This paper was first presented at GPD 2025.

Link to the full GPD 2025 conference book: GPD_2025_ConferenceProceedingsBook.pdf

Authors: Pedro Galvez a, Andrea Pilla b, Viviana Nardini c, Chen Fangliang d, Ulli Mueller e

a. Sika Services AG, Switzerland

b. Schüco International KG, Germany

c. Sika Services AG, Switzerland

d. Virtual Construction Lab of Schüco, United States

e. Sika Services AG, Switzerland

Abstract

Sustainability, and more specifically embodied carbon emissions, have become one of the most prominent challenges for the facade industry. Discussions around the topic focus on the global warming potential of materials and their recycled content, whilst efficiency and innovation in design as a way to reduce embodied emissions have not yet received the same level of attention. This article proposes evolved structural design and detailing methods for glass-metal facades that minimize the amount of materials needed to meet their serviceability and structural integrity requirements. The discussion focuses on structural sealant glazing and the composite behavior of glass and frame to resist out of plane loads. The study promotes capitalizing on the inherent contribution of the adhesive connection towards the flexural stiffness of façades and proposes ways of enhancing it for further structural optimization. The selected two-component polyurethane adhesive is characterized at different temperatures to simulate the expected working conditions. The impact of the adhesive connection is assessed through an experimental program consisting of extensive four-point bending tests of representative beam samples and corresponding numerical studies. The article provides an interpretation of the interim results and discusses the potential of the proposed solutions to contribute towards a holistic approach to reduce the global warming potential of building envelopes. Finally, directions for future research needed for practical applications of the proposals are presented and discussed.

Article Information

- Published by Glass Performance Days, on behalf of the author(s)

- Published as part of the Glass Performance Days Conference Proceedings, June 2025

- Editors: Jan Belis, Christian Louter & Marko Mökkönen

- This work is licensed under a Creative Commons Attribution 4.0 International (CC BY 4.0) license.

- Copyright © 2025 with the author(s)

1. Introduction

Structural sealant glazing (SSG) is a well-established bonding technology in the building façade industry, where glass units are bonded to metal frames by means of adhesion. Since its emergence in 1965 and subsequent regulation by ETAG002 and ASTM C1401 (Alcaine, et al., 2024), SSG has gained significant popularity for its clean, flush appearance, transforming the look of modern cities (J.T.Ma, 2010). It has proven to be a durable and structurally reliable bonding technology (P.Vandereecken, 2014), able to replace other glass retention types, primarily captured glazing.

A curtain wall is a non-structural cladding system that transfers loads acting on the cladding to the primary support structure through its connections (The Institution of Structural Engineers, 2020). Currently, when evaluating the behaviour of SSG systems under loads, industry practice assumes that all external loads are carried solely by the framing, without accounting for any combined or composite structural interaction between the glazing and the frame. While this assumption reduces calculations complexity and streamlines trade coordination, it often leads to the overdesign of the façade substructure.

In a world where building sustainably is an increasingly critical challenge, the façade industry has made significant progress in reducing the global warming potential of materials by utilizing greener primary energy sources and incorporating high recycled content. While maximizing recycling is essential, it is becoming clear that it alone is not sufficient to meet future targets, primarily due to the growing global demand for materials (European Aluminium, 2022). Therefore, it is imperative to explore new innovations that optimize and reduce material usage in curtain wall systems.

Previous studies have demonstrated that glass panels linearly bonded to profiles using high-strength adhesives can achieve composite action under flexural loads and exhibit significant post-fracture strength. (S.Nhamoinesu, 2014) and (C.Pascual S. M., 2019) investigated medium-scale (700 mm×300 mm) and large-scale (3500 mm×1500 mm) steel-glass composite units subjected to out-ofplane loads. These units consisted of two glass panes with rectangular steel profiles positioned either along their longitudinal edges or along both their longitudinal and transverse edges.

Similarly, (C.Pascual J. M., 2017) (M.Gargallo, 2021) tested composite sandwich panels composed of glass face sheets adhesively bonded to a centred core profile made of glass fibre-reinforced polymer (GFRP). Their findings showed that using moderately stiff adhesives in GFRP-glass sandwich beams resulted in a composite action (in terms of deflection) of 95%, compared to just 16% for similar beams bonded with conventional low shear modulus structural silicones.

