Date: 5 January 2026

Markets have been tough. But here’s an idea that is changing the way the glass machinery market works.

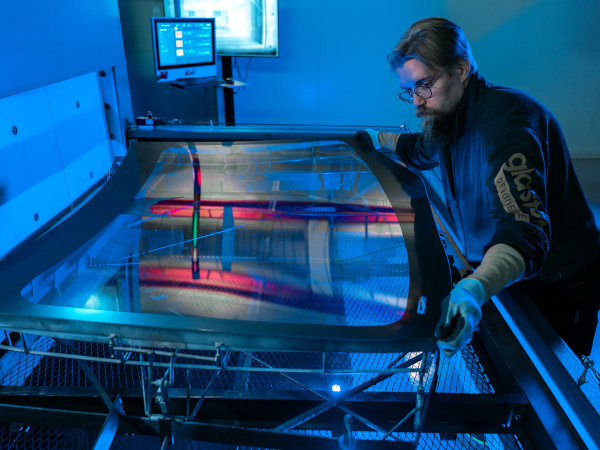

Every piece of machinery has a story – and deserves a second life.

Do you have a machine sitting idle in your factory that could fund your next big upgrade? Has business changed, so your machines aren’t producing enough of the type of glass needed to meet demand? Would you like to free up floor space – or gain cash to make up for a gap in earnings? Would you need to trade up to more sophisticated technology?

Although a machine may no longer fit your production needs, it still carries real monetary value that can be released through Uniglass ReLife. And even non-operational equipment can be valuable as donors for spare parts or refurbishment projects in global markets.

Changing the second-hand glass machinery market

Uniglass and GlassBaltic have joined forces to change the way that the second-hand glass machinery market works.

We are proudly launching Uniglass ReLife.

ReLife provides a systematic approach to help you sell – and get the best value for your machine.

The process begins with a simple online request – and we take it from there. All you need to do is upload your existing machine details in our Uniglass configurator to request an estimate. Our team will then review the information and follow up with the valuation. Reselling unused equipment not only frees up financial value – but also productive floor space that can be used for new technology or additional capacity.

Then GlassBaltic takes over to refurbish, maintain and find the best home for your machine where there is new demand – often in different regions or markets. They bring it back to life for someone else – sometimes even halfway across the world. What’s old for your business can be a lifeline for someone else.

What makes our approach different?

Our systematic, all-in-one approach makes selling easy. You don’t need to deal with multiple parties. Once you submit your request – we take it from there. Uniglass and GlassBaltic handle the entire process end-to-end – from valuation to refurbishment, relocation and installation.

Part of Glaston, with its decades of top-notch glass processing technology and solutions, Uniglass uses its digital capabilities to estimate a starting price for your machine. The final price depends on how fast you need to find a new home for your equipment that may be too slow or too energy consuming for the years ahead.

GlassBaltic, in turn, has global reach and proven experience, working in the business since 2017. The company of 15 strong, has sold machinery to 65 countries on every continent. Sometimes even shipping machines by airplane to get them to their destination, if needed.

Together, we provide fully furbished equipment with a warranty, offering true peace of mind.

Each project is unique, and we aim to add the greatest value for our customers, achieving a win-win-win outcome for sellers, buyers and partners throughout the entire chain.

Closing the loop

This isn’t only about transferring machinery from one user to another. It’s also innovation in motion – a model that is more than a one-off transaction.

It’s about giving your equipment a second life, helping others achieve their business dreams and contributing to a more circular, sustainable glass processing industry.

Ultimately, Uniglass ReLife translates into three clear benefits: unlocking capital from aging machinery, freeing production capacity and extending equipment life in a sustainable way.

Our story is just beginning

Stay tuned for step-by-step guides, success stories and real-life examples of how the Uniglass-GlassBaltic collaboration is reshaping the world in glass processing machinery.

Ready to see your machine come back to life?

ReLife is waiting at https://uniglass.com/relife/!

600450

600450

Add new comment