Date: 8 May 2025

At China Glass 2025, Glaston once again leads the way with pioneering solutions in glass processing. As the original innovator in the glass processing industry, Glaston continues to set the standard with advanced technology, exceptional reliability – and comprehensive lifecycle support. Explore our latest breakthroughs designed for unmatched efficiency and precision.

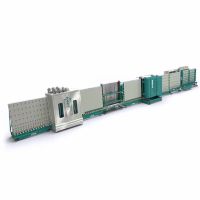

Insulating glass manufacturing

Glaston TPS® – the most flexible IG manufacturing

Since the launch of Glaston COMFORT TPS® technology last year, the COMFORT TPS® lines, available exclusively in China, have achieved great success. TPS® simplifies the production of insulating glass units by using only one machine instead of several components. This reduction in complexity leads to faster cycle times and significant energy savings.

TPS® is a modern, flexible and efficient solution for producing insulating glass units and multilayer solar panels. By applying Thermo Plastic Spacer material directly onto the glass plate, TPS® eliminates the need to stock different spacer profiles and connectors. Changes to spacer width can be made during the process without losing time. TPS® has already been installed at over 200 glass processing facilities worldwide.

Glaston COMFORT’SEALER – an automatic sealing robot

Glaston’s automatic sealing robot, COMFORT’SEALER, transforms the COMFORT BOX into a fully automated insulating glass production line. With gear pump dosing technology, COMFORT’SEALER offers high material dosing accuracy, precisely determining the sealing depth and width and applying the exact volume of sealing material required.

Glass tempering

Glaston tempering technology facilitates the efficient use of the entire furnace bed during the tempering process. This is crucial for maximizing production capacity and ensuring consistent quality of tempered glass. Glaston intelligent process automation ensures precise heating and cooling cycles. The Glaston Roller Heat Control (RHC) technology minimizes quality issues caused by roller heat disturbances. Maintaining uniform roller temperatures helps in achieving full bed utilization and reduces defects like glass warping.

Glaston TC Series – energy-efficient production

The TC Series tempering furnace utilizes the Chinook circulated air convection system, which reduces energy consumption to an absolute minimum. This ensures faster heat transfer for shorter cycle times, resulting in reduced overall production costs. With automatic process adjustment based on numerous measurements, Chinook minimizes operator input while maintaining high capacity.

Glaston RC Series – easy processing for any glass type and thickness

The Glaston RC Series offers effortless tempering for all glass types, from shower doors to architectural glass. It is easy to operate, requiring minimal effort for smooth processing. The accurate and intelligent heating system maintains impeccable glass quality even at increased production rates. The RC Series boasts high uptime and can be upgraded to meet evolving future processing needs. It also facilitates easy maintenance and guarantees the best availability of spares and support.

Mobility glass processing

Glaston CHAMP EVO – an evolution in mobility glass pre-processing

Glaston CHAMP EVO represents the latest CHAMP mobility glass pre-processing line generation. The grinding machine boasts higher precision, energy-saving linear drives, and a freely movable glass holding system for shorter changeover times. The line features lighter and better-optimized moving parts, such as the cutting bridge and grinding table.

Glaston MATRIX EVO – the best technology for tomorrow’s automotive glass

The new Glaston MATRIX EVO automatic bending furnace revolutionizes the bending of automotive windshields and sunroofs. It offers the best optical quality for applications such as ADAS, HUD and coated glasses with complex shapes. MATRIX EVO is highly modular and available in various chamber sizes and capacity configurations. Active convection enables faster heating, more efficient heat transfer and higher energy efficiency.

Automation and Upgrades

Glaston’s automation solutions and lifecycle services help maintain machinery efficiency and extend equipment lifetime. These upgrades ensure that the machinery meets industry demands with the latest technology.

Glaston Tianjin Open House – experience innovation firsthand

We invite you to visit our facilities and see Glaston glass processing technology in action!

Date: Thursday, May 29, 2025, Venue: Glaston Tianjin (80 mins by shuttle bus)

Visit Highlights:

- COMFORT BOX IG line

- COMFORT TPS® IG line with COMFORT’SEALER Demo

- CHAMP EVO processing line

Meet Glaston at China Glass 2025, Hall E1, Stand #300

Visit the event page: Glaston @China Glass 2025

600450

600450

Add new comment