Photo source

Glaston Corporation

Date: 5 January 2026

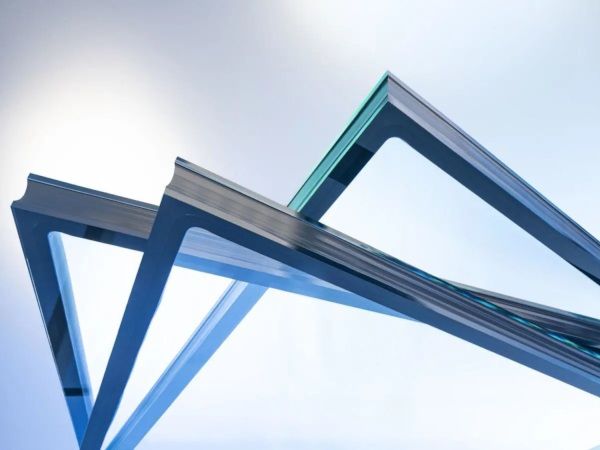

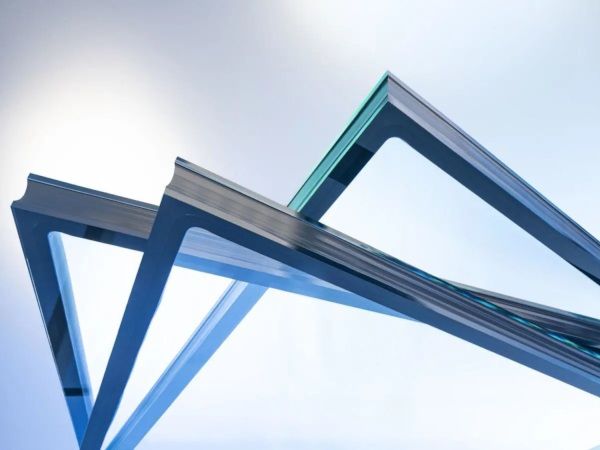

Discover how the new Glaston TPS® PRO technology sets a new benchmark in insulating glass manufacturing.

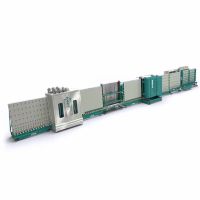

Unlike conventional systems, the TPS® PRO directly applies Thermo Plastic Spacer (TPS®) onto the glass plate—enabling fast, flexible production of IG units, multilayer and solar panels with up to 15% higher yield thanks to its new control system and optimized process sequence.

Key Benefits at a Glance

- Efficiency: Faster throughput, higher first-pass yield

- Quality: Consistent spacer geometry & edge sealing

- Scalability: Rapid product changeovers with minimal downtime

- Sustainability: Reduced waste and energy for a greener footprint

- ROI: Optimized processes translate to significant cost savings

600450

600450

Glaston Corporation

2026-01-05T05:00:00

Glaston Thermo Plastic Spacer TPS®PRO: Next‑Gen IG Manufacturing

glassonweb.com

Add new comment