This study presents and discusses the results of an extensive experimental program conducted to validate the advanced structural design concept, the 'Minimal Wall,' previously introduced in (S.Trifonov, 2024). Applied to structurally glazed unitized façades, this concept considers the partial composite behaviour enabled by adhesive connections and aims to minimize the aluminium usage. This is achieved by enhancing shear transfer between glass and metal through a secondary adhesive applied locally at the unit corners.

The secondary rigid adhesive is introduced locally, while the unit, primarily bonded with conventional structural silicone, is evaluated for safety at ultimate limit states with the same level of conservatism as current practise. The proposed rigid adhesive is intended solely for structural optimization in terms of serviceability limit states, which is typically the critical factor in sizing the framing members.

The experimental studies conducted includes four-point bending tests on representative beam samples to assess impact of the adhesive connection, as well as material characterization and compatibility studies of the rigid adhesive used in the beam tests.

2. Four-point bending test

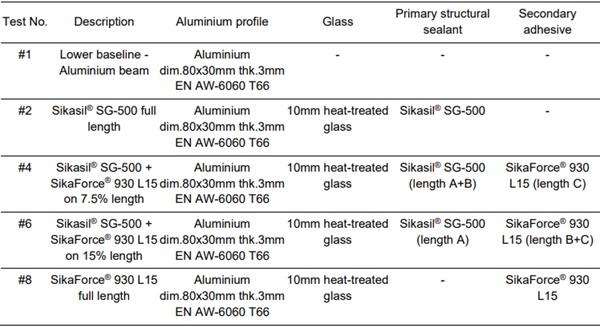

As extensively documented in (S.Trifonov, 2024) an extensive experimental study was conducted to evaluate the feasibility of the proposed concept and evaluate the contribution of the partial composite behaviour. The campaign involved testing forty beam specimens subjected to four-point bending. The specimens represented primary members of a unit, e.g. a vertical frame, with their tributary glass width, subjected to bending due to out-of-plane load.

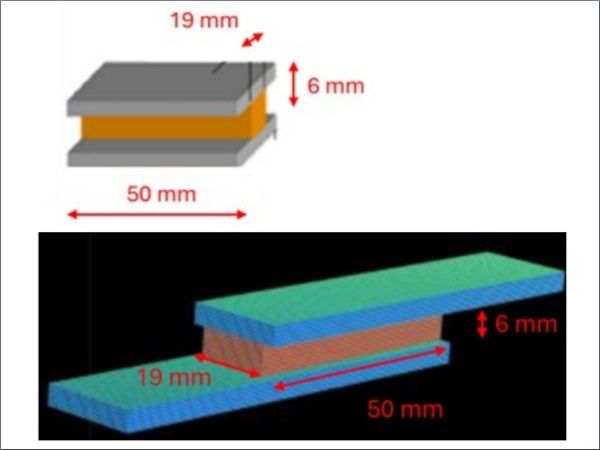

The specimens were categorized into different series, varying in terms of sealant type and the length of the secondary rigid adhesive. Series #1 specimens were a simple rectangular hollow section beams without glass or adhesive, representing the conventional structural design approach. This series represents the reference baseline against which all other configurations were compared. An overview of the samples is provided in Table 1.

Table 1: Summary of the specimens tested.

The samples were designed to be symmetric and as simple as possible, to ensure that the test focused exclusively on the composite behaviour of the different beam configurations without the effect of any “polluting” factors, e.g. eccentricities, bonding strips etc. The size of the aluminium section and the tributary glass component were selected to have broadly the same stiffness ratio as a real life SSG member.

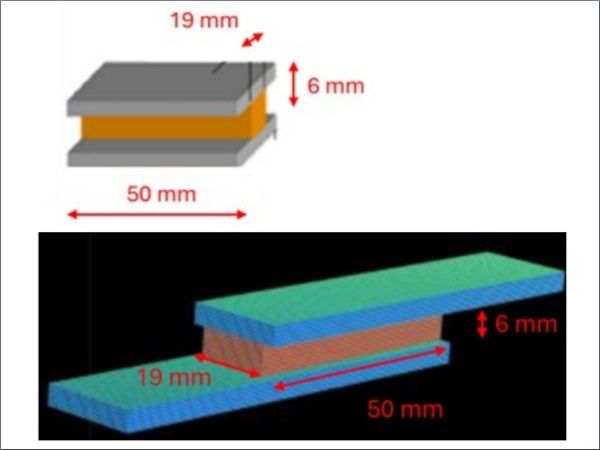

In all configurations, the primary structural silicone and the secondary adhesive, have an equal centred bite of 19mm bite and a thickness of 6mm.

