This paper was first presented at GPD 2025.

Link to the full GPD 2025 conference book: GPD_2025_ConferenceProceedingsBook.pdf

Authors: Cas Maertens a, Bert Van Lancker b,c, Dieter Callewaert b, Jan Belis b, Roman Wan-Wendner b

a. Ghent University, Belgium

b. Ghent University, Belgium

c. vitroplena, Belgium

Abstract

The G2C (Glass-to-Concrete) research project, a collaboration between Ghent University, fischerwerke GmbH & Co. KG and vitroplena bv, explores potential applications of glass-to-concrete bonding in building construction. The project aims to push the boundaries of traditional building materials by integrating glass with concrete, combining their unique properties to create innovative, aesthetically appealing and structurally advanced solutions. A recent showcase at the Glass Technology Live exhibition during Glasstec 2024 demonstrated several potential applications of this technology through a pedestrian bridge demonstrator. This paper focuses on the production and assembly aspects of the bridge. As the first full-scale structure implementing glass-to-concrete bonding, this project provided valuable insights into bonding procedures, assembly-related problemsolving and logistical planning. These practical aspects are crucial to assessing the feasibility of glassconcrete bonding and its potential in real-world applications, beyond the bridge's structural performance. The 5.5-meter walkway features a 3-meter-span hybrid floor panel made of fibrereinforced high-strength concrete with glass plates bonded to the top and bottom. The panel’s unique triangular openings not only reduce weight but also increase transparency, enhancing both the aesthetic and functional properties of the structure. T-beams are integrated within the hybrid panel: the edges of the panel form the web of the T-beam, while the curved glass web provides additional stiffness. Glass balustrades are seamlessly bonded to the 8 cm thick concrete slab, enhancing both stability and the overall aesthetic flow. The floating staircases, constructed using a concrete mix excluding cement, are supported by structural glass side panels which also serve as balustrades. Each segment of the bridge - the hybrid panel and two staircases - is designed for transport by truck.This showcase highlights the potential of bonded glass-concrete elements to combine aesthetic appeal with structural integrity, offering exciting possibilities for the future of hybrid (glass-to-concrete) structures.

Article Information

- Published by Glass Performance Days, on behalf of the author(s)

- Published as part of the Glass Performance Days Conference Proceedings, June 2025

- Editors: Jan Belis, Christian Louter & Marko Mökkönen

- This work is licensed under a Creative Commons Attribution 4.0 International (CC BY 4.0) license.

- Copyright © 2025 with the author(s)

1. Introduction

The construction industry has long relied on traditional building materials such as concrete and steel to create functional and durable structures. However, as the demand for more sustainable and aesthetically diverse solutions increases, the potential to integrate new materials and innovative techniques has become a significant area of exploration. Hybrid construction, which in this case combines glass and concrete, presents an exciting opportunity to push the boundaries of conventional design and unlock new possibilities for both architectural expression and structural efficiency.

Glass has a high compressive strength and a relatively high tensile strength, excellent durability, and strong resistance to environmental factors like weathering and temperature changes (Achintha, 2016; Narayanasamy et al., 2018; Udi et al., 2023). On the other hand, concrete contributes significant compressive strength, stability, and versatility. When these two materials are combined the result is a hybrid structure that takes advantage of both. The combination enhances structural performance while offering innovative design opportunities that are not only visually attractive but also functional.

The G2C research project is a collaborative initiative involving the Department of Structural Engineering and Building Materials at Ghent University, fischerwerke GmbH & Co. KG and vitroplena bv. It investigates the potential applications and structural behavior of glass-to-concrete bonding in modern construction. By developing new methods to integrate glass with concrete, the project aims to deliver advanced solutions that leverage the durability and strength of concrete with the transparency and unique aesthetic qualities of glass. Ultimately, the project seeks to demonstrate the practical implementation of this bonding technology, paving the way for innovative architectural designs that are both visually striking and structurally efficient.

In the scope of this research, a full-scale practical application was developed in the form of a pedestrian bridge, specifically designed as a showcase for the Glass Technology Live exhibition during Glasstec 2024. The goal was to demonstrate the innovative potential of glass-to-concrete bonding, inspiring new architectural possibilities while highlighting the structural and aesthetic advantages of this hybrid approach.

By leveraging on the performance attributes of glass and concrete, the project illustrates how these materials can complement each other to create structures that are not only stronger and more durable but also visually striking. Presenting the bridge as a full-scale demonstrator aimed to capture the attention of industry experts, architects and engineers, encouraging the exploration of new design concepts and construction techniques.

