Date: 13 November 2025

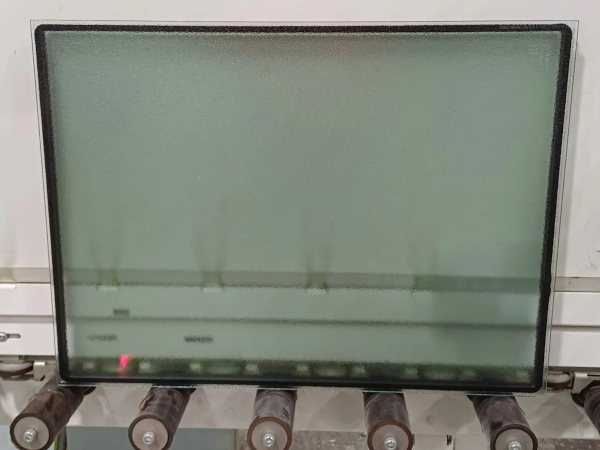

It enables manufacturers to verify insulating gas, like argon, concentration during the production process without breaking the sealed unit or slowing down the line.

What Is Sparklike Laser Integrated?

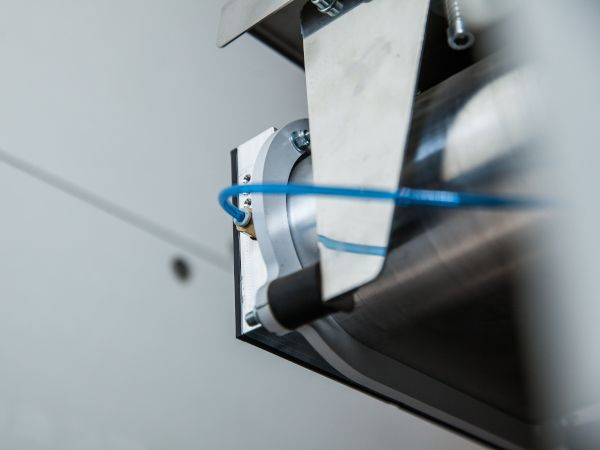

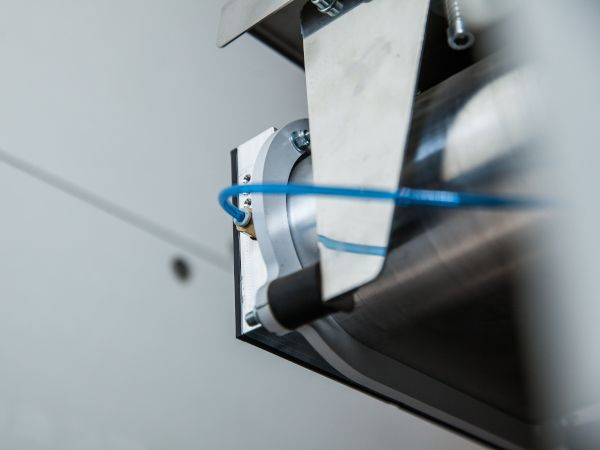

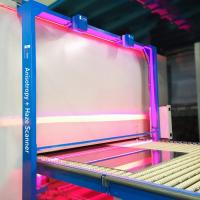

Sparklike Laser Integrated is part of Sparklike’s advanced range of laser-based gas measurement devices. Unlike Sparklike Handheld or Sparklike Laser Portable options, this system is installed on the IG line. It automatically tests the gas fill rate of every unit that passes through the measurement station, ensuring continuous quality control without manual steps.

The device uses TDLAS (Tunable Diode Laser Absorption Spectroscopy), a laser-based technology that measures gas concentration through the glass. It is suitable for double and triple glazed IGUs, including most coated or laminated glass.

How Does It Work?

Once installed into the production line, Sparklike Laser Integrated functions as a turnkey quality control system:

- It scans each IGU using laser technology to analyze the concentration of argon or krypton gas.

- Measurements are done non-invasively, through the glass, without compromising the unit’s structure.

- The results are automatically stored in a database and can be connected to ERP or MES systems.

This process provides real-time data for every unit, allowing manufacturers to monitor performance, ensure compliance, and adjust production settings if needed.

Why Is It Beneficial?

1. Complete Inline Quality Control

Sparklike Laser Integrated allows you to verify the gas content of every single unit, not just random samples. This improves product consistency and reduces the risk of customer claims or failed inspections.

2. Non-Destructive Testing

Traditional methods like gas chromatography require breaking or piercing the seal. Sparklike’s solutions keeps every tested IGU intact and sellable.

3. Works With Advanced IG Structures

The system is capable of measuring gas concentration in IGUs with most coatings, laminations, and triple glazing.

4. Production Optimization

When you can see real-time measurement trends, you can optimize your gas press settings and filling processes reducing waste and increasing yield.

5. Traceability and Compliance

Measurement data is logged, helping you meet internal and regulatory requirements with documented proof of quality.

Preparing for Integration: What to Consider

Installing Sparklike Laser Integrated is a collaborative process, guided by Sparklike experts. Here’s what’s typically needed:

- Line Layout Planning

A Sparklike technician will help assess the ideal measurement point.

- IGU Specifications

Details on IGU types (thickness, gas, coatings, sizes) are used to configure the system accurately.

- Software and Connectivity

The system can operate stand-alone or be integrated into your production network. The connection requirements should be reviewed early.

- Operator Training

Basic user training is included, along with documentation and ongoing support. The system is low-maintenance and easy to operate once installed.

- Installation Timeline

Installation and commissioning typically take 1–2 weeks. Sparklike ensures smooth setup and transition without disrupting production.

A Smarter Way to Guarantee Performance

Sparklike Laser Integrated brings automated quality control into the production flow helping IG manufacturers reduce risks, improve product reliability, and streamline operations.

If your production involves high volumes, coated or laminated glass, or strict performance requirements, this solution offers a clear advantage. It’s the only non-invasive technology on the market that enables continuous argon and krypton gas measurement for complex IGUs.

Contact Sparklike for more information à https://sparklike.com/en/contact-us/

600450

600450

Add new comment