All beam specimens were tested under four-point bending following the recommendations set out in (ASTM, 2016) and the deflection at the midspan was measured with a linear variable differential transformer (LVDT) with a 50mm spring.

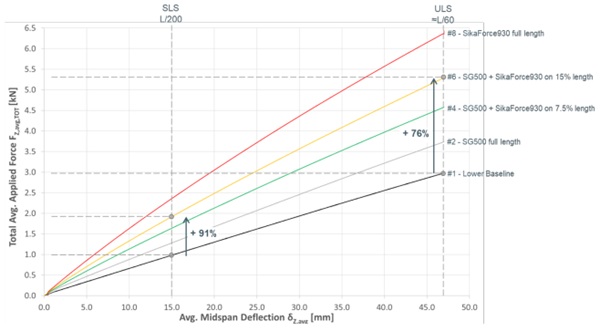

The load-deflection curves for all test series along with detailed results, were presented in (S.Trifonov, 2024). The average load-mid-span deflection curves for the analysed sample series, shown in Figure 2, indicate that varying the length and the material properties (i.e. shear modulus) of the adhesive at the beam ends effectively influences the overall stiffness of the hybrid assemblies.

Taking into account the inherent shear transfer provided by the standard structural silicone can bring to an increase of more than 20% in the applied load required to achieve the same deflection as the baseline. Sample series #6 with SikaForce®930 over 450mm (15% of the beam length) at each end of the beam and standard structural silicone in the remaining joint demonstrated an average improvement of 91% in applied force at the serviceability limit state compared to the baseline.

3. Material selection

The selection of a suitable material for structural bonding applications is crucial to ensuring the longterm durability, reliability, and safety of the assembled components. In this case, a two-component semi-flexible structural polyurethane adhesive has been chosen due to its superior mechanical properties, good adhesion to a variety of substrates, and outstanding resistance to environmental factors (Galvez, Lopez de Armentia, Abenojar, & Martinez, 2020).

Polyurethane adhesives exhibit excellent behaviour, including hight strength and flexibility, making them ideal for load-bearing applications. Their ability to distribute stress uniformly across bonded joints ensures enhanced structural integrity compared to other traditional mechanical joining methods (Galvez, et al., 2017).

This adhesive technology demonstrates strong adhesion to a variety of materials commonly used in facade construction, including aluminum, steel, glass, and composite panels. The ability to bond dissimilar materials (Galvez, Abenojar, & Martinez, Durability of steel-CFRP structural adhesive joints with polyurethane adhesives, 2019) is a significant advantage in modern facade designs (Gonzalez, 2023).

Unlike brittle adhesives such as epoxies, polyurethane adhesives maintain a degree of flexibility after curing. This property is essential in facade applications, where thermal expansion, wind loads, and other dynamic stresses can cause movement in bonded joints (Alcaine, et al., 2024).

Facade elements are exposed to various environmental conditions, including temperature fluctuations, humidity, and chemical pollutants. Structural polyurethane adhesives offer superior resistance to these factors, ensuring long-term performance with minimal degradation (Smith & Johnson).

The two-component adhesive systems allow for controlled curing times, facilitating efficient assembly and installation processes. It can be applied using automated dispensing equipment, ensuring consistent and high-quality bond formation.

By eliminating the need for mechanical joining, polyurethane adhesives contribute to weight reduction in facade panels, reducing the amount of material needed, creating more efficient and sustainable systems. Additionally, they provide seamless bonding, improving the overall aesthetic appeal of the structure.

4. Material characterization – Experimental procedure

This section presents the tests carried out to obtain the material characterization of the referred twocomponent structural polyurethane adhesive developed by Sika, hereinafter referred to as SikaForce®- 930 L15. The characterization includes:

- Tensile and shear mechanical tests performed on H-specimens at different temperatures: RT, -20ºC, 40ºC, 55ºC and 80ºC.

- Tensile tests according to ISO 527 at different temperatures RT, -20ºC, 40ºC, 55ºC and 80ºC.