This paper aims to provide an review of the G2C pedestrian bridge, with a specific focus on the production and assembly processes that were integral to the realisation of the project. The primary goal is to explore the challenges encountered during production and assembly, as well as the solutions developed to overcome these obstacles. By examining the practical aspects of this case study, the paper offers valuable insights into the application of glass-to-concrete bonding technology and its potential for future use in construction. Additionally, the paper discusses the aesthetic and functional aspects of bonding glass to concrete, as well as its scalability for larger, more complex infrastructure projects.

2. Design of the demonstrator

2.1. Objectives and challenges

The primary objective of this project was to showcase the potential of G2C bonding in a functional and visually appealing structure. The research conducted throughout the project explored various applications of bonding glass to concrete, with a focus on aspects such as structural performance, aesthetics, production processes and durability. The showcase at the Glass Technology Live exhibition during Glasstec 2024 was designed to demonstrate several potential applications of this innovative technology in a real-world context. This demonstrator marked the first full-scale structure to implement glass-to-concrete bonding, offering valuable insights into the practical challenges and considerations of applying this technology in real-world settings.

Key considerations during the design process included several important factors. First and foremost, the showcase had to be feasible for production at Ghent University. Additionally, and perhaps the most critical factor, the bridge needed to be transportable by truck to the exhibition in Düsseldorf, Germany. This transport requirement imposed strict limitations on the bridge’s weight, dimensions and overall design. The structure also had to stand independently, without being anchored to the ground or requiring any foundation, as it needed to be movable and adaptable for display purposes at the fair. Furthermore, the transportation process itself introduced additional challenges, such as the need to account for vibrations and accelerations that could be induced during transit. Finally, the design had to facilitate easy assembly and disassembly. It was also essential for the bridge to be sufficiently mobile to allow for handling with a forklift. These practical constraints had a significant impact on the design decisions and the overall approach to the project.

