This paper was first presented at GPD 2025.

Link to the full GPD 2025 conference book: GPD_2025_ConferenceProceedingsBook.pdf

Author: Nele Deckers, ORION Laser Tech, Belgium

Abstract

Laser technology, an essential tool in modern industries, is poised to play a pivotal role in the coming decade, especially in glass processing. As a high-precision method, laser-based techniques are revolutionizing traditional manufacturing processes. This paper explores how lasers compare to conventional glass processing methods such as CNC machining, acid etching, and sandblasting. The benefits of laser cutting, cleaving, marking, and selective coating removal are highlighted, demonstrating its potential in industries such as architecture, telecommunications, and automotive manufacturing. Innovations like bird-friendly windows, enhanced indoor connectivity through laser-modified coatings, and switchable glass solutions underscore the significance of laser advancements. This paper will analyse how laser technology surpasses conventional techniques in efficiency, sustainability, and precision, thereby driving the future of glass applications.

1. Introduction

A laser (Light Amplification by Stimulated Emission of Radiation) is a device that emits a highly focused beam of light at specific wavelengths. Since its invention, laser technology has found applications in healthcare, defence, consumer electronics, and industrial manufacturing. One of its most transformative applications is in glass processing, where its precision and versatility provide an edge over traditional methods. This paper explores why industries are increasingly shifting to laser-based techniques and how this transition is shaping the future of glass applications.

2. Fundamentals of Laser Technology

Lasers operate based on the principle of stimulated emission, where an external energy source excites atoms or molecules to a higher energy state. When these excited particles return to their ground state, they emit photons in phase with the stimulating photons, resulting in a coherent and monochromatic light beam. Key characteristics of laser light include:

- Coherence: All emitted photons have a fixed phase relationship, enabling the light to be focused to a small spot with high intensity.

- Monochromaticity: Lasers emit light of a single wavelength, allowing for precise targeting in applications.

- Collimation: Laser beams are highly directional and spread minimally over distance, making them ideal for applications requiring long-range precision. These properties make lasers particularly suited for tasks that demand high accuracy and minimal material interference, such as cutting, engraving, and surface modification.

3. Laser Technology in Glass Processing

The integration of lasers into glass manufacturing has enabled highly specialized processes such as:

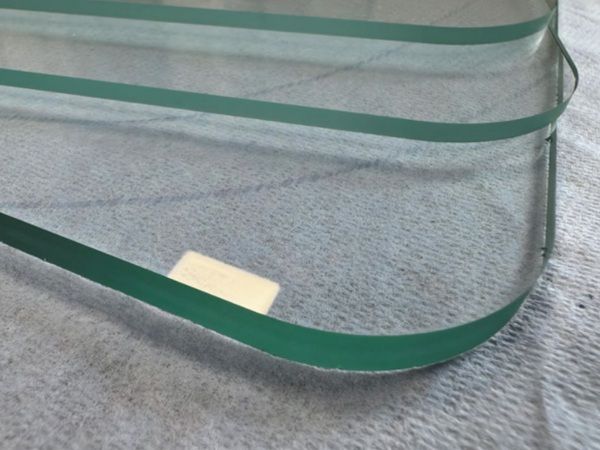

- Glass Cutting and Cleaving: Ultrashort laser pulses are emitted along the desired cutting path, resulting in exceptional edge quality. Glass thicknesses of 3–4 mm can be cut in a single pass, while thicker glass can be processed through multi-pass lasering combined with consecutive breaking or cleaving, leading to fully automated production lines. This method allows for unlimited designs and shapes, including internal contours. Perfect solution for windshield, sidelites & backlites, mirrors, designer shaped glass and any other custom shapes. Main features: outstanding cut edge: without visual chipping, no grinding is necessary after cutting; our technology is suitable for any type of glass: clear glass, green glass, coated glass and mirrors; productivity: cutting, cleaving or breaking speeds go up to 2/ms.

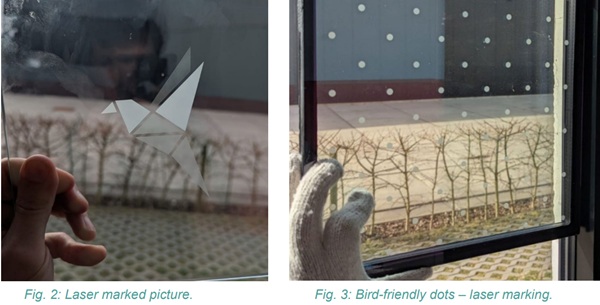

- Glass Marking and Engraving: Laser marking, laser etching and laser engraving are all different words for the same process. The ablation process selectively removes tiny layers of the glass top surface without affecting the structural strength. It results in a sandblasted or frosted effect on the glass surface. A variation of whiteness, gloss index and visibility of the markings can be created by changing the process parameters. It is a perfect solution for: bird-friendly markings, design & frost effects, custom patterns & shapes, QR code & barcode tracing. Main feature: any size and shape is possible: birdfriendly markings in any size & shape, gloss index and appearance; preserves glass strength: testing shows that mechanical properties are not compromised (Bird-friendly laser treatment verified as safe for glass strength | Orion Laser Tech).