- Determination of Poisson’s ratio at different temperatures: RT, -20ºC, 40ºC, 55ºC and 80ºC.

- Fatigue performance assessment according to EOTA ETAG 002, section 5.1.4.6.5.

- Tensile mechanical properties of SikaForce®-930 L15 after curing and after artificial aging.

- Compatibility tests with Sikasil® SG-500 and with other elements of the system.

4.1. Tensile and shear tests on H-specimens

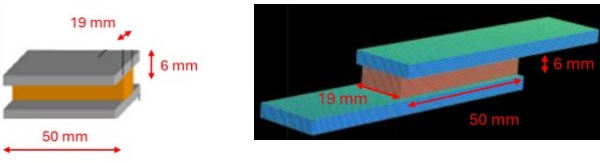

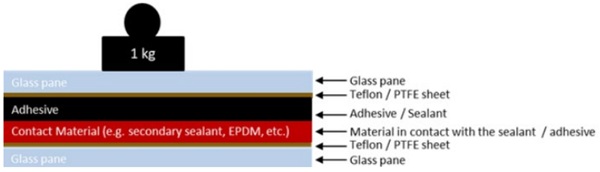

H-shaped specimens were used to evaluate the mechanical performance of the SikaForce®-930 L15 joints under tensile and shear loading conditions. The H-specimens were manufactured using specifically designed teflon molds ensuring the following joint dimensions: 19 mm x 6 mm x 50 mm (width x thickness x length). These joint dimensions are fixed and defined by the system. Developed samples for tensile and shear tests are shown in Figure 1:

SikaForce®-930 L15 is a two components adhesive. The curing process is produced by chemical reaction when both components are mixed. The specimens were stored for 28 days at laboratory conditions (23°C and 50% relative humidity), before testing, to ensure the full curing of the adhesive. Both tensile and shear tests were carried out at different temperatures (RT, -20ºC, 40ºC, 55ºC and 80ºC) using an universal testing machine at a displacement rate of 5 mm/min.

4.2. Tensile tests according to ISO 527

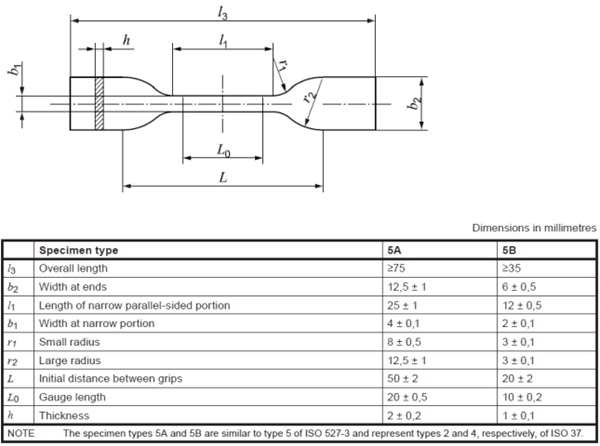

Dumbbell / dog-bone specimens according to ISO 527-2 Type 5A were manufactured to evaluate the mechanical performance of the SikaForce®-930 L15 adhesive. Manufactured samples are shown in Figure 2. The specimens were stored for 28 days at laboratory conditions (23°C and 50% relative humidity), before testing, to ensure the full curing of the adhesive. Tensile tests were carried out at different temperatures (RT, -20ºC, 40ºC, 55ºC and 80ºC) using an universal testing machine at a displacement rate of 200 mm/min.

4.3. Poisson ratio

Dumbbell / dog-bone specimens according to ISO 527-2 Type 5A were manufactured to obtain the poisson ratio of the SikaForce®-930 L15 adhesive. Manufactured samples are shown in Figure 2. The specimens were stored for 28 days at laboratory conditions (23°C and 50% relative humidity), before testing, to ensure the full curing of the adhesive. Tests were carried out at different temperatures (RT, -20ºC, 40ºC, 55ºC and 80ºC) following CQP055-1 (Sika internal Corporate Quality Procedure) using digital image correlation (DIC) recording transverse and axial strains during tensile testing.

