This paper was first presented at GPD 2025.

Link to the full GPD 2025 conference book: GPD_2025_ConferenceProceedingsBook.pdf

Author: Thomas Rainer, Hegla boraident GmbH & Co. KG, Germany

Abstract

In the last decade the demand for new functions in building glass products has grown dramatically to realize smart window applications. The realization of these new functions leads to the development of glass processing technologies using laser radiation. By means of laser radiation it is possible to change a broad range of properties of the window glass product. Those laser structures can be seen by the naked eye as well as to be invisible. The new generation of laser scanning technologies speed up the existing laser processes dramatically. This gives the possibility to connect laser processes with existing IGU production processes and reduces manufacturing costs and production time. Furthermore, an optimization of the production sequence of IGU’s is the consequent result of usage these new technologies. For this laser induced processes examples of laser applications will be presented as well as the process tool. In addition, this technology can also be used to recycle old IGUs. Cleaning and stripping processes on dismantled IGU panes lead to a new use of glass that has already been used.

Article Information

- Published by Glass Performance Days, on behalf of the author(s)

- Published as part of the Glass Performance Days Conference Proceedings, June 2025

- Editors: Jan Belis, Christian Louter & Marko Mökkönen

- This work is licensed under a Creative Commons Attribution 4.0 International (CC BY 4.0) license.

- Copyright © 2025 with the author(s)

1.Status of Laser Glass Processing

Thanks to laser technology, the glass industry can do something that would be almost inconceivable in any other sector. Laser finishing treatment enables manufacturers to enhance the value of largely standardized products and increase their functionality. With prices for traditional IG units and facade cladding coming under increasing pressure, using laser upgrades to create bird protection glass, RF-transparent glass and anti-bacterial glass gives manufacturers the chance to tap into new target markets and increase their profit margins.

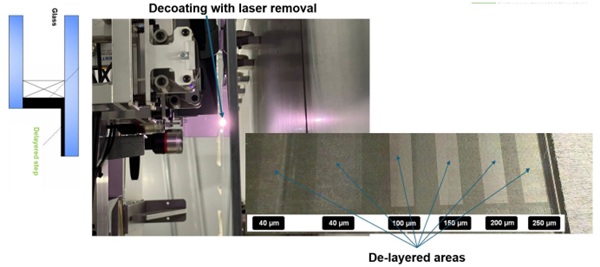

Whether you want to perform edge decoating or partial coating removal to create lighting effects, laser technology makes the process gentle and precise. The lasered area is crystal-clear and free of scratches, which means this form of decoating produces perfect results even for the high standards of structural glazing and visible areas in general. The surface of the glass remains completely intact, as do its dazzling looks.

Until now, laser technology for decoating coated glass has been integrated into flat glass production as a standalone station. The reason for this integration was the long processing times of the laser decoating process. However, there is a growing need to integrate laser technology with existing manufacturing processes, such as insulating glass production. This requires a reduction in the processing times for the laser process. The necessary process analysis and a possible solution to the problem are described in the following sections.

2. Task – Find the Bottleneck

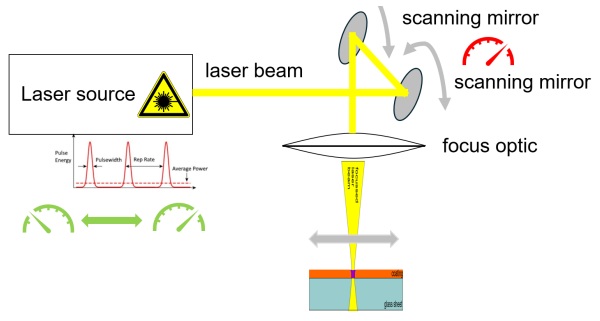

The following diagram shows the sub-processes of a laser system.

While highly repetitive laser sources have been introduced to the market in recent years, the optical deflection systems, so-called optical galvo scanners, are the speed-limiting factor of laser processing technologies.

