Photo source

LiSEC Austria GmbH

Date: 7 May 2025

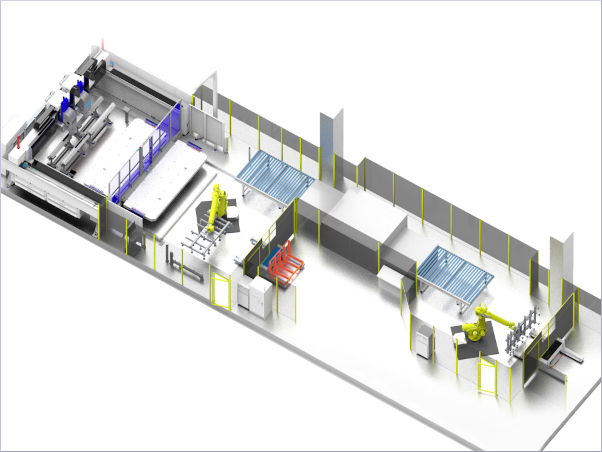

Automatic cutting and breaking of Low-E and solar control glass

In this video, the company showcases its fully automatic float glass cutting and breaking system for X-Y-Z cuts, featuring precise monitoring and control of the grinding wheel temperature during the Low-E edge deletion process.

- Real-time monitoring: An optical sensor continuously tracks the grinding wheel temperature.

- Automated correction: When the set temperature limit is reached, the system automatically activates cooling measures.

- Optimal performance: The grinding wheel temperature is consistently kept within the ideal range, preventing overheating and glazing.

With LiTEC Temperature Control, LiSEC redefines efficiency and reliability in glass processing.

600450

600450

LiSEC Austria GmbH

2025-05-07T07:00:00

LiSEC | DSC-A line: LiTEC Temperature Control decoating - cutting and breaking XYZ

glassonweb.com

Add new comment