V. alla Porada, 188

Seregno 20831 MB

Italy

Officina Meccanica Schiatti Angelo S.r.l.

Find us on:

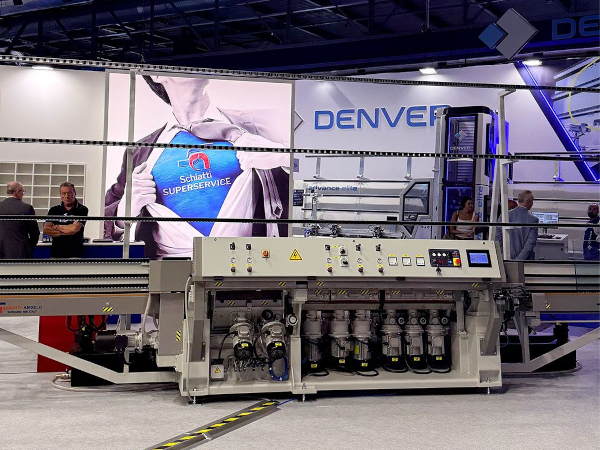

With more than 65 years of activity, a good knowledge of production problems, there are have been more than 17.000 machines manufactured.

These range from straight and double edgers, straight bevellers, automatic arrising machines, drillers and glass loaders/unloaders. This makes us an ideal partner for both small and big companies nationally and internationally.

At Schiatti, every step of the machine production process is run in-house: from the initial fabrication, machining, painting, and assembly up to testing and shipping taking the utmost care in every detail.

Schiatti, cover everything from the initial concept, it’s design, development final production; marketing and after sales service.

Service is not limited to only obtaining orders but includes continued assistance through a network of agents and representatives working in all strategic geographical areas.

Schiatti Angelo srl offers a wide range of machines for glass processing, a result of considering the problems presented by glass processors, from the small shop to the big companies.

- Straight edgers to grind and polish pencil, flat with arrisses, Ogee and waterfall edges for glass sheets from 3 to 55mm thick with electronically controlled automation device

- Double edging machines for simultaneous grinding and polishing on both glass edges. They can process the pencil or flat with arrisses edges, with electronically controlled automation devices such setting up and monitoring the working cycle; for glass size from 80 to 4.000mm in lenght and thicknesses from 2 to 20mm

- Complete grinding lines composed of two machines connected by a transfer table are available for processing all four glass sides

- Automatic and semi-automatic drilling machines with opposite heads

- Multi head drillers for the simultaneous execution of 2-3-4 holes

- Straight bevelers for the grinding and polishing of glass as to obtain a bevel from 3° to 45° on thicknesses from 3 to 25mm

- Loaders/unloaders

- Vertical drilling/milling machines

- Drilling centers

- Automatic arrissing machines

VIDEOS

Products

Technical Datasheet:

- Conveyor-track composed of rubber pads with six bearing, fixed to a chain that glide along steel guides

- The conveyor doesn't require continuous lubrication

- Manual adjustment of the diamond wheels and working speed

- Automatic adjustment of polishing wheels

- An electronic card displays and adjusts the track opening and closing according to the thickness to be worked (AR / 2MS - RI / 4MS)

- The spindles can accommodate two wheels to process a series of thicknesses

- Close–circuit water cooling system

- Protection and safety devices to protect the operator

- Electrical system in compliance to the EC in force

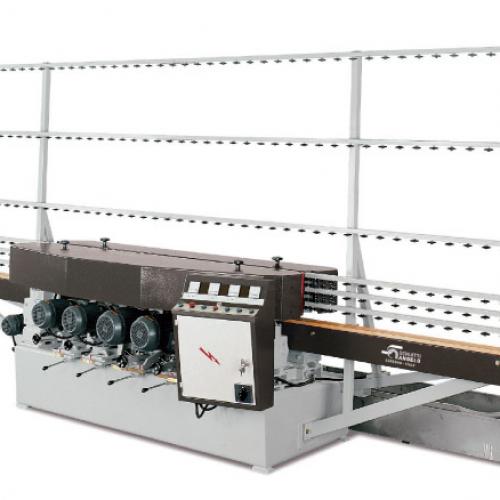

Technical Datasheet:

- Conveyor–track composed of rubber pads with six bearings, fixed to a chain that glide along steel guides

- The conveyor doesn’t require continuous lubrication

- Automatic adjustment on the thickness to be worked

- Independent adjustment of the diamond wheels

- Automatic adjustment of the polishing wheels

- Double speed motors for polishing wheels

- Possibility to work both with liquid and synthetic cerium oxide

- At the inlet of the machine a device allows the operator to increase or decrease the glass removal up to 4mm without the need to adjust the diamond wheels (except mod. FPS10 e FPS15S7)

