Date: 27 January 2026

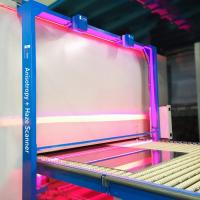

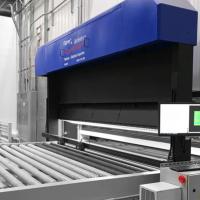

Modern insulating glass production has become highly automated also in noticing IGU defects. Advanced visual inspection systems now detect scratches, roller wave, optical distortion, anisotropy, and spacer defects with impressive precision. Companies such as Viprotron and Softsolution have raised industry expectations for what visual quality control can achieve.

Yet many of high-impact performance issues in IGUs do not appear on the surface. Gas fill problems, leaks, and weak seals often go unnoticed. They only appear when insulation fails, windows fog, performance tests fail, or warranty claims arise.

This is where many manufacturers have found Sparklike to be an essential part of their IGU quality strategy. Real customer cases demonstrate that measuring invisible issues allows companies to optimize gas filling processes, verify seal integrity, and maintain consistent IGU performance.

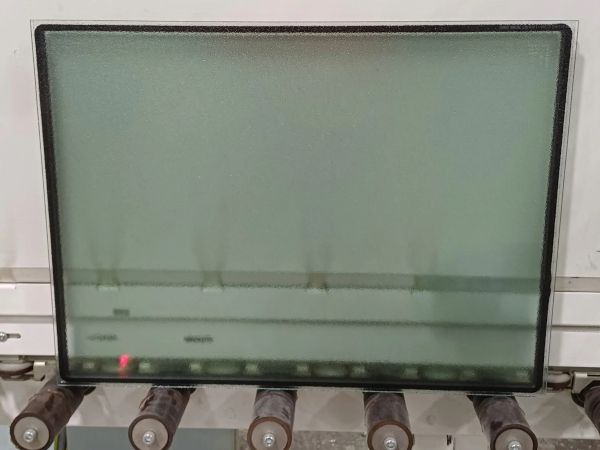

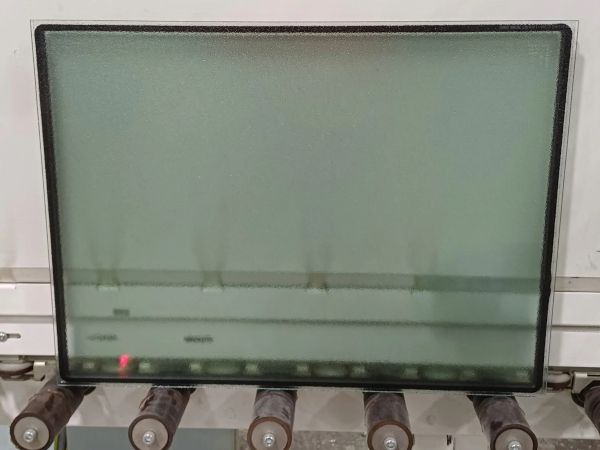

Visible IGU Defects: What Automated Systems Catch

Visual inspection systems are excellent at detecting surface-level and assembly-related issues. These include:

Scratches, dirt, and inclusions

Contaminants or surface damage introduced during handling, cutting, washing, or assembly.

Edge defects and chipping

Produced during cutting or grinding. These issues can reduce durability and increase breakage risk.

Optical distortions and roller wave

Typical in tempered glass, causing uneven reflections. Systems from Viprotron or Softsolution detect and quantify these defects.

Anisotropy

A visual effect from stress patterns created during tempering. Now widely monitored to ensure consistent visual quality.

Misalignment or spacer defects

Visible mechanical issues that may lead to air leakage, stress, or premature failure of the unit.

These systems ensure an IGU looks correct before it leaves the production line. But appearance is only one part of quality and not the only part that determines insulation performance.

The Critical Defects No Visual System Can Detect

Incorrect Gas Fill Rates — Invisible but Immediately Impactful

Even a flawless-looking IGU can be significantly underfilled with argon or krypton.

Many manufacturers first discovered this hidden defect after using Sparklike devices to check their production. Some found:

- IGUs filled to only 50–60% of target levels

- variations between operators and shifts

- differences in triple-glazed cavities

- temperature-related filling inconsistencies

These findings are described in Sparklike’s article:

How to Monitor Gas Filling Equipment for Insulating Glass Units

Manufacturers used Sparklike devices to check their gas press performance. This helped them change their filling parameters. As a result, they achieved more consistent U-values and reduced failed energy tests.

This is one of the most common hidden defects Sparklike helps manufacturers identify.

Gas Leakage Over Time — Environmental Stress Creates Invisible Failures

A unit can pass all factory checks yet lose gas months later. In a test, a Sparklike customer checked how insulating glass units keep argon gas. They also tested how these units react to changes in latitude. Watch the entertaining video on argon retention in different latitudes.

This showed that long-term performance cannot be guaranteed by visual inspection alone and that gas retention must be validated.

