonic and Acoustic Emission Testing: Experimental methods that detect internal defects prior to heat treatment.

- AI-Based Defect Mapping and Sorting: Automates the identification and rejection of defective glass sheets, improving overall reliability and safety.

8.4. Additional Preventive Measures and Product Alternatives

In addition to technical solutions, process controls play a vital role:

- Strict Supplier Controls: Certification programs and regular batch testing ensure material purity.

- Closed-Loop Material Handling: Segregating raw materials from recycled glass minimizes crosscontamination.

- Advanced Cullet Management: Sorting and pre-melting filtration effectively eliminate nickel-bearing debris.

- 4-hour HST recommended for high-risk applications such as glass facades and structural glass, ensuring more thorough detection of inclusions.

When risk mitigation is critical, heat-strengthened and laminated glass offer alternative solutions with reduced susceptibility to spontaneous breakage, while providing distinct structural and safety benefits.

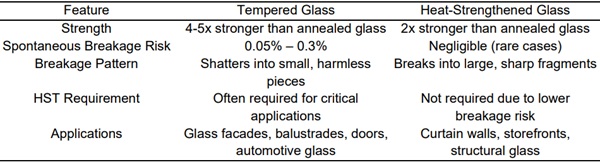

8.5. Heat-Strengthened Glass

Heat-strengthened glass is produced using a process similar to tempered glass but with a lower cooling rate, resulting in less internal stress. This makes it twice as strong as annealed glass but not as strong as fully tempered glass.

Comparison with Tempered Glass:

Table 1: Difference Heat Strength Glass and Tempered Glass.

Pros of Heat-Strengthened Glass

- Lower risk of spontaneous breakage due to fewer internal stresses.

- More resistant to thermal stress than tempered glass.

- Does not require HST, reducing processing costs.

- Suitable for structural glazing, where strength and minimal risk of breakage are priorities.

Cons of Heat-Strengthened Glass

- Does not meet safety glazing standards in some cases (e.g., automotive applications).

- Less impact-resistant than tempered glass.

- Breaks into sharp pieces, posing a potential safety hazard.

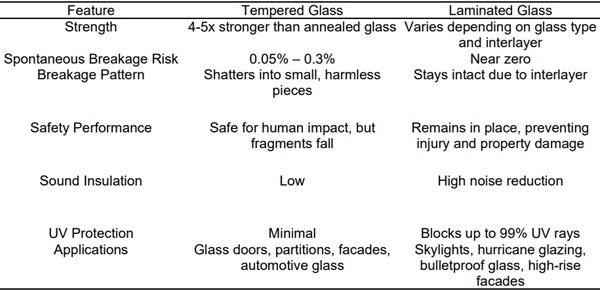

8.6. Laminated Glass

Laminated glass consists of two or more layers of glass bonded with an interlayer (typically polyvinyl butyral (PVB) or ionoplast (SGP)). This interlayer holds the glass fragments together upon breakage, preventing dangerous shards from falling.

Comparison with Tempered Glass:

Table 2: Difference Laminated Glass with Tempered Glass.

Pros of Laminated Glass

- Eliminates spontaneous breakage risk, as broken glass stays intact.

- Meets all safety glazing standards, even in high-impact zones.

- Enhances security, preventing forced entry.

- Provides sound insulation, reducing noise pollution.

- Blocks UV rays, protecting interiors from fading.

Cons of Laminated Glass

- More expensive than tempered and heat-strengthened glass.

- Heavier, requiring stronger structural support.

- Can develop edge defects if exposed to prolonged moisture

Laminated glass is the best alternative for applications requiring maximum safety and reliability, such as hurricane-resistant windows, bulletproof glazing, and overhead skylights.

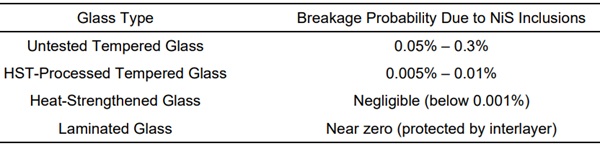

9. Industry Breakdown of Breakage Risks

According to industry data, the risk of spontaneous breakage varies by glass type and application:

Table 3: Industry Breakdown Breakage Risk per type of Glass.

Industry Data on Glass Breakage Risks:

- In high-rise buildings, spontaneous breakage of tempered glass has caused multiple incidents worldwide, leading to stricter building codes and increased use of laminated glass.

- Automotive glass primarily uses laminated glass for windshields, while tempered glass remains in use for side windows due to its ability to shatter safely.

- Façade glass is increasingly shifting toward heat-strengthened laminated glass to reduce breakage risks and improve impact resistance.