- Input and display of the working parameters on PLC

- Close–circuit water cooling system

- Protection and safety devices to protect the operator

- Electrical system in compliance to the EC in force

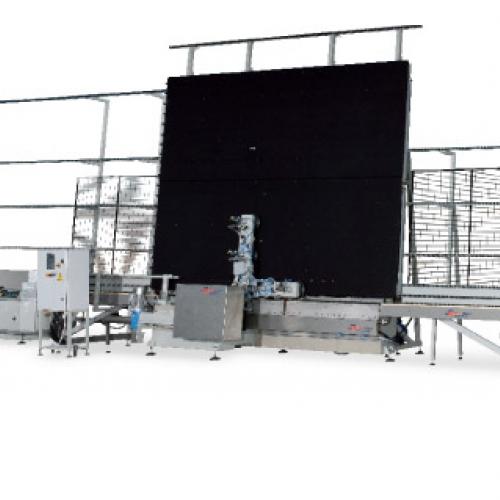

Technical Datasheet:

- Can be connected to straight-line edgers or bevellers

- Rotating arm fully automatic

- A system of photoelectric cells “reads” the glass sizes

- The PLC process the collected data and starts the working cycle

- Vacuum-pads hold the glass while rotating

- An automatic fan located on the backboard provides an air-cushion to prevent the glass-sheets being scratched during rotation

- A dog clutch manages the time of the working cycle

- Glass-sheets of any dimension can be processed in succession

- A set of photoelectric cells located along the line eliminate the risk of any glass impact

- Protection and safety devices to protect the operator

- Electrical system in compliance to the EC in force

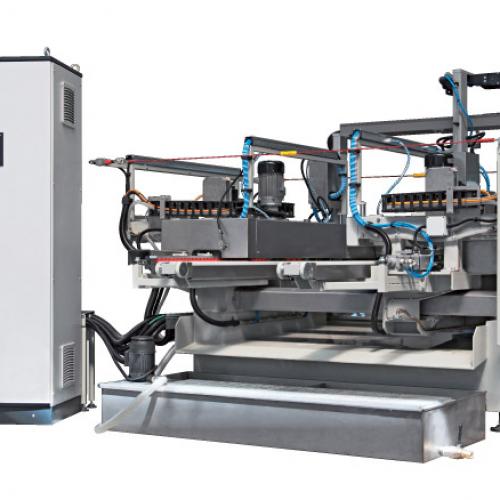

Technical Datasheet:

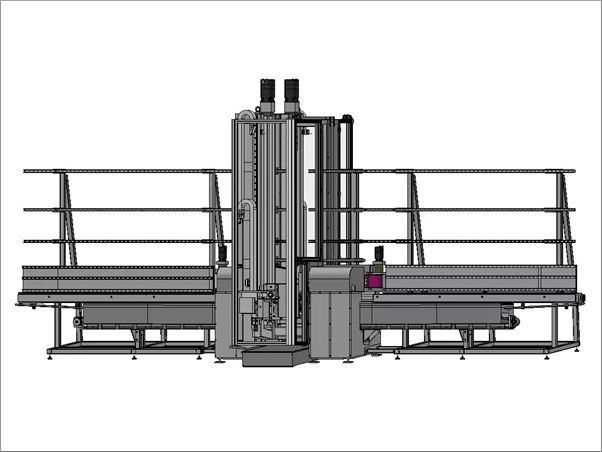

- The machine consists of 3 independent sections to optimize production

- Input and output conveyor equipped with toothed belts to transport the glass

- Two spindles with peripheral wheels carry out the processing of the glass sheets. Each spindle is completely independent of the other

- Processing of two sheets simultaneously

- A series of sheets of any size and thickness can be processed in succession

- The machine is completely automatic

- All the functions, commands and parameters are managed by a PLC which can be accessed from a touch screen panel

- Display of various processing statistics

- Close–circuit water cooling system

- Protection and safety devices to protect the operator

- Electrical system in compliance to the EC in force

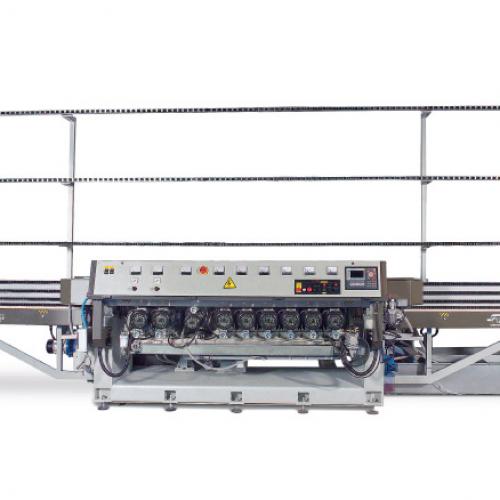

Technical Datasheet:

- The conveyor with polyurethane timing belts is dual-drive and can be adjusted to all thicknesses

- Squaring assembly to square up the glass sheets before grinding

- Aligning system to divide the amount of glass removed evenly on either side

- Independent adjustment of the diamond wheels

- Automatic adjustment of the polishing wheels

- The diamond and polishing unit can rotate externally to allow the operator to carry out maintenance work and tool changing

- PLC to adjust thickness, working speed, devices, to input and display all the working parameters and diagnosis of faults

- Close –circuit water cooling system

- Protection and safety devices to protect the operator

- Electrical system in compliance to the EC in force

- Complete grinding lines made up of two grinding machines and a transfer table can be supplied

Technical Datasheet:

- The conveyor with polyurethane timing belts is dual-drive and can be adjusted to all thicknesses

- Squaring assembly to square up the glass sheets before grinding

- Aligning system to divide the amount of glass removed evenly on either side

- Independent adjustment of diamond wheels

- Automatic adjustment of polishing wheels

- The diamond and polishing unit can rotate externally to allow the operator to carry out maintenance work and tool changing

- PLC to adjust thickness, working speed, devices, to input and display all the working parameters and diagnosis of faults

- Close–circuit water cooling system

- Protection and safety devices to protect the operator

- Electrical system in compliance to the EC in force

- Complete grinding lines made up of two grinding machines and a transfer table can be supplied

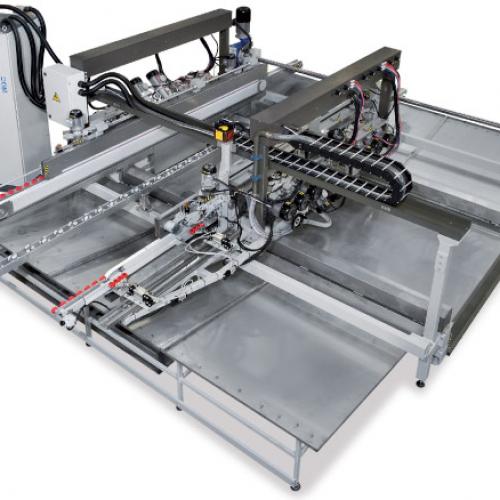

Technical Datasheet:

- The conveyor with polyurethane timing belts is dual-drive and can be adjusted to all thicknesses

- Two pairs of squaring stops to square up the glass sheets before the grinding process

- Each unit has been designed to accommodate up to 3 diamond tools on the same spindle

- Two corners can be processed simultaneously and each can be of different radius or profile

- The centering of the wheels is automatic

- The spindles can be positioned to allow the operator to perform, in a simple and fast way, maintenance and replacement of wheels

- All functions, commands and parameters are controlled by the touch-screen CNC

- Close–circuit water cooling system

- Protection and safety devices to protect the operator

- Electrical system in compliance to the EC in force

- The machine can be put in line with double edgers models. BFT and BFP

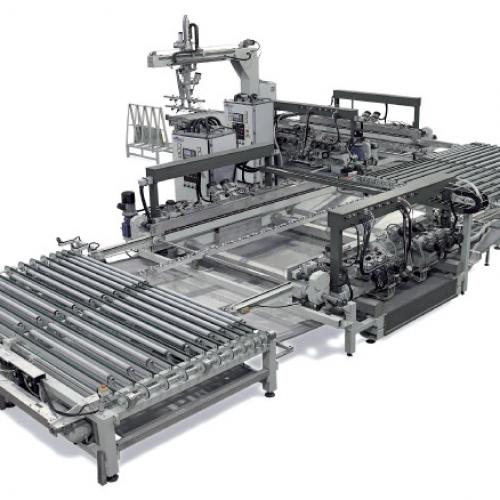

Technical Datasheet:

- Synchronization of loading speed with that of the working speed of the edger

- Sensors detect glass presence

- Suction cups can be positioned according to the size of the glass sheet

- A vacuum system creates the vacuum necessary to pick-up glasses

- Sheet holder carriage, rolling table and protection barrier are included in the supply

- Automatic working controlled by PLC

- Protection and safety devices to protect the operator

- Electrical system in compliance to the EC in force

- The machine can be put in line with double edgers

Technical Datasheet:

- Conveyor–track composed of rubber pads with six bearings, fixed to a chain that glide along steel guides

- Automatic lubrication system

- PLC touch screen to adjust thickness, working speed, mitering system and to input and display all the working parameters and diagnosis of faults

- Independent adjustment of diamond wheels

- Automatic adjustment of polishing wheels

- Double speed motors for polishing wheels

- A series of ammeters display loads on motors

- Close–circuit water cooling system

- Protection and safety devices to protect the operator

- Electrical system in compliance to the EC in force