With these galvo-scan systems, typical speeds of 1 to 2 meters per minute are possible for a 20 mm wide decoating track, e.g. to produce standard insulating glass.

However, for the production of stepped insulating glass, decoating widths of 50 mm to 80 mm are necessary. In addition, a process speed of at least 5 meters per minute is required to integrate the laser process with the insulating glass line for these wide development lanes.

To meet these requirements, the use of alternative scanning technologies for the laser decoating process was examined.

3. Solution – Polygon – Scanning System

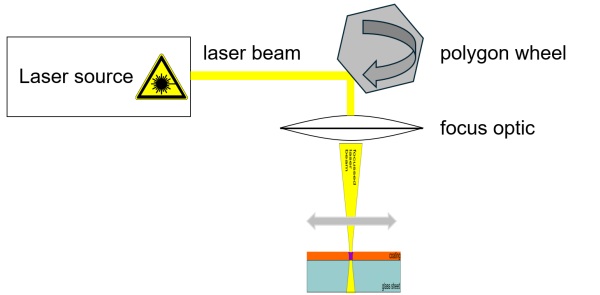

In contrast to a galvo scanner with an oscillating mirror, the laser beam deflection in a polygon scanner is achieved by a rapidly rotating wheel with several mirror surfaces acting one after the other. With a polygon scanner, the entire scan line is always traversed. This is advantageous for area laser processing. The following diagram shows a laser system with a polygon scanner.

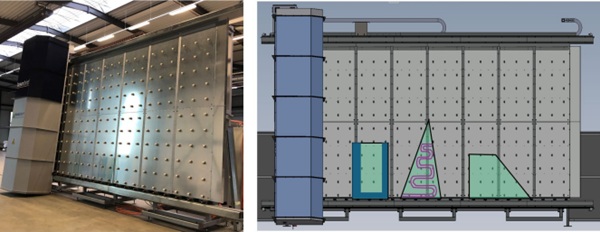

Polygon scanners are not yet widely used in materials processing. For the application of surface decoating of coated glass surfaces, the use of polygon scanners and matching laser sources was tested. It was shown that a suitable laser system technology could be configured that meets the requirements to produce stepped insulating glass.

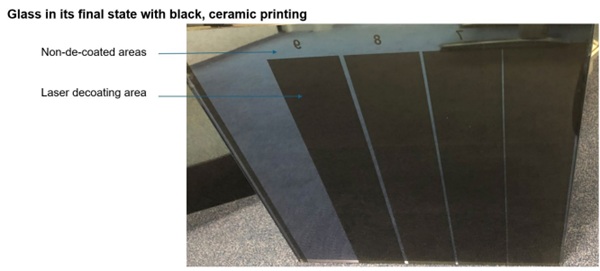

The following image shows partially decoated glass that was printed with black ink after the laser decoating process. The decoating traces are characterized by very high optical quality, which meets the requirements for the layering steps for insulating glass.

The 100 mm wide decoated tracks were produced at a speed of 6 meters per minute.

4. Summary

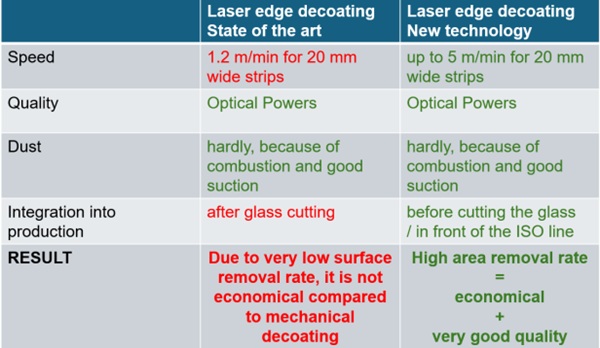

The presented results showed that, using alternative scanning technologies, it is possible to integrate laser processing technologies with existing manufacturing technologies, such as insulating glass production. The following table summarizes the differences between existing laser stripping technologies and laser stripping technologies using polygon scanners.

Table 1: Comparison of different scan technologies.