This paper was first presented at GPD 2025.

Link to the full GPD 2025 conference book: GPD_2025_ConferenceProceedingsBook.pdf

Author: Kai Vogel

Viprotron GmbH, Germany

Abstract

Viprotron has developed a new technology for the exit of the furnace, that allows the measurement of the distortion of tempered glass with high precision and unparalleled repeatability. The patented “True Edge Technology” used for this purpose makes it possible to start the measurements right at the glass edges and not just with an offset. This allows the edge kink at the leading and trailing edge to be measured with a high degree of precision. Such exact measurement results are important, especially when tempered glass is further processed into laminated safety glass. But this technology also measures the center areas with high precision, so architects can rely on the documented measurement results with regard to the final aesthetic appearance of the tempered glass, in order to be able to classify the quality of the final façade accurately.

Article Information

- Published by Glass Performance Days, on behalf of the author(s)

- Published as part of the Glass Performance Days Conference Proceedings, June 2025

- Editors: Jan Belis, Christian Louter & Marko Mökkönen

- This work is licensed under a Creative Commons Attribution 4.0 International (CC BY 4.0) license.

- Copyright © 2025 with the author(s)

1.The need to become better

Even if manufacturers have continuously optimized their furnaces in the past, the measurement of optical distortions like pockets, hammers, saddles, etc. as well as rollerwaves (leading, center, trailing) and edge kink remains of main importance. The overall flatness control is executed with the new patented „True Edge™“ technology, which controls the glass from edge to edge over the complete length of the glass! This enables a focus on the condition of the glass edges, which are highly important for later processes like lamination or IG.

The need to drive the furnaces to their limits for productivity reasons involves the risk that they are sometimes easily exceeded. This then leads to a loss of quality. However, in order not to exceed the limits as far as possible, suitable tools are required. This applies in particular to optical distortions in the glass caused by the furnace, which not only cause claims in the final product, but also problems with possible further processing into laminated or insulating glass. The Temper Scanner technology is a perfect tool to optimize tempered glass quality with this new True Edge™ function of distortion measurement.

2. The measurement process

Many years of experience in the use of line scan cameras enabled Viprotron to use this highperformance technology in the field of distortion / rollerwave measurement as well. With a new geometry-based direct reflection measurement approach, every 0.5 mm the approach determines the local distortion in Millidiopters as well as in Millimeters (Peak – Valley) and shows exactly where the problem areas in the glasses are.

All manifestations of distortion (local saddles or pockets, edge kink and bows) are covered with this dense measurement approach as well. The measurement is taken in the direction of the travel of the glass through the furnace and is verified with cross direction calculations. This ensures the highest level of result repeatability.

2.1. Set up of the Temper Scanner (Distortion channel)

The setup is as follows:

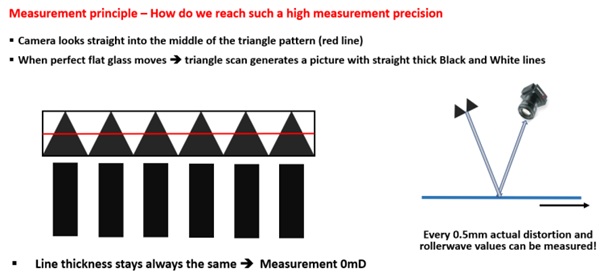

- Two measurement heads are precisely aligned to the same position on a geometric triangle light pattern

- The triangle light pattern is placed right beside the cameras on top of the structure

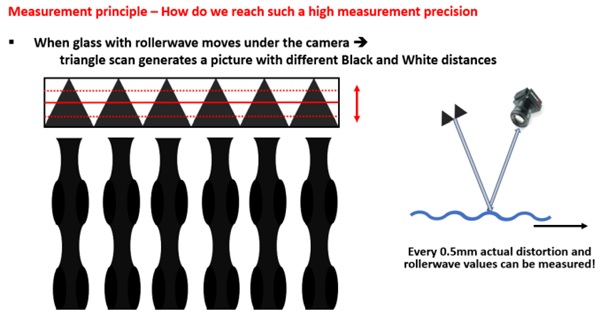

Each and every 0.5 mm one measurement is taken. Here are two examples. First a perfect flat glass (e.g. float, not tempered) and second a tempered glass with rollerwaves. The first glass provides no distortion, so the cameras (red line) look always in the same position on the triangles.

