Date: 7 August 2025

Viridian Glass works at the cutting edge. The company, which can reflect back on a long history in glass processing, keeps a constant an eye on the latest trends and developments. "The change to Australian building regulations has resulted in higher thermal efficiency requirements for new residential buildings. Over time, this will lead to significantly higher market penetration for double glazed units," says Dean Haritos, CEO of Viridian Glass, "Viridian has invested in in-house capability and capacity over many years to meet this demand. As the market continues to evolve, we will ensure that our facilities are optimised to efficiently meet the needs of our customers."

Implementing new trends in everyday production

In order to meet these new developments as part of the digital transformation, it is also important to scrutinise existing production equipment. "We are currently examining a comprehensive modernisation of one of our most important facilities and LiSEC is working with us to plan this measure. We are using LiSEC's expertise to guarantee that we optimise the product flow and achieve the right balance between automation and production flexibility. LiSEC is also helping us decide how best to initiate and implement this upgrade to minimise disruption to our business," explains Dean Haritos, who already relies on LiSEC for existing equipment and automation.

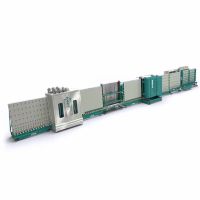

The centrepieces of the Viridian Glass production facility are the automated LiSEC cutting systems. "Our automated lines start with a LiSEC PKL, which is connected to several cutting tables that allow X, Y and Z breakouts, and which subsequently feed the LiSEC KSR. These systems enable us to deliver a consistently high quantity of quality glass to the tempering oven, resulting in an increased output of finished products."

Viridian was one of the first LiSEC customers in the world to connect a tempering oven fully automatically, eliminating the need for operators. The tempering bed is generated and loaded automatically. Production is therefore practically fully automated from the raw glass to the finished insulating glass unit.

Downstream of the LiSEC PKL with remnant plate storage is a LiSEC ESL-RS with automatic X-breakout, which supplies the LiSEC KSR and KSV glass edge grinding and edging systems fully automatically, and a LiSEC GFB-VB cutting table for laminated glass.

With the LiSEC PKL/SBL, Viridian Glass has the option of unloading the raw glass sheets directly from the inner loader frame, which is delivered by HGV and placed in glass storage, and transporting the sheets to the stationary LiSEC ATL glass loading station. The laminated glass is fed into the float line and travels past the oven via a bypass into the sorting system, which feeds the insulating glass line.

Highly automated production at Viridian Glass

Highly automated work is not only an advantage in view of the ongoing shortage of skilled labour; consistently high quality is also important to Viridian Glass in enabling the company to realise its strategy and vision. For Viridian Glass, trustworthy cooperation with its customers is central to its business activities. It forms the basis for the company's undertaking to it customers: Obsessive customer focus, the furthest-reaching presence and the most extensive production capacities, as well as industry-leading expertise and technological support for all challenges.

This requires a strong partner for the machines and solutions used in production. "A true test of cooperation is when things are not going well. During these times, LiSEC has taken responsibility and worked hard to get the right result for our company," says Dean Haritos on working with the LiSEC team. "LiSEC has the advantage of offering fully integrated machine and software solutions. This means we have one point of contact for any problems that arise. Furthermore, the business relationship with LiSEC has grown over the years – right up to management level. Gottfried Brunbauer and Oliver Pichler are an important element of the cooperation between LiSEC and Viridian. We feel listened to and supported when issues come up. That's what defines a good partnership."

As the largest glass processor in Australia, it is important for Viridian Glass to stay at the forefront of innovation. This is possible with the right employees and the right partners – like LiSEC – who can make a significant contribution, particularly in terms of quality and efficiency, and also when it comes to collaboration and exchange.

600450

600450

Add new comment