2.2. Design concept

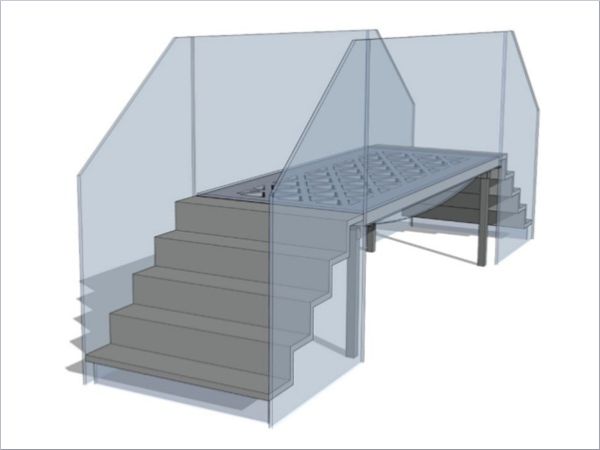

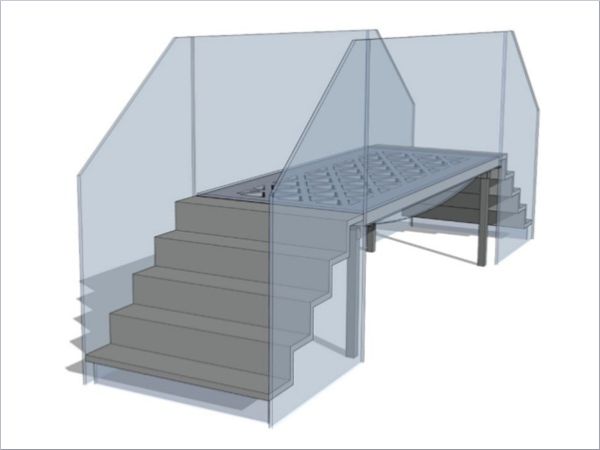

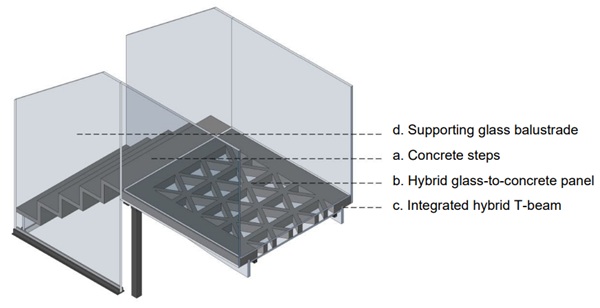

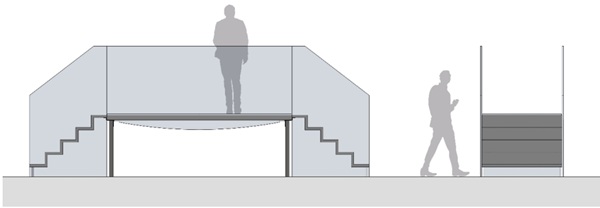

As a result of the aforementioned criteria, the showcase took the form of a pedestrian bridge (see Fig. 1). The design highlights several key applications of glass-to-concrete adhesive bonding, where both glass and concrete collaborate to enhance durability, structural performance and aesthetic appeal of the bridge. The different applications integrated into the design are shown in Fig. 2.

a. The first integrated application of glass-to-concrete bonding is the staircase. The concrete steps are directly bonded to the glass side panels, which provide full support for the concrete. The adhesive joint follows the exact contours of the stairs, creating a visually light effect while also demonstrating the structural role of the glass, as it helps support the staircase and contributes to its overall stability.

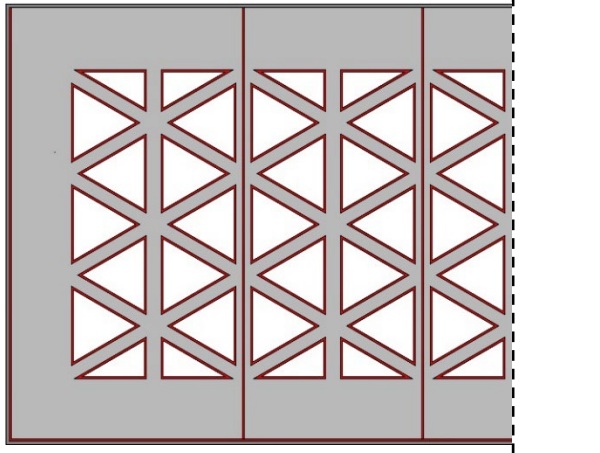

b. The central section of the bridge features a hybrid floor panel with a span of 3 meters. The panel consists of a slender concrete core with triangular openings, which is stiffened by glass plates bonded to both the top and bottom surfaces of the concrete slab. The concrete core incorporates strategically placed openings to reduce weight and improve transparency. The glass plates, bonded to both sides, enhance the overall stiffness of the panel, providing structural integrity while contributing to its visual lightness.

c. The hybrid panel incorporates T-shaped beams along its sides. These beams feature a concrete flange that extends into the panel, with a notch within the flange to accommodate a vertical glass web. The glass web is securely bonded, completing the beam’s structure. The glass web is shaped to align with the moment line of the beam, as displayed in Figure 3. This optimises load distribution, contributing to both the strength and efficiency of the beam’s design.

d. Lastly, full glass panels are bonded to the sides of the central section, forming the balustrades. These glass panels provide both safety and a sleek, uninterrupted aesthetic, seamlessly integrating with the overall design of the bridge. Additionally, they increase the overall stiffness of the hybrid floor panel.

2.3. Materials

The bridge is constructed from three primary materials: glass, concrete, and adhesive, resting on a steel frame. Given the structural role of the glass, thermally toughened laminated glass was chosen for the side panels of the staircase and the balustrades of the central section. This glass (1010.4) consists of two 10 mm glass sheets with a structural interlayer. For the top and bottom glass plates of the hybrid sandwich panel, as well as the glass web in the T-shaped beam, a thinner glass (88.4) was used.

The concrete core for the hybrid panel was manufactured in the Magnel-Vandepitte Laboratory at Ghent University. Steel fibre reinforced concrete was chosen because previous experiments within the G2C research project demonstrated that the addition of fibres increases the tensile strength of the concrete and reduces the risk of brittle fracture. This is particularly important as the glass is bonded to the concrete surface, where local stress peaks can occur, potentially leading to brittle failure. By using steel fibres, this risk is significantly reduced, enhancing the overall safety of the structure. While steel fibres are often avoided in visible concrete elements due to likelihood of rust stains to form over time, the glass plates ensure a lasting visual appeal.

Self-compacting concrete of type C40/50 was selected for the floor slab, produced with CEM II/A 52.5 N cement. Steel fibres with a length of 60 mm were added at a dosage of 35 kg/m³, and an accelerator was also used to optimise the setting time. Due to the complex formwork, consisting of a rectangular mould to shape the slab and solid triangular elements to create the openings, it was crucial that the concrete flowed smoothly into every corner of this intricate geometry. Therefore, the mix design featured a maximum aggregate size of 14 mm and achieved an S5 slump flow class, ensuring good workability and complete filling of the formwork.