4.4. Fatigue performance assessment according to EOTA ETAG 002

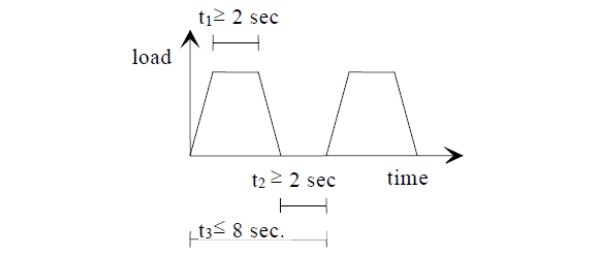

Fatigue performance was assessed according to EOTA ETAG 002, Section 5.1.4.6.5. Lap shear specimens with joint dimensions 25 mm x 12 mm x 2 mm (width x overlap x thickness) were manufactured to evaluate the fatigue performance assessment of the SikaForce®-930 L15. Reference and fatigued specimens were stored for 28 days at laboratory conditions (23°C and 50% relative humidity), before testing, to ensure the full curing of the adhesive. Reference and fatigued specimens were tested at RT using an universal testing machine at a displacement rate of 18 mm/min, following DIN 17460. The fatigue test was conducted by applying cyclic shear loading between 10% and maximum 100% of the pre-defined dynamic shear strength (τDes = 1.6 MPa) of the adhesive with a cycle time of 6 seconds (Figure 3), as follows:

- 100 times from 0.1 τDes to the design stress τDes

- 250 times from 0.1 τDes to 0.8 x the design stress τDes

- 5000 times from 0.1 τDes to 0.6 x the design stress τDes

4.5. Tensile mechanical properties of SikaForce®-930 L15 after curing and after artificial aging

To evaluate the mechanical performance of the SikaForce®-930 L15 after aging, Dumbbell / dog-bone specimens according to ISO 527-2 Type 5A were manufactured and subjected to the following combination of aging conditions:

- B: 7 days at 23°C and 50% relative humidity.

- C: 7 days in full Immersion in deionized water at 23ºC.

- F: 1 day at 80ºC.

- G: 2 hours at 23°C and 50% relative humidity.

- L: 7 days in Cataplasma storage at 70°C fully saturated humidity (98% r.h.).

- A: 1 day at 23°C and 50% relative humidity. Both reference and aged specimens were cured for 28 days at 23°C and 50% relative humidity before testing and before being subjected to aging cycles respectively (BCFGLA).

4.6. Compatibility tests between SikaForce®-930 L15 and Sikasil® SG-500

To evaluate the compatibility between SikaForce®-930 L15 and Sikasil® SG-500, a series of mechanical tests were conducted. The objective was to determine potential chemical interactions, adhesion strength, and durability of the adhesive joint when both SikaForce®-930 L15and Sikasil® SG500 are in contact.

Dumbbell / dog-bone specimens according to ISO 527-2 Type 5A were manufactured and tested following CQP 593-4 (Sika internal Corporate Quality Procedure). Specimens were stored for 6 weeks at 70 °C in close contact. They were then cooled down to laboratory controled conditions (23°C and 50% relative humidity) for at least 24 hours before assessing the mechanical values. Reference values were obtained from specimens subjected to the same storage conditions (6 weeks at 70 °C) but without contact between tested materials.

5. Material characterization – Results

5.1. Tensile and shear tests on H-specimens

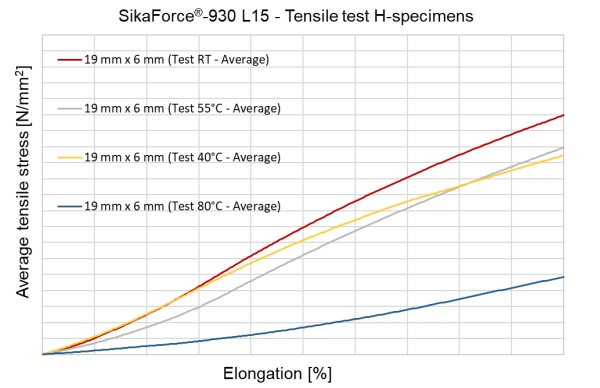

Tensile tests from H-Specimens were carried out at different temperatures (RT, -20ºC, 40ºC, 55ºC and 80ºC) to assess temperature sensitivity of the specific 19 mm x 6 mm (bite x thickness) adhesive joint. As showed in Figure 7, the material becomes more elastic with increasing temperature while is quite stable and similar at RT, 40ºC and 55ºC.

