Date: 16 February 2026

Reliable energy performance in insulating glass units depends not only on design and materials, but also on what is sealed inside the unit. While argon gas significantly improves thermal insulation compared to air, its benefits can only be ensured if the gas content is accurately measured and verified.

Xinruineng Glass Technology Co., Ltd. understands this challenge well. As building energy-efficiency requirements continue to rise in China, air-filled insulating glass units are no longer an option. Due to air’s relatively high thermal conductivity, they cannot deliver the insulation performance required by modern standards. Argon-filled insulating glass units, with significantly lower thermal conductivity, have therefore become essential for achieving reliable thermal performance and compliance.

Argon-Filled Units: Why Fill Rate Matters for Reliable Insulation Performance

The Need for Argon Measurement of IGUs

Chinese national standards require that insulating glass units maintain an initial argon concentration of at least 85%, creating a clear need for precise and repeatable gas measurement. Without direct measurement, manufacturers cannot verify compliance or ensure consistent product performance.

Related reading:

Chinese Insulating Glass Standard GB/T 11944: Gas Concentration Measurement

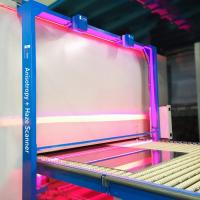

Introducing Non-Destructive Argon Gas Measurement in Production

To meet these requirements, Xinruineng introduced a convenient and lightweight, non-destructive argon gas measurement device from Sparklike in 2023. Since then, Sparklike Handheld has been used continuously as part of the company’s quality control process to measure double-glazed units.

Non-Destructive Testing Without Damaging the Glass

One of the key advantages of the Sparklike Handheld argon gas analyzer is its ability to perform non-destructive measurements. The insulating glass unit remains intact, and the argon concentration can be measured within two seconds. The device directly displays the gas concentration percentage, enabling immediate verification against standard requirements. Read more about Sparklike’s unique technology to measure insulating gas concentration non-invasively.

Improving Quality Control Efficiency on the Production Line

Ease of use is critical for daily production. The Handheld analyzer is well suited for high-frequency spot checks, improving inspection efficiency while maintaining measurement accuracy. This supports stable insulating glass quality and consistent thermal performance across production batches.

Measurement for Production and On-Site Applications

Xinruineng emphasize how Sparklike Handheld is lightweight and possible to measure anywhere. Powered by a lithium battery, it can be used flexibly on production lines and at construction sites when required. Maintenance is straightforward, and proper handling ensures long-term measurement accuracy.

Verifying Compliance and Optimizing Production Processes

By integrating argon gas measurement into its quality control workflow, Xinruineng can verify that insulating glass units meet the Chinese national standard requirements. This approach supports regulatory compliance, improves process control, and reduces the risk of undetected gas fill issues.

Read the original reference letter from Xinruineng

Read more Sparklike customer stories to see how manufacturers around the world are ensuring reliable gas-filled units with Sparklike technology.

600450

600450

Add new comment