The concrete steps were manufactured by an external partner. The concrete used for the steps is an Ultra-High-Performance Concrete (UHPC) with a strength class of C90/105, reinforced with steel fibres. This innovative mix reduces its carbon footprint with more than 80% compared to a standard mixture by using a binding agent made from secondary metallurgy by-products. Despite its sustainable composition, it maintains high strength and low shrinkage.

To bond the glass to the concrete, a transparent, low-viscosity epoxy from fischerwerke GmbH & Co. KG was primarily used. This epoxy is especially suited for glass applications as it remains clear when cured, allowing the concrete to remain visible through the adhesive layer. In areas requiring a thicker adhesive, a grey particle filled epoxy from the same company was used.

2.4. Steel frame

The designed pedestrian bridge has a total length of 5.50 metres, a width of 1.35 metres, and a height of 2.25 metres. Since the bridge in its full size would not be manageable with a forklift, it was necessary to divide it into three separate sections: the middle part and the two staircases.

Each section is built on a coated steel base frame, as shown in Figure 4, allowing the three frames to be securely connected on-site to form a single, rigid pedestrian bridge. The steel frame incorporates two parallel steel channels, allowing the elements to be safely lifted and transported using a forklift. During the exhibition, the steel frame was covered with a wooden floor, providing a seamless and visually appealing finish.

The glass side panels for the staircases are bonded to U-shaped steel profiles that provide secure anchoring and stability. The hybrid floor panel rests directly on its steel frame for support. To prevent lateral displacements, cylindrical elements are welded onto the steel support. These elements fit into specially designed recesses in the concrete slab, effectively locking the panel in place and ensuring overall structural stability.

The diagonal and top horizontal steel elements (see Fig. 4) are designed to limit horizontal displacement and are only necessary during transport. Under normal use, the bridge's loads do not cause significant horizontal movement of the columns, so the diagonals can be removed once the bridge is in place.

2.5. Design calculations

For each element, a finite element (FE) analysis was conducted to optimise and validate the design, ensuring compliance with the relevant standards in both serviceability limit state (SLS) and ultimate limit state (ULS). Given that this paper focuses on the production and logistics of the bridge, the detailed results of the analysis are not included. A more in-depth numerical investigation was conducted by Bert Van Lancker and is presented in Numerical investigation of bonded glass-to-concrete applications subjected to real-world design situations (in press).

3. Production and Logistics

3.1. Concrete casting

The concrete core of the hybrid floor panel was cast in Ghent University’s Magnel-Vandepitte Laboratory. Due to the unconventional design of the floor slab, which features triangular openings, a custom formwork had to be produced. The rectangular formwork was crafted by lab technicians using plywood. For the solid triangles, XPS plates were cut into the required triangular shapes and wrapped in plastic film to prevent adhesion between the concrete and the XPS. These solid triangles were then screwed into the base plate of the formwork to avoid them to float during casting, as shown in Fig. 5.

In addition to the triangles, other recesses had to be created in the concrete slab. Since the slab is supported by a steel frame, it was necessary to prevent horizontal movement between the concrete and the frame. To achieve this, cylindrical pins were welded onto the steel frame, requiring voids of the same negative shape in the concrete. This was done using PVC tubes with closed ends, which were mounted onto a beam and positioned on the formwork.

Where the glass fins for the T-shaped beams were to be placed, a notch with a depth and width of 20 mm was required to allow for proper bonding of the glass. A similar system was used here: a square steel profile was mounted on a beam and subsequently placed onto the formwork, ensuring precise alignment of the notches for the glass installation.

3.2. Adhesive bonding

The bonding process for attaching glass to concrete required different approaches depending on the location and type of connection. However, the general procedure remained consistent: first, the glass was thoroughly cleaned with isopropyl alcohol. Next, the concrete surface was cleared of dust using pressurised air, followed by wiping with a slightly damp cloth. The adhesive was then prepared according to the manufacturer’s specifications, ensuring optimal bonding conditions.

To form the hybrid floor panel, glass plates were bonded to both sides of the concrete core. The top side of the hybrid panel, which corresponds to the closed bottom of the formwork, was used to demonstrate full-area bonding. The bonding strategy involved vertically filling the void between the glass and concrete with a very liquid, transparent epoxy. The challenge stemmed from the triangular openings. To address this, all edges were sealed with double sided spacer tape, which ensured a fixed distance between the glass and concrete and created a closed void for filling. Transparent spacer tape was used for aesthetic purposes.