10. Conclusions

Nickel sulfide (NiS) inclusions pose a significant, though often undetectable, risk in tempered glass, potentially leading to spontaneous breakage. To mitigate this, the glass industry must adopt stringent manufacturing controls, improve detection technologies such as heat soak testing (HST) and thermal imaging, and consider alternative glass solutions when appropriate. Addressing NiS inclusions is essential to ensure the long-term safety, performance, and reliability of tempered glass in architectural and other high-demand applications.

Advancements in nickel detection, furnace design, and inline quality control systems are playing a crucial role in reducing NiS inclusions in float glass production. Automated screening, real-time monitoring, and AI-driven defect detection are becoming essential tools for manufacturers striving to improve glass quality and minimize breakage risks. However, despite these advancements, there are no universally adopted industry standards specifically focused on nickel detection in raw glass. Organizations like ASTM International provide general guidelines on permissible blemishes, including NiS inclusions, but do not mandate specific detection technologies due to the challenges of identifying microscopic contaminants.

While sophisticated analytical techniques exist for detecting nickel contamination, their widespread adoption in large-scale glass production remains constrained by cost, speed, and technological limitations. As a result, the industry continues to rely on preventive measures such as strict raw material selection, process controls, and post-production testing to minimize the presence of NiS inclusions. Ongoing research and emerging technologies may eventually lead to more effective and cost-efficient detection methods.

The choice between tempered, heat-strengthened, and laminated glass depends on the specific safety, durability, and performance requirements of an application:

Heat-strengthened glass is best suited for façades and structural glazing where spontaneous breakage must be minimized but full safety glazing is not required.

Laminated glass offers the highest level of safety, UV protection, and noise insulation, making it ideal for skylights, hurricane-resistant glazing, and high-rise exteriors.

While tempered glass remains a widely used industry standard, increasing concerns over spontaneous breakage are driving a shift toward safer alternatives, particularly in critical infrastructure and public spaces. As technology and industry practices evolve, proactive risk mitigation strategies will be essential to maintaining the safety and reliability of glass in modern architecture.

References

Mitchell, J. A., Thomson, M., & Coyne, R. P. (2017). A guide to citation. My Publisher.

Williams, S. T. (Ed.). (2015). Referencing: A guide to citation rules (3rd ed.). My Publisher.

Mitchell, J. A. (2017). Citation: Why is it so important. Mendeley Journal, 67(2), 81–95.

https://doi.org/10.1007/s00339-007-4137-z

ASTM International. (2016). ASTM C1036-16: Standard specification for flat glass.

European Committee for Standardization. (n.d.). EN 14179-1: European standard for heat soaked thermally toughened glass.

Pilkington Glass. (n.d.). Technical bulletin on nickel sulfide inclusions.

Saflex. (n.d.). Interlayers for laminated glass: Technical data sheet.

Glass Research Association. (n.d.). Reports on NiS inclusion detection methods.

ASTM International. (2013). ASTM E1621-13: Standard guide for elemental analysis by X-ray fluorescence spectrometry.

Ensslen, F., & König, J. (2010). Effectiveness of heat soak testing for NiS inclusion detection. Glass Performance Journal.

Haldimann, M., Luible, A., & Overend, M. (2008). Structural use of glass. IABSE-AIPC-IVBH.

Jacob, L. (2001). The role of nickel sulfide in tempered glass breakages. Glass Research Journal.

Schneider, T., & Schuler, C. (2015). Thermal imaging for non-destructive evaluation of glass stresses. Glass

Science & Technology.

Siebert, G. (2011). Advancements in thermal imaging for stress analysis in glass. Infrared Technology Review.

Vitro Architectural Glass. (n.d.). Nickel sulfide and spontaneous breakage. https://glassed.vitroglazings.com

Giroux Glass. (n.d.). How does nickel sulfide inclusion cause spontaneous glass breakage?

https://www.girouxglass.com

Google Patents. (n.d.). Method for detecting nickel sulfide in glass. https://patents.google.com

Glass for Europe. (n.d.). Heat-strengthened glass vs. tempered glass: Key differences and applications.

https://www.glassforeurope.com

Vitro Architectural Glass. (n.d.). Laminated glass: Benefits, applications, and performance.

https://www.vitroglazings.com

Pilkington Glass. (n.d.). Heat-strengthened and laminated glass: Industry standards and safety considerations.

https://www.pilkington.com

ASTM International. (n.d.). Standard specification for heat-strengthened and laminated safety glass.

https://www.astm.org

Saint-Gobain Glass. (n.d.). Spontaneous breakage risks and prevention methods in tempered glass.

https://www.saint-gobain-glass.com

Guardian Glass. (n.d.). Industry insights on spontaneous breakage in high-rise facades.

https://www.guardianglass.com