Date: 9 January 2026

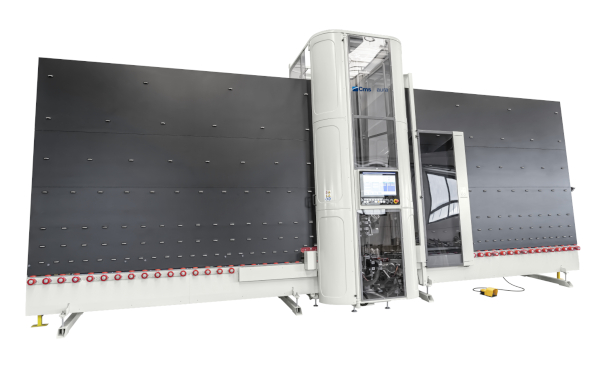

Designed for the automatic seaming of rectangular glass edges, aura works without water, reducing production and maintenance costs while simplifying overall system management.

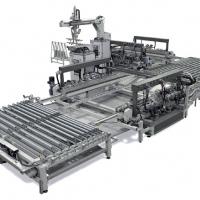

It can be installed as a stand-alone machine, in line with a vertical washer, or integrated into an insulated glass line: maximum flexibility for every production need.

Zero worries. Maximum productivity.

With CMS aura, the operator only needs to load the glass and start the cycle: the machine automatically measures height, length, and thickness, adapting its operating units to the glass dimensions.

The processing heads follow the glass profile, even in its irregularities, ensuring a constant and homogeneous glass removal along its entire length.

Monolithic, laminated, or low-e coated: the result is always precise, clean, and consistent over time.

Watch the video of CMS aura here!

Why choose aura?

- Cost savings: thanks to the absence of water in the process

- Productivity: operating speed up to 25 m/min, ideal for 3-shift production

- Total automation: automatic management of different thicknesses

- Safety and cleanliness: complete extraction of processing dust

The dry technology of CMS aura is the ideal solution for those looking for a reliable, compact, and ready-to-use system capable of optimizing processing time, costs, and quality.

600450

600450

Great News! Love it! Lanai Screen Repair