Seal Failures — Hidden Weaknesses That Are Hard To See

Even when an insulating glass seal looks intact, it may not be performing as intended. Visual inspection cannot show whether the hermetic seal is still maintaining the correct gas concentration inside the IGU.

Sparklike devices measure the noble gas content (such as argon or krypton) as a percentage. By taking successive measurements from the same unit over time, quality teams can track how the gas concentration changes.

If the readings show a quick drop in gas level, this may indicate that someone has broken the IGU seal. No longer keeping the expected insulation performance.

Some gas loss is normal over the life of an IGU. However, fast changes are a warning sign that might go unnoticed.

FAQ: Would I be able to use a Sparklike device to determine whether the IGU seal has failed?

A practical example of checking seal integrity is in the case of “Weihai Blue Star.” They verify the seal integrity of insulating glass using a Sparklike handheld device.

In this test, Weihai Blue Star used the Sparklike Handheld. They showed how it works in tough conditions.

The insulated glass units were placed in a water tank. After that, they measured the gas concentration. The results showed that the gas fill level stayed stable. This clearly proved that the seal and the IGU construction worked as expected.

Non-invasive gas measurement helps manufacturers check seal performance and gas retention without opening the unit. This gives assurance that visual inspection alone cannot provide.

Thermal Performance Degradation — A Silent, Slow Decline

Insulating glass units are designed to deliver long-term thermal performance, but their behaviour over time is not static. Environmental factors like temperature changes, moisture, and UV exposure slowly impact gas retention and sealants. This leads to higher U-values and more demand for heating and cooling.

The article “Degradation of Insulating Glass Units – How Sparklike Helps Thermal Performance Monitoring” shares findings from a 2023 study. The title of this study is “Degradation of Insulating Glass Units: Thermal Performance, Measurements, and Energy Impacts.” The study shows that current durability tests and energy models often do not show how IGUs age in real life. Seal failures and gas leaks can greatly affect energy use over time.

Sparklike Laser Portable™ offers a practical way to monitor this degradation in the field. It provides non-invasive, in-situ measurement of argon or krypton levels in IGUs. With portable use and ±2% precision, it enables professionals to:

- detect early performance loss caused by gas leakage or sealant wear,

- plan timely retrofits or replacements to maintain energy efficiency, and

- supply accurate data for lifetime energy modeling and energy-efficiency assessments.

In this way, Sparklike technology helps bridge the gap between laboratory durability tests and the long-term thermal performance of IGUs in buildings.

Sparklike customer stories on-site:

On-site Insulating Glass Inspection for Gas Fill In a Well-known Building

Why These Invisible Defects Matter More Than Ever

The industry faces growing pressures:

- stricter energy requirements

- mandatory quality documentation

- increased warranty expectations

- demand for traceable quality control data

- sustainability and IGU lifecycle considerations

In this environment, relying solely on what can be seen is not enough. Manufacturers must validate gas fill accuracy, seal reliability, and long-term performance.

How Sparklike Completes the IGU Quality Assurance Chain

Visual inspection ensures that the IGU meets visible and structural quality requirements. Sparklike complements this by verifying gas fill accuracy which is the key performance factor that cannot be assessed visually. Manufacturers use Sparklike Handheld, Laser Portable, and Laser Integrated to:

- verify gas fill accuracy during production

- monitor the stability of gas filling equipment

- identify and fix hidden sealing issues

- analyze field complaints objectively

- verify IGUs after environmental tests or transport

- support EN 1279, ASTM and other compliance

- protect reputation and minimize warranty claims

Many manufacturers report the same experience: once they start measuring gas, they uncover quality issues they never knew existed and immediately reduce long-term risk.

Combining Visible and Invisible QC for Complete Reliability

A complete quality control strategy must integrate:

Visible Defects: detected by visual inspection systems

- scratches

- dirt

- inclusions

- edge defects

- chipping

- roller wave

- optical distortion

- anisotropy

- spacer alignment issues

Invisible Performance Defects: detected by Sparklike

- underfilled units

- gas leakage

- seal microfailures

- performance degradation

- environmental stress weaknesses

- transportation-related gas loss

By addressing both visible and non-visible IGU defects, manufacturers can ensure that insulating glass units meet all required visual, structural, and thermal performance criteria.

Conclusion: Ensuring Complete IGU Quality

Visual inspection systems identify the visible defects that affect appearance, durability and assembly quality. These checks are an essential part of insulating glass production.

However, many performance-related issues cannot be seen. Incorrect gas fill levels, gas leakage and seal failures do not leave visible signs immediately, yet they directly affect insulation performance and long-term reliability. These issues can be detected by measuring the gas concentration inside the IGU.

By adding non-invasive gas measurement to quality process, manufacturers can confirm gas fill accuracy, verify seal performance and monitor gas retention. This supports compliance with standards and helps reduce warranty claims related to insulation performance.

When manufacturers combine visual inspection with gas measurement, they gain a complete view of IGU quality. This ensures that each unit meets the required visual, structural and thermal performance levels throughout its service life.

Contact Sparklike to discuss your gas measurement needs.

600450

600450

Add new comment