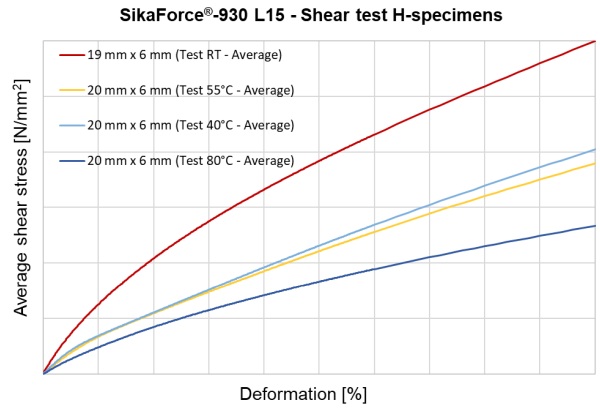

Shear tests from H-Specimens were carried out at different temperatures (RT, -20ºC, 40ºC, 55ºC and 80ºC) to assess temperature sensitivity of the specific 19 mm x 6 mm (bite x thickness) adhesive joint. As showed in Figure 8, the material becomes more elastic with increasing temperature while is more rigid as the temperature decreases.

5.2. Tensile tests according to ISO 527

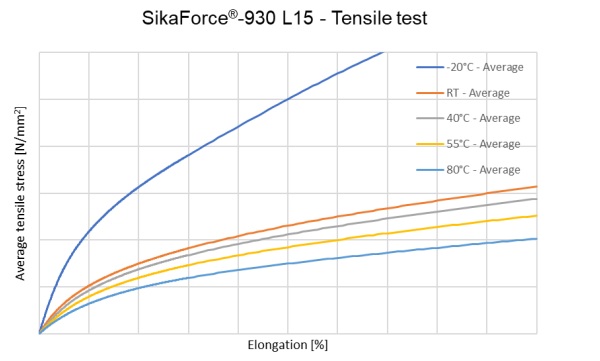

Tensile tests were carried out at different temperatures (RT, -20ºC, 40ºC, 55ºC and 80ºC) to assess temperature sensitivity of the adhesive. As showed in Figure 9, the material becomes more rigid as the temperature decreases while the material becomes more elastic with increasing temperature. This is a well known behaviour in polyurethane adhesives and should be aligned with the system requirements.

5.3. Poisson ratio

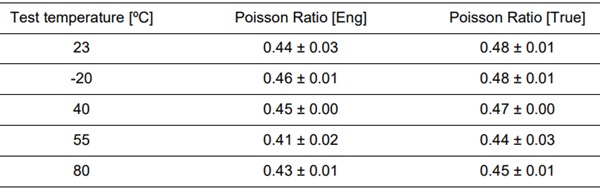

Poisson’s ratio was measured from dumbbell / dog-bone specimens according to ISO 527-2 Type 5A at different temperatures (RT, -20ºC, 40ºC, 55ºC and 80ºC) to assess temperature sensitivity of the adhesive. Engineering and true values of the Poisson ratio are showed in Table 2.

Table 2: Poisson ratio of SikaForce®-930 L15 measured at different temperatures.

5.4. Fatigue performance assessment according to EOTA ETAG 002

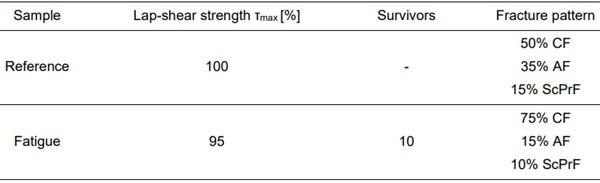

Fatigue performance was assessed according to EOTA ETAG 002, Section 5.1.4.6.5. The test was conducted by applying cyclic shear loading between 10% and maximum 100% of the pre-defined dynamic shear strength (τDes = 1.6 MPa) of the adhesive with a cycle time of 6 seconds. Results of the reference specimens and the fatigued specimens are shown in Table 3:

Table 3: Performance of SikaForce®-930 L15 after fatigue compared to reference samples.

As can be oberved in Table 3, all the fatigued specimens (10) survived to the fatigue test showing very similar τmax values compared to the reference samples. SikaForce®-930 L15 shows a very good performance under fatigue loads according to EOTA ETAG 002, Section 5.1.4.6.5.