When the epoxy came into contact with the concrete surface, it caused a noticeable darkening. After curing, the concrete retains this darker shade, which made the position of the transparent spacer tape clearly visible, as the area beneath the tape remained unaffected by the epoxy. To prevent this and enhance the adhesion, all bonding surfaces were first coated with a thin layer of epoxy.

When placing the spacer tape at the edges, the surface was also divided into five zones using vertical lines of tape to complete the bonding process in a more controlled manner. Figure 7 illustrates the positioning of the spacer tape on the concrete surface, while Figure 8 displays the result after bonding.

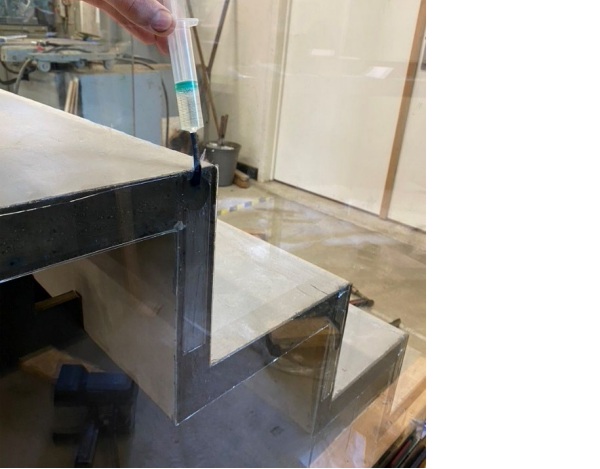

The bottom plate of the hybrid panel is bonded using point fixings because this side is rougher, being the open side of the formwork. This makes it difficult to seal with spacer tape. This bonding method requires a higher viscosity adhesive. A consistent volume of adhesive was applied for each dot using a syringe. Small spacers, made of the same epoxy and 1 mm thick, were placed to prevent the glass plate from settling too much. If the glass deflects more in certain areas and comes closer to the concrete, more adhesive would be squeezed out, making the dot larger. The spacers help control the distance between concrete and glass and maintain an even adhesive distribution. In addition to other practical benefits, the point fixings ensured airflow between the cavities and the environment, preventing moisture condensation.

The final component of the hybrid floor panel are the glass webs of the T-shaped beams. These glass plates are initially positioned vertically. Once aligned, the recess in the concrete is completely filled with the transparent, liquid epoxy, ensuring a secure bond between the glass and concrete.

After curing, the entire panel was flipped upside down and placed onto the steel frame, with an elastomeric pad positioned in between.

The staircases were bonded using the vertical filling technique with transparent spacer tape, creating a full-area bond along the side surfaces of the stairs. First, the concrete stairs were precisely positioned in terms of height and alignment with the steel frame. This was achieved by placing the stairs on a removable timber support of the correct height.

Once positioned, double-sided spacer tape was applied, forming sealed segments to ensure controlled filling. The glass panels were then placed on the sides, and each segment was filled vertically from the stair’s interior, ensuring a continuous adhesive layer over the entire surface.

The final elements bonded were the glass balustrade panels of the middle section, using a full-area bond with transparent epoxy. Given the bridge’s aesthetic requirements, precise alignment was crucial to ensure a seamless visual transition, especially considering the three separate sections that needed to match perfectly.

First, all elements were positioned and levelled. Once the concrete components were aligned, spacer tape was applied, followed by the glass panels. To ensure continuity in the top edges of the staircase and balustrade glass, temporary wooden clamps were used to keep them perfectly aligned in the same plane. The sealed voids were then filled with the transparent epoxy from the inside of the balustrade. Temporary vertical L-shaped steel profiles, attached to the steel frame, supported the glass panel during positioning, curing and transport.

Once the bonding process was completed, the bridge was prepared for transport. Given the presence of glass elements, it was essential to protect them from potential impacts and excessive movement during transit. To achieve this, protective cages made from OSB boards were constructed to shield the glass edges and temporary stiffeners were installed. Subsequently, the three sections were carefully loaded onto a truck for transport to Düsseldorf.

On-site, the pedestrian bridge was assembled. The temporary diagonal steel supports were removed, and a wooden floor was installed, covered with white carpet. The pedestrian bridge was accessible and walkable during the Glass Technology Live event at Glasstec 2024, held from October 22 to 25.

