Date: 28 October 2025

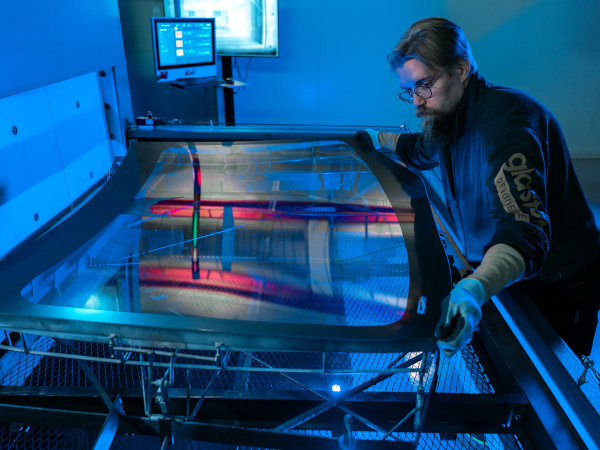

“Our operators didn’t have any experience with tempering machines, but with Autopilot, operating the Glaston furnace has been very easy,” says Marius Vaganyik, Production Manager at OviBest. “They only need to touch the screen, select the type of glass to temper – and the magic happens.”

From local workshop to international supplier

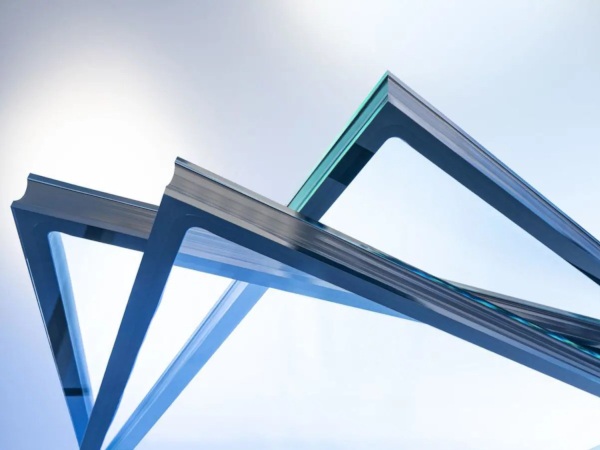

Founded in 2004 in Carei, Romania, close to the Hungarian border, OviBest has grown from a small workshop with just a few employees to a company of around 80 people. While the company began with PVC window production, today its main focus is on glass manufacturing, producing a wide range of insulating glass units, as well as tempered and laminated glass. OviBest also provides integrated solutions for residential, commercial and industrial projects, offering both complete window and door systems as well as glass products sold separately.

Thanks to its convenient location, OviBest serves customers both in Romania and Hungary, as well as across Italy, France, Austria and Germany. Today, about half of its production is exported.

“What makes us unique is our focus on quality, reliability and flexibility,” says Marius. “We manage the entire process from glass processing to final installation, ensuring our customers receive complete, ready-to-use solutions – no matter where they are located.”

From outsourcing to independence

After years of external tempering, OviBest made the decision to add in-house tempering capabilities to eliminate multiple bottlenecks affecting its competitive edge.

Marius explains: “Earlier, we cut the glass and delivered it to our partners for tempering. Often, when we went to pick the glass up, two or three pieces were missing because they had been damaged during transport or in the processing. So, we had to start from scratch again. This whole process drove our costs up and extended the overall execution time.”

“In addition, the demand for tempered glass has been growing over the last several years,” he adds. “Some projects we couldn’t win because our pricing was higher due to outsourcing. We were losing business to companies that already had their own furnace.”

The first tempering line – and the first Glaston

Before ordering, OviBest took a careful approach. “We studied the market, compared different suppliers and visited two or three other factories in Romania to see their furnaces,” he explains. “Everywhere we went, we heard the same thing: you can’t go wrong with Glaston. In addition, Glaston is a big name in processing equipment, and its strong international reputation was evident at exhibitions. All this gave us additional confidence.”

Although it was the company’s first-ever tempering furnace, the choice quickly proved right. Delivered and installed in June 2025, the new Glaston furnace has been running smoothly from day one.

“We made a significant investment in this new tempering line, and we are confident that it will help our company grow and strengthen our position in the market,” Marius says.

Autopilot – as easy as using a smartphone

To ensure a smooth start despite their lack of experience in glass tempering, OviBest equipped the line with Glaston Autopilot. The results have been exactly as expected – uniform quality and the ease of process control.

“We selected Autopilot to simplify operation and minimize adjustment time. Full automation ensures both efficiency and production stability,” he says. “And with Autopilot, it’s as easy as using a smartphone – you just touch it, and the magic happens.”

Marius goes on to explain that even someone on their first day can operate the machine. “Without Autopilot, that wouldn’t be possible. There are typically a lot of settings that may make it hard to get the tempering right. If you don’t know what you are doing, you could even damage the machine.”

Uniform results and reduced noise

Along with automated control systems, the furnace includes advanced convection, ensuring uniform heating and consistent glass quality. Plus, the noise reduction cabinet was also added to the line. “This is another great feature,” Marius says. “Everything is enclosed, and all the noise stays inside. We’ve seen other companies without this feature, and the furnace is so loud you can’t even talk near it.”

With its own tempering capacity, OviBest has eliminated breakage risks, reduced costs and made its entire process smoother, strengthening its competitiveness in the market.

Focused on growth and efficiency

Today, OviBest is preparing for the next stage of steady growth it has achieved over the past 20 years. “We want to grow in the future. In particular, we want to focus on expanding our exports and continue investing in modern, energy-efficient technologies,” he says.

With Glaston technology, the company is now well equipped to take the next step on its journey.

600450

600450

Add new comment