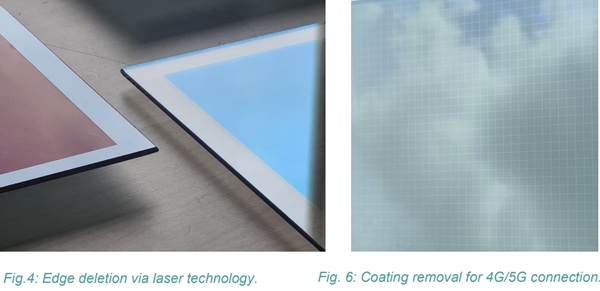

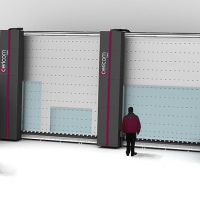

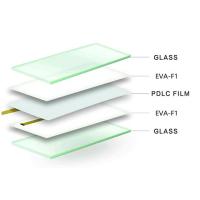

- Selective Coating Removal: This ablation process selectively removes coating. Various coatings are precisely removed by laser, going down from thin lines up to complete surface areas. Our laser scribing technology can create lines that are invisible to the human eye. By using lasers, coatings on architectural and automotive glass can be selectively removed to enhance functionality, such as improving indoor 4G/5G signal penetration. This feature is becoming increasingly important: new buildings, as well as trains, are equipped with coated glass to block sunlight. However, besides sunlight, this also blocks the 4G/5G mobile network, resulting in poor reception in these new trains and buildings. Ablation using a laser offers an excellent solution for this. Another example is the process of edge deletion of the coating: now the coating around the perimeter of a glass pane is removed, often prior to assembly in an IGU (insulating glass unit).

Main features: various coatings, flexible width, numerous patterns, invisible grids, enabling vision and radar technology for autonomous cars and ADAS, freedom of design.

These techniques offer enhanced customization, better quality control, and increased sustainability by reducing material waste.

4. Comparison with traditional methods

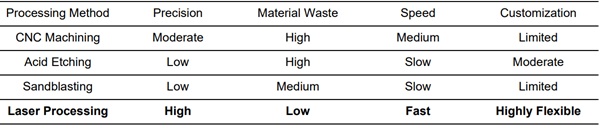

Traditional glass processing techniques, including CNC machining, acid etching, and sandblasting, have been industry standards for decades. However, they present several limitations:

- CNC Machining: Involves mechanical cutting tools that can introduce microfractures and require frequent maintenance. The process generates significant material waste and is limited in the complexity of shapes it can produce.

- Acid Etching: Utilizes hazardous chemicals to create patterns or frosted effects on glass surfaces. This method poses environmental and safety concerns and offers limited precision and repeatability.

- Sandblasting: Employs high-pressure abrasive materials to erode glass surfaces. While effective for creating textured finishes, sandblasting lacks precision and can weaken the glass structure. In contrast, laser processing offers significant advantages:

- Precision: Laser technology achieves high precision, allowing for intricate designs and complex shapes that are challenging for traditional methods.

- Material Waste: The non-contact nature of lasers minimizes material waste, as there is no physical tool wear or debris generation.

- Speed: Laser processes are typically faster, reducing production time and increasing throughput.

- Customization: Lasers provide unparalleled flexibility in design, enabling rapid prototyping and customization without the need for new tooling. The table below summarizes the comparison:

Table 1: Comparison with Traditional Methods.

Laser processing eliminates the need for physical contact, reducing damage to delicate surfaces. Unlike CNC machining, which requires expensive tooling, or acid etching, which involves hazardous chemicals, laser methods are more environmentally friendly and cost-efficient.

5. Key applications and future potential

Several industries are already leveraging laser-based glass processing:

- Smart Buildings and Architecture: Laser-modified glass coatings enable improved wireless connectivity, crucial for modern smart buildings.

- Automotive Industry: Lasers are used for precision removal of coatings on vehicle glass, enhancing driver safety and reducing manufacturing costs. Also the cutting of special glass in 3D (curved in several directions) is an option with a laser.

- Bird-Friendly Glass: Laser marking techniques create patterns that make glass visible to birds, preventing collisions while maintaining transparency.

- Electronics and Display Technology: Laser-based structuring enhances touchscreens and flexible glass applications in smartphones and wearables.

Future advancements in laser technology will continue to drive innovations, such as heatable and switchable glass for energy-efficient buildings and improved optical components.

6. Conclusions

The shift toward laser-based glass processing is driven by the need for higher precision, sustainability, and efficiency. Compared to traditional methods, laser technology reduces material waste, eliminates harmful chemicals, and enables customization at an unprecedented level. As industries continue to adopt laser solutions, the coming decade will see significant advancements in smart glass applications, architectural innovations, and automotive improvements. The role of lasers in glass manufacturing is set to expand, offering limitless possibilities for precision engineering and functional design.

Comments

This document examines the reasons behind the growing trend of industries adopting laser-based methods and the impact this shift is having on the future of glass applications.

Insightful and forward-looking this clearly shows how laser technology is redefining precision, sustainability, and innovation in glass processing. pool screen repair