Bergstraße 2

Ploessberg 95703

Germany

Horn Glass Industries

Find us on:

HORN Glass Industries AG, a German specialist in the design and supply of complete glass melting technology is a solution partner for the worldwide glass industry.

At its location in Plößberg, Germany, HORN Glass Industries AG plans and makes glass melting technology and turn-key projects for the float and container glass industry. The high-performance glass melting furnaces and turn-key projects go to glass manufacturers all over the world and serve the production of beverage bottles, food containers, drinking glasses, glass panes, glass tubes, glass fibers or special glass.

With more than 140 years of experience, HORN has been the specialist and expert in the field of the construction of glass melting furnaces for many years. However, since many years this has changed and HORN is now one of the industry leaders in the implementation of turn-key projects.

Subsidiary companies in China, Malaysia, India, Croatia, Ukraine, Brazil and the Czech Republic add value to the global customers. So, HORN offers customer proximity and short response time in the global market. Almost 90% of the products are exported from Plößberg in Upper Palatinate to more than 75 countries worldwide.

Products

High furnace capacity up to 1200 t/d, high quality glass for architecture or automotive purpose, low energy consumption, low emmission values.

GENERAL

Float glass manufacturing is not like the manufacturing of commodities like steel or plastic. Each of the production processes requires raw materials to be weighed, mixed, melted at high temperatures, formed into continuous ribbons, cooled and cut into a size that fits its use.

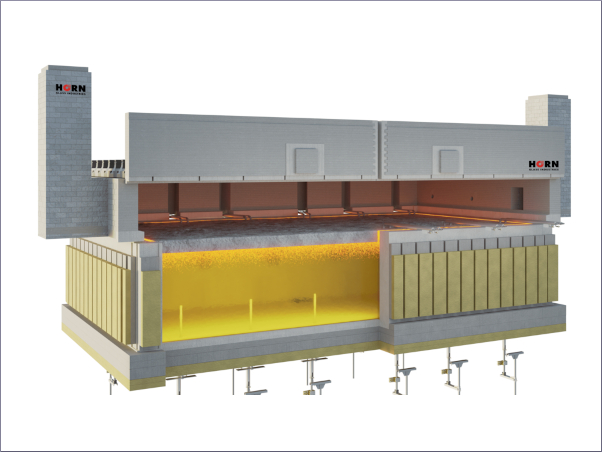

The melting furnace consists of refractory bricks and special shapes, support and binding steel, insulation, a fossil fuel firing system, temperature sensors and a computerized process control system. The furnace is carefully designed to meet the plant's specific gross daily glass production tonnage goals.

The insulation, special airflow features, and combustion air heating enable the furnace to operate at maximum fuel efficiency with negligible pollutant emissions. The furnace is sized and designed to provide high quality glass with the smallest amount of energy per ton of glass melted.

The float glass furnace can be operated with natural gas, LPG, biogas and oil. Additionally there is the possibility to install specially developed melting assistant devices like electrical boosting or bubbling systems.

Project management, Batch plant, Melting furnace (HORN), Forming, Annealing, Inspection, Packing, Utilities.

DESCRIPTION

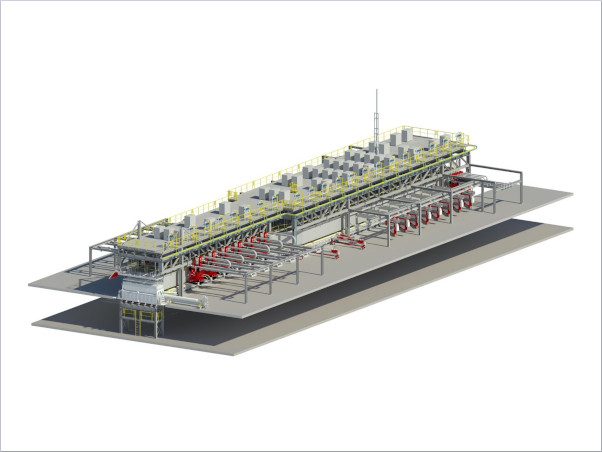

A complete technological plant on Turn-key basis for Float Glass or Container Glass production consists of raw material supply, glass melting, forming process, annealing, cold end, utilities and the corresponding project management. HORN provides the complete package together with its partner companies while the project management has a key role in this package.

JOBS

The Turn-key plant includes supply of service/ machines for:

- Project management

- Batch plant

- Melting furnace (HORN)

- Forming

- Annealing

- Inspection

- Packing

- Utilities

MELTING FURNACE

HORN, with its extensive experience, knowledge and expertise, designs different types of furnaces best suited to the various glass melting processes.

FOREHEARTH

The HORN system allows specific conditioning of the molten glass for each particular forming process while ensuring the highest possible temperature homogeneity of the gob and energy efficiency.

HEATING EQUIPMENT

Specially designed, in-house manufactured burners, as well as control skid units for using natural gas, heavy oil, light fuel oil or petcoke.

MACHINES AND UNITS

HORN’s machines and units are manufactured in its own workshop with a high vertical integration of the engineering office. Machines and units are supplied for batch charging, float glass forming on tin bath or flat glass annealing.

ELECTRICAL EQUIPMENT

Different levels of process control and tailor-made solutions to satisfy our customers' requests by using the most reliable and durable equipment, assembled and tested in our workshop.

PERIPHERAL EQUIPMENT

High quality products relating to the furnace, manufactured in our modern production area. Constantly improved and adapted to each individual production process and according to international standards and norms.

SERVICES

Special service division for execution ranging from furnace drain through demolition to supervision of erection and including heat-up and special maintenance services during operation for an extended furnace lifetime.

EUROX

- Oxygen measurement System DiRox1500-elpro-OM3-D-1/2

for Regenerative Glass Furnaces, crown installation with 1 or 2 Sensors

Inclusive Evaluation Unit OM3

- Oxygen measurement System DiRox1500-dipro-OM3-D-1/2

for oxy-gas recuperative Glass Furnaces flue gas channel, crown installation with 1 or 2 Sensors

Inclusive Evaluation Unit OM3

- EpRox1000-FH-OM3-E-T08/12 Oxygen measurement System for Forehearth / Feeder-heating

for Gas/Air-Premix Combustion Control

- EpRox1000-FL-OM3-E-T08/12 Oxygen measurement System for Float Glass with gas extraction

for Dry Process Gases (N2, N2/H2 mixes)