5.5. Tensile mechanical properties of SikaForce®-930 L15 after curing and after artificial aging

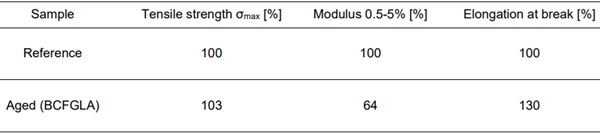

Tensile mechanical properties of SikaForce®-930 L15 were evaluated after curing at RT for 28 days, and after being subjected to artificial aging as stated in the section 4.5 of this paper. Results are summarized in the Table 4 of this document, showing the deviation to reference (100%) in the aged sample line.

Table 4: Tensile mechanical properties of SikaForce®-930 L15 after curing and after curing + artificial aging (BCFGLA) obtained from tensile test on dumbbell / dog bone specimens.

Aged samples show very similar values (+3%) in term of maximum tensile strength (σmax) compared to the reference ones. On the other side, SikaForce®-930 L15 becomes more elastic after aging, showing a reduction of 36% in the modulus (0.5-5%) and showing an increment of 30% in the elongation at break compared with the reference specimens.

5.6. Compatibility tests between SikaForce®-930 L15 and Sikasil® SG-500

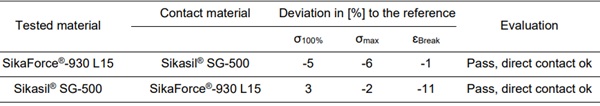

To evaluate the compatibility between SikaForce®-930 L15 and Sikasil® SG-500, tensile mechanical properties were evaluated following Sika internal procedures (CQP 593-4). Results are summarized in Table 5.

Table 5: Compatibility tests of SikaForce®-930 L15 and Sikasil® SG-500.

The limit for the deviation for Sikasil® SG-500 and SikaForce®-930 L15 materials in contact to others is σ100% ≤ 15%, following CQP593-4, based on industry standards. Maximum deviation of -5% was found on the SikaForce®-930 L15 when it is in contact with Sikasil® SG-500, confirming the good compatibility between both products.

6. Conclusions

This study focuses on the material characterization and performance evaluation of the two-component structural polyurethane adhesive SikaForce®-930 L15, previously used to fabricate glass-aluminium samples tested in four-point bending.

Tests conducted on specimens with SikaForce®-930 L15 applied over 450 mm on each side of the beam, combined with standard structural silicone in the remaining joint, demonstrated up to a 91% improvement in out-of-plane stiffness compared to non-composite members using the same crosssections of materials.

Understanding the mechanical properties of this polyurethane adhesive, also after exposure to different temperatures and fatigue cycles, along with its compatibility with structural silicone, is crucial for ensuring the long-term durability, reliability, and safety of assembled components. The knowledge of these design parameters also enables accurate structural analysis of the assembly through finite element modelling.

Tensile and shear tests on H-specimens at different temperatures showed consistent and expected mechanical behavior, indicating the adhesive's stability under varying thermal conditions. Similarly, tensile tests carried out according to ISO 527 confirmed these trends, providing further confidence in the adhesive's structural performance.

Measurements of the Poisson ratio at different temperatures revealed values consistently around 0.44, which aligns with typical behavior of polyurethane adhesives. This value reflects the material’s elastomeric nature, offering a good balance between stiffness and flexibility—essential characteristics for adhesives used in dynamic building envelope systems. Such Poisson ratio values are advantageous in accommodating differential movements between bonded elements while maintaining mechanical integrity.

Fatigue resistance was assessed in accordance with EOTA ETAG 002 guidelines. All ten tested samples withstood the imposed fatigue loading, with only a minor (5%) reduction in maximum shear strength, confirming excellent long-term performance under cyclic stress conditions.

The adhesive's resistance to environmental factors was evaluated through artificial aging tests, which showed that the tensile mechanical properties remain stable, confirming the adhesive’s resilience to moisture, temperature variations, and other atmospheric agents. This behavior is consistent with the known resistance of polyurethane adhesives to hydrolytic degradation and environmental aging, further supporting their applicability in exposed façade applications.

Compatibility tests between SikaForce®-930 L15 and Sikasil® SG-500 revealed only minor reductions in mechanical properties, indicating a favourable interaction and no significant adverse effects. This result supports the adhesive’s integration into hybrid bonding systems where multiple adhesive technologies are used concurrently. Therefore, the material shows strong potential for the Minimal Wall concept, further enhancing the composite behaviour between glass and aluminium and enabling considerable material savings while maintaining overall stiffness and strength.

