Author: Alessa Koskinen | Glaston

Source: www.glastory.net

In glass tempering, energy efficiency often depends on how well the process adapts to real-world production patterns. One common challenge is that many glass processors don’t always utilize the full loading length of the tempering line. In fact, studies show that up to 50% of loadings can be significantly shorter than the line’s maximum capacity. With traditional chillers, the same amount of energy is used regardless of the actual load length, resulting in increased energy consumption per square meter.

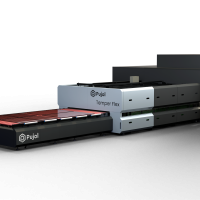

Glaston’s answer to this challenge is Adaptive Quench—a smart cooling solution that automatically adjusts the quenching section to match the actual glass loading length. When the loading is shorter than the maximum, the system reduces both the cooling and oscillation areas accordingly. This targeted cooling approach significantly lowers the energy required for quenching, without compromising glass quality.

In short, Glaston’s Adaptive Quench technology enables smarter energy use in short loading scenarios, helping glass processors cut costs and carbon footprint while maintaining high productivity.