Date: 16 September 2025

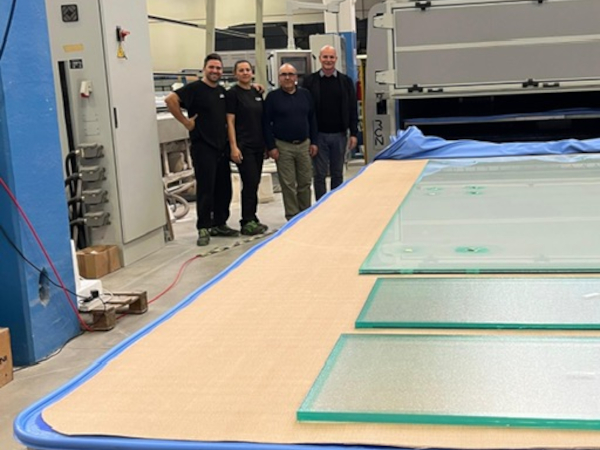

Since its founding TK has established itself as a highly reliable and innovative player in the global glass processing market. Their commitment to using the best Italian technology and European components ensures high quality, safety, and efficiency across their product range. With over 30 TK tempering plants installed globally, TK has demonstrated its reliable, battle-tested tempering technology and efficient energy solutions, distinguishing itself for much lower energy consumption compared to traditional tempering machineries.

The challenge: meeting global demand for high-quality tempered glass

The demand for high-quality tempered glass is consistently growing across various industries, including architecture, automotive, and appliance manufacturing. Tempered glass offers superior strength, safety, and thermal resistance compared to annealed glass. Glass manufacturers worldwide face the challenge of producing tempered glass efficiently, consistently, and to the highest quality standards, while also optimizing energy consumption and operational costs.

Thermal tempering significantly improves the properties of glass, offering a range of benefits over untreated (annealed) glass:

Increased strength and durability: this is the primary benefit. Thermally tempered glass is typically four to five times stronger than annealed glass of the same thickness. This enhanced strength makes it much more resistant to impact, mechanical stress, and wind loads.

Increased strength and durability: this is the primary benefit. Thermally tempered glass is typically four to five times stronger than annealed glass of the same thickness. This enhanced strength makes it much more resistant to impact, mechanical stress, and wind loads.- Enhanced safety: when tempered glass breaks, it shatters into small, relatively harmless, blunt-edged fragments instead of large, sharp, dangerous shards. This significantly reduces the risk of injury, making it ideal for applications where safety is a concern.

- Improved thermal shock resistance: tempered glass can withstand significant and rapid temperature changes without breaking. It can tolerate temperature variations of up to 200°C (392°F), whereas annealed glass can break with a temperature difference of around 30°C (86°F). This makes it suitable for applications exposed to high or fluctuating temperatures, such as oven doors, fireplace screens, and areas with direct sunlight.

- Versatility: thermally tempered glass is highly versatile and used in a wide range of applications

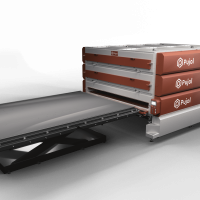

TK's Solution: advanced thermal tempering ovens

TK addresses these challenges with its range of advanced thermal tempering plants. These kilns are designed to meet diverse production requirements, from large-scale industrial operations to more specialized needs.

Key features include:

- Low energy consumption: TK temper offers high-performance, European-sourced materials that provide excellent thermal insulation and minimal heat loss, resulting in significantly reduced energy consumption.

- Hot air convection technology: TK Temper ovens utilize hot air convection directly in the heating chamber, ensuring uniform heating of the glass sheets. This precise temperature control is crucial for achieving consistent tempering quality and minimizing defects.

- Optimized heating and cooling: the plants incorporate a hot air pre-heating chamber and fused silica ceramic rollers for efficient heat transfer. The movement of ceramic rollers with double belts further contributes to smooth and consistent processing.

- Advanced process control: each individual heating zone within the oven has its own thermocouple connected to a control microprocessor, which is interfaced with a PLC. This allows for precise setting and modulation of set-point, PID parameters, alarms, and power percentage for each zone. All data is stored in recipes, enabling easy retrieval and ensuring repeatability of processes. The heating power is controlled by SCRs (Silicon Controlled Rectifiers) that modulate output based on temperature trends, optimizing energy usage.

- Global reach and support: TK has a significant global presence, with over 270 installed systems in over 60 countries. A key differentiator is their commitment to on-site technical assistance, including installation, maintenance, and comprehensive training for customer personnel. This hands-on approach minimizes complications and ensures optimal performance of their machinery worldwide.

- TKonnect 4.0: TK's commitment to innovation is exemplified by TKonnect 4.0, a remote system for real-time monitoring of oven production processes via smartphone or computer. This system provides a fully intuitive user interface and leverages the latest technology for data connection and production report downloads, enhancing operational efficiency and predictive maintenance.

Conclusion:

TK S.r.l. has established itself as a trusted partner for glass manufacturers worldwide by providing Italian innovative, high-performance tempering plants. Their focus on advanced technology, customized solutions, and comprehensive global support has enabled customers to enhance their production capabilities, improve product quality, and achieve greater operational efficiency in the competitive glass processing industry.

Contacts:

ask@tkitaly.com

+39 031 3574873

tkitaly.com

600450

600450

Add new comment