The second glass provides distortion in a rollerwave shape, so the cameras will catch varying distances between the black and white triangles. In this case “perfect” rollerwaves come up. Saddles or pockets, etc. will have different patterns. Using respective algorithms typical and non-typical appearances can be identified.

2.2. Key Performance Indicators

Below you find the key performance indicators:

- High measurement resolution up to 4 mD independent of conveyor speed

- Patented “True Edge™” technology cameras cover the complete surface of a glass.

- Exact measurement over the whole glass from edge to edge every 0.5 mm without interruption

- Measurement range: -550mD to +550mD

- Glass thickness: 2 - 20mm

- Glass types: Clear and tinted

- Glass Coatings: Almost all hard and soft coatings; Low-E, solar control, etc.

- Exception: Anti-reflective coatings

- Automatic adaptation to the reflection level of the coating

3. Issues in the Field

3.1. Surface and architectural aesthetics

The most evident claim reason, which can be avoided by using the results of an ideal measurement tool after the furnace is the distortion on the complete surface of the glass. In the meantime, nobody accepts anymore bias in a degree like shown in Fig. 5.

To avoid these claims a reliable distortion scanner can help optimize the furnace settings.

3.2. Edge area control and later processing

It is always a big issue for laminators, when glass comes out of the pre-lam process waiting to enter the autoclave, and the edges need to have clamps/brackets to close gaps between the tempered sheets. First, when having process stability in tempering, clamping the edges is unnecessary. Second, when the edges are not under different physical conditions, there is no danger of delamination later in the field. That is the same for IGs, which can be separated by the physical behaviour of the glasses and will end in early condensation within the warranty period.

4. Furnace Optimization

The way to come around the issues named in chapter 3 is the optimization of the furnace settings using a reliable data generator. This is the original task of this new distortion measurement in the Temper Scanner. But when is a data generator reliable? It is reliable when it delivers the same results under the same or similar conditions. So, the repeatability of the measurement results is the key factor.

4.1. Repeatability tests under the same conditions (30 times neutral test)

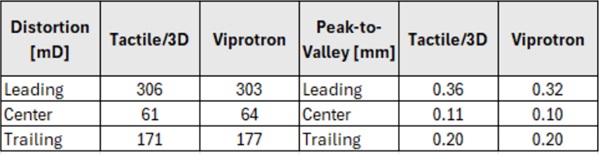

To have trustful results of the distortion channel accuracy, Viprotron has provided a 6mm glass sample of 1mx1m to a neutral test lab, where the testers executed a check with a digital tactile measuring equipment on a granite table in an air conditioned environment. Later the same glass was measured under the exact same conditions 30 times after a furnace equipped with the new Viprotron technology.

The direct comparison between the tactile lab measurement and the measurement results of the new “True Edge™” technology of the Temper Scanner reflects the high precision of the direct measurement of the center, the leading and trailing glass edge distortion. The measurements of the optical distortion in millidiopters as well as the measurements of the “Peak to Valley” values in mm only show very small deviations.

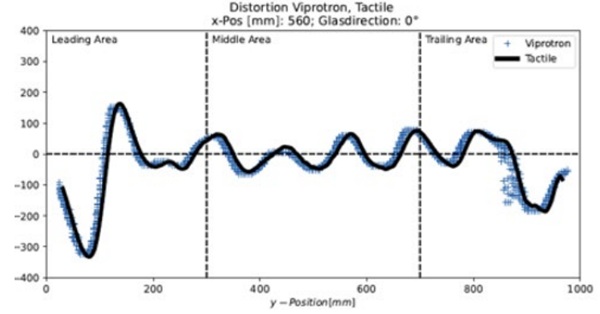

The following repeatability tests show the high precision of the new technology even better.

