Date: 18 June 2025

Do you want Reliable laminated glass cutting?

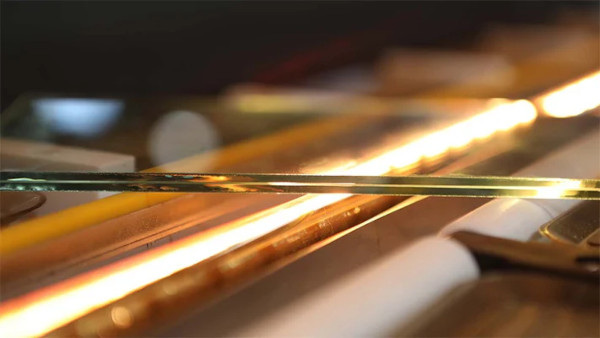

Better edge quality and edge strength

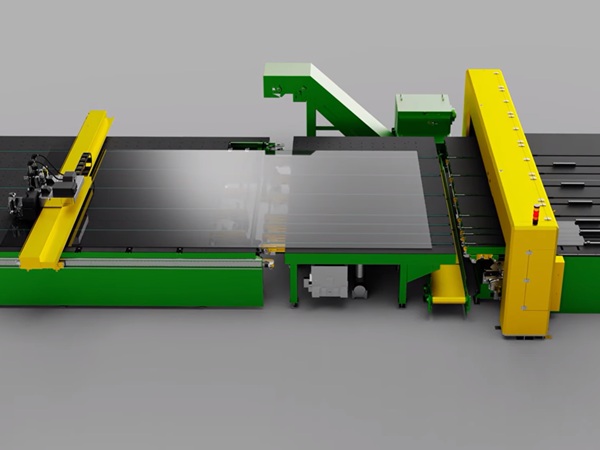

The special cutting head developed for the latest generation of VSL-A laminated glass cutting is also available for existing VB (VB-33, VB-45, VB-60) systems.

The sophisticated design of the cutting head reduces maintenance work by preventing cutting fluid from entering the guides. Low-friction guides ensure that the cutting pressure remains very constant, resulting in high-quality cut edges and preventing glass splinters.

Higher break quality

The use of the “anti-stress” suction bar reduces stress on the laminated glass, minimizing breakage. This ensures that breakage quality remains at the highest level even with varying material quality.

Do you want More output and better utilization?

More output due to shorter heating times

With the SIR heating retrofit kit, you can significantly reduce the heating times for foil separation. The 900 mm segmented infrared technology heats the foil optimally. This not only reduces energy consumption but also increases the efficiency of your production through higher output, as heating a 44.2 glass no longer takes 25 seconds but less than 10 seconds.

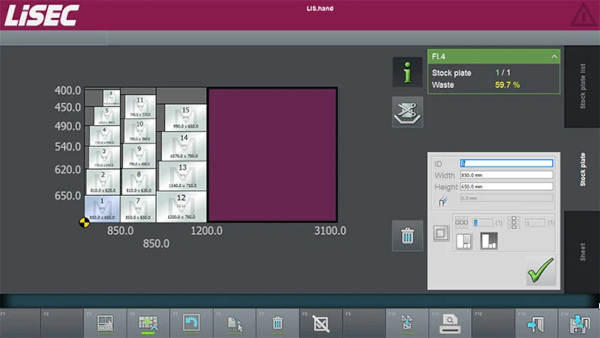

Remnant Plate removal without Production Interruption

The “Cut remnant plate first” software upgrade allows the remnant plate to be prioritized during cutting and separated from the storage plate. This keeps the glass loading and cutting process continuous without the remnant blocking the glass storage area. Removing the remnant does not affect the cycle time.

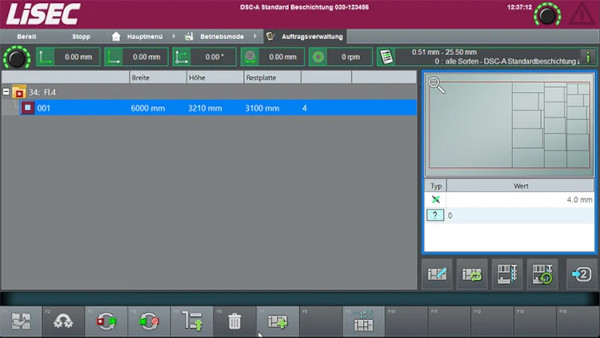

SHORTEr CYCLE TIMES EVEN WITH MANY Z-CUTS

This software upgrade significantly increases efficiency when there is a high proportion of Z cuts. By performing the Z cuts together with the X cuts, the operator can start manually breaking the Z cuts immediately after the Y cuts have been automatically broken, while the machine is already preparing the next subplate.

The smooth interaction between man and machine ensures a continuous production process that maximizes utilization and minimizes throughput times.

Summary

LiSEC's innovative retrofits offer significant advantages for optimizing existing machines. Improved edge and breakage quality, increased output rates, and more efficient cooperation between humans and machines not only make production future-proof, but also significantly more efficient.

LiSEC's experts will be happy to design a customized solution together with you.

600450

600450

Add new comment