4. Lessons Learned

Throughout the design, fabrication, and assembly of the G2C pedestrian bridge, several challenges and insights emerged. These key observations provide valuable guidance for future projects involving hybrid glass-concrete structures. As this pedestrian bridge was the first full-scale application of this bonding technique, certain challenges only became apparent during the construction process, providing valuable lessons for future implementations.

One key challenge was handling and rotating large, heavy components, especially with glass already bonded to concrete. The lack of integrated lifting anchors made it difficult to manipulate these elements safely and efficiently. In future projects, casting dedicated anchors during concrete production would significantly simplify the handling process and enhance safety.

Another challenge was that the initially designed tolerances were too small, which led to alignment difficulties during assembly. This required adjustments on-site, which could have been avoided with more generous tolerance allowances in future designs. By allowing for larger tolerances, these alignment issues can be minimized, reducing the need for last minute modifications and enabling smoother assembly.

The bonding system, which used transparent spacer tape combined with liquid epoxy, performed well on smooth surfaces. However, on rougher areas such as the concrete at the open side of the formwork, sealing issues arose and led to epoxy leakage. This complication required additional sealing efforts and underlined the importance of ensuring a sufficiently smooth bonding surface. In future projects, alternative production methods such as vertical casting or grinding the surface could improve surface flatness and reduce leakage risks.

When a leak occurred, sealing the small opening proved challenging, particularly when excess adhesive was above the leak location. To address this, a transparent UV-curing acrylate was injected directly into the leak and immediately cured. However, managing multiple leaks at once proved difficult, requiring significant effort. Future projects should focus on optimizing surface preparation and improving sealing techniques to prevent such issues.

Another insight involved applying a coating layer prior to bonding, which improved adhesion but caused noticeable colour variations in the concrete as the epoxy cured during application of the coating layer. Coating large surfaces, such as the upper side of the hybrid panel, required prolonged application times. As the epoxy batch aged, it became slightly more viscous, reducing its penetration into the concrete and leading to variations in surface colour. Future research into suitable epoxy formulations, application methods, and the potential development of a specifically tailored primer could help achieve a more uniform and aesthetically consistent finish.

Finally, for the spacer tape to function effectively, it must maintain consistent contact with both the glass and concrete to prevent leaks. When the concrete surface was not perfectly flat, achieving full adhesion required applying additional pressure at specific points. In some cases, temporary setups were used to press the glass onto the tape, ensuring initial contact. This highlights the critical need for precise surface preparation and flatness control to ensure optimal sealing performance.

5. Conclusions

The G2C pedestrian bridge represents a pioneering application of glass-to-concrete bonding in fullscale structural design. This case study has demonstrated the feasibility of integrating glass and concrete to create an aesthetically refined and structurally robust pedestrian bridge. The innovative techniques used in this project highlight the potential of hybrid construction for future architectural and engineering applications.

Through the design, production and assembly of this bridge, several key challenges were identified, including handling bonded elements, achieving precise alignment during assembly, and ensuring optimal adhesion on concrete surfaces. Lessons learned from these challenges provide valuable insights for the future development of hybrid glass-concrete structures, particularly regarding surface preparation, bonding methods, and tolerance considerations.

The successful realisation of this project underscores the viability of bonded glass-concrete elements in structural applications, paving the way for further research and practical implementations. The showcased bridge at Glasstec 2024 has sparked interest in the industry, reinforcing the potential of this innovative construction approach. Future work will focus on refining bonding techniques, durability assessments, and exploring broader applications of glass-to-concrete bonding in construction.

Acknowledgements

We would like to express our gratitude to fischerwerke GmbH & Co. KG for providing financial support and the adhesives, to Ergon for supplying the concrete stairs, and to vitroplena bv. for their contributions to the calculations and glass expertise, all of which were essential to the successful realization of this project.

References

Achintha, M.: Sustainability of glass in construction. Elsevier eBooks (2016). https://doi.org/10.1016/b978-0-08-100370-1.00005-6

Narayanasamy, S., Yaragal, S., & Palanisamy, T. Environmental sustainability of waste glass as a valuable construction material – A critical review. Ecology Environment and Conservation. 24, 335–342 (2018)

Udi, U. J., Yussof, M. M., Ayagi, K. M., Bedon, C., & Kamarudin, M. K. A. Environmental degradation of structural glass systems: A review of experimental research and main influencing parameters. Ain Shams Engineering Journal. 14(5), 101970 (2023). https://doi.org/10.1016/j.asej.2022.101970