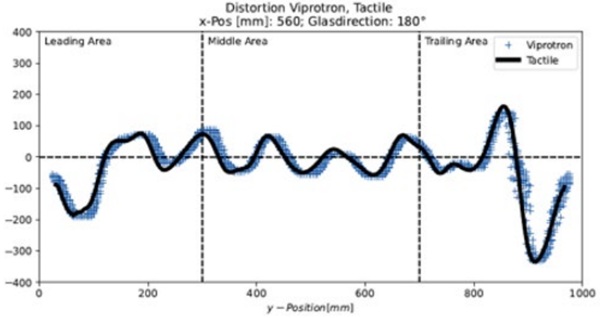

The next image shows the tactile measurement as a continuous black line. The large number of blue crosses represent the 30 repetitions of the measurement by the True Edge™ Technology of the same glass. The high recurring accuracy of the measurement and the high level of agreement with the tactile values can be clearly seen in that the blue crosses only deviate slightly from the black line and there are no outliers within the group of crosses.

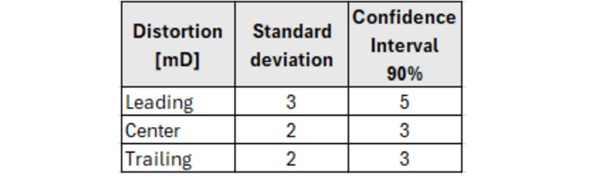

The following table shows the statistical deviations of the repeatability measurement. For the 30 repeatability measurements, this shows a maximum statistical deviation, calculated once in the standard deviation and once in the 90% confidence interval, of 2mD to a maximum of 5mD, which virtually corresponds to the measurement resolution of ±4mD.

The same test was performed with the same glass but turned 180° while travelling through the measurement equipment. As we can see in Fig 9 the waviness was turned 180° but the results were comparable.

4.2. Repeatability tests on different areas of the conveyor (customer test)

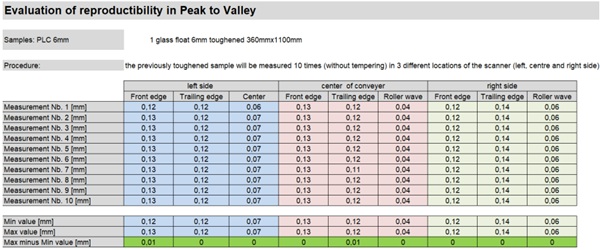

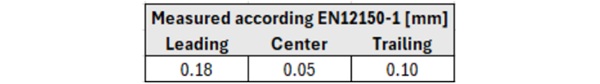

With a glass taken from the normal production of a tempered safety glass manufacturer, another repeatability test was carried out at the furnace exit of a Viprotron customer that has the new True Edge™ technology. This time with the aim of checking not only the absolute repeatability but also the lateral repeatability perpendicular to the conveyor belt. Furthermore, particular emphasis was placed on the measurement in Peak to Valley. The customer then measured the glass manually in accordance with the European standard EN12150-1 to check and verify the measured values.

For this purpose, a 6 mm thick coated glass was run through the Temper scanner on three measuring tracks a total of 10 times per measuring track. Measurements were taken on the left side, in the middle and on the right side of the conveyor belt.

The results in Table 10 show a repeatability with only insignificant differences, even though the measurements were carried out at three different locations on the conveyor belt. The table shows only minimal deviations of a maximum of 0.01 mm in the repeat measurement at one location on the conveyor. However, the different measurement tracks on the conveyor belt also show a variation in the measured values of 0.12 to 0.13mm for the leading edge and 0.11 to 0.14mm for the trailing edge and 0.04 to 0.07mm in the center. Thus, there was only a maximum deviation in repeatability of less than ±0.03mm across all measurement tracks.

None of the above values failed the requirements (± 0.16mm). Only two values differed in the respective column by 0.01mm, which is more than ten times better than the requirement. A benchmark result, which was never achieved before.

5. Summary and Outlook

This new technology provides an accuracy and repeatability level that has never been reached before. Today this technology can be perfectly used to ensure only superior quality of the tempered glass will be shipped to further downstream processes or to the customer. Furthermore it is used today to optimize the furnace settings manually. Tomorrow the development must be to “translate” the findings and results in a data set transfer to automatically adjust the furnace settings, when deviations come up.