Date: 13 October 2025

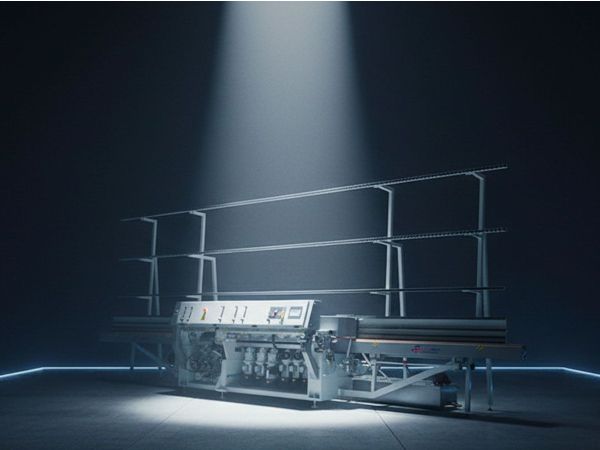

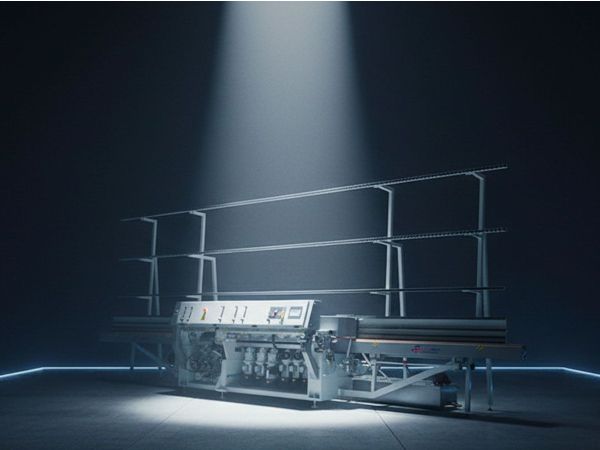

80% less friction thanks to rubberized pads

SME10 redefines straight line edger standards thanks to its revolutionary conveyor system. Rubberized pads with ball bearings that roll along a tempered steel guide, are mounted on chains and ensure processing with variable angles from 0° to 45° while maintaining consistent millimetric precision. This configuration reduces friction by up to 80% compared to traditional systems and eliminates vibrations, ensuring flawless finishes both on flat edge and arrises, with superior-quality cerium oxide polishing.

Smart Automation and Complete Control

The technological heart of the SME10 is its integrated touch-screen PLC, which enables operators to precisely adjust glass thickness, processing speed, and tilting angle while displaying all operational parameters in real time.

50% Less Maintenance

The predictive diagnostic system continuously monitors pressures and vibrations, reporting anomalies before they become failures—reducing routine maintenance interventions by 50%.

Independently adjustable diamond wheels, allow a precise calibration of the required power for each type of processing, while automatic polishing wheels with self-regulation system minimize manual interventions.

Energetic Efficiency and Sustainability

The SME10 stands out for its reduced consumption: just 17.7 kW for the entire processing cycle. The closed-circuit water cooling system completely eliminates water waste, optimizing the thermic efficiency of the production process and reducing environmental impact.

Customization and Versatility

The SME10's modular design enables customized configurations through numerous optional features: from clutch systems to automatic thickness control, from front adjustment of the back arris to other technical solutions that adapt the machine to every specific production requirement.

This combination of innovation, efficiency, and reliability makes the SME10 the ideal choice for companies seeking to optimize production while reducing operational costs and environmental impact, without compromising finished product quality.

600450

600450

Add new comment