Overall, the conducted tests have defined and validated the mechanical and environmental performance limits of this two-component structural polyurethane adhesive. The results confirm its high suitability for the demands of the Minimal Wall concept, offering a robust, durable, and compatible bonding solution for advanced façade designs.

The next steps toward implementing the Minimal Wall concept in façade buildings involve conducting an additional testing campaign on full-scale façade units to assess their performance under wind loads and temperatures relevant to typical façade applications.

References

Alcaine, J., Forwood, E., Galvez, P., Lenk, P., Mueller, U., & Nardini, V. (2024). Holistic Review of the Permanent Shear Deformation Effects on Structural Silicone Joints in SSG Façade Systems. Challenging Glass Conference Proceedings, 9.

ASTM. (2016). Standard Practice for Determining Sandwich Beam Flexural and Shear Stiffness. C.Pascual, J. M. (2017). Adhesively-bonded GFRP-glass sandwich components for structurally efficient glazing applications. Composite Structure, 560-573.

C.Pascual, S. M. (2019). The flexural response of large scale steel-framed composite glazing panels. Glass Structures & Engineering 4.

European Aluminium. (2022, October 24). Our Vision 2050 for the aluminium industry. Opgehaald van https://european-aluminium.eu/blog/vision2050/

Galvez, P., Abenojar, J., & Martinez, M. (2019). Durability of steel-CFRP structural adhesive joints with polyurethane adhesives. Composites Part B, 165, 1-9.

Galvez, P., Lopez de Armentia, S., Abenojar, J., & Martinez, M. (2020). Effect of moisture and temperature on thermal and mechanical properties of structural polyurethane adhesive joints. Composite Structures, 247, 112443.

Galvez, P., Quesada, A., Martinez, M., Abenojar, J., Boada, M., & Diaz, V. (2017). Study of the behaviour of adhesive joints of steel with CFRP for its application in bus structures. Composites Part B, 129, 41-46.

Gonzalez, H. (2023). Structural adhesive technologies in modern facade engineering. Construction Materials Journal, 77(2), 88-101.

J.Alcaine, P. E. (2020). Structural Silicone Glazing – Design & Modelling. Challenging Glass 7 - Conference on Architectural and Structural Applications of Glass. Ghent: Belis, Bos & Louter.

J.Nielsen, J. P. (2010). Simulation of residual stresses at holes in tempered glass: A parametric study. Materials and Structures/Materiaux et Constructions, 947-961.

J.T.Ma, A. (2010). Structural sealant glazing - an advanced glass fixation system used in constructing safe and green building facades. 2010 Hong Kong Advance Facade Engineering and Technology Conference. Hong Kong.

M.Gargallo, B. A.-S. (2021). Material Selection and Characterization for a Novel Frame-Integrated Curtain Wall. Advances in Construction and Building Materials 14, 1896.

M.Overend, S. J. (2013). Structural performance of bolted connections and adhesively bonded joints in glass structures. Journal of Structural Engineering 139, 04013015.

P.Vandereecken, M. M. (2014). Durable high design strength in glass curtain wall. Challenging Glass 4 & COST Action TU0905 Final Conference.

S.Nhamoinesu, M. V. (2014). The mechanical performance of adhesively bonded steel-glass composite panels – Medium-scale tests and numerical models. Challenging Glass 4 & COST Action TU0905 Final Conference (pp. 269-276). Lausanne, Switzerland: Taylor & Francis Group, London.

S.Trifonov, A. F. (2024). The Minimal Wall: A composite approach in the design of glass-aluminium facades to minimise embodied carbon emissions. Challenging Glass Conference.

Smith, L., & Johnson, M. (sd). Thermal and mechanical stability of structural adhesives for extreme environments. International Journal of Adhesion Science, 45(3), 567-580.

The Institution of Structural Engineers. (2020). Structural aspects of cladding. London: The Institution of Structural Engineers.

V.Silvestru, G. F. (2019). Adhesively bonded glass-metal façade elements with composite structural behaviour under in-plane and out-of-plane loading. Engineering Structures 200.

W.Laufs, G. (1999). Stress distribution in thermally tempered glass panes near the edges, corners and holes. Part 1. Temperature distributions during the tempering process of glass panes. Glass Science and Technology - Frankfurt am Main- 72, 7-14.