Via Abbondanza 11/13

Carbonate 22070 CO

Italy

Adelio Lattuada S.r.l.

Find us on:

The company, founded at Carbonate (Como) in 1978, first attended, above all, to technical assistance services. At the beginning of the eighties, it started to manufacture automatic corners grinding machines and later straight-line edging machines (in 1983) and bevelling machines (since 1989).

In 2017 LATTUADA NORTH AMERICA, INC. has been established in Northwood (OH), in order to strengthen the presence in US and provide any type of pre- and post-sale services.

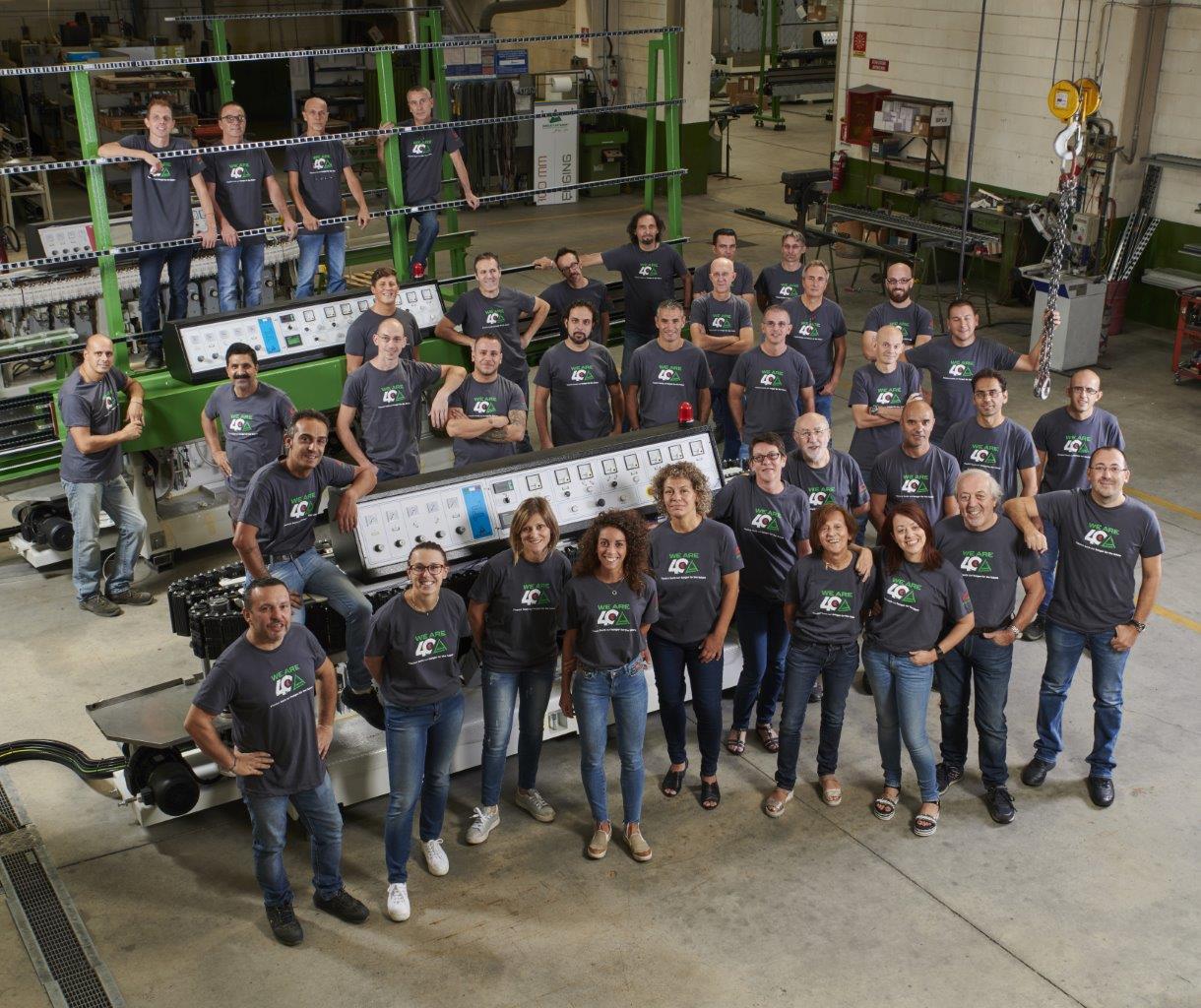

From the establishment up to now the development has been uninterruptedly if you think that in 1979 Adelio Lattuada worked alone while his staff is now composed of 40 persons planning, mounting and testing the machines.

Our current machines range includes:

- more than 30 models of electronic or with PC straight-line edging machines for the flat edge with arris and with variable angle from 5 to 16 wheels

- peripheral edging machines from 4 to 8 wheels

- vertical edge polishers from 9 to 13 wheels

- complete line of double-edgers from 8 to 11 wheels on each side, for the flat edge with arris

- more than 10 models of electronic or with PC straight-line bevelling machines from 7 to 14 wheels

- 4 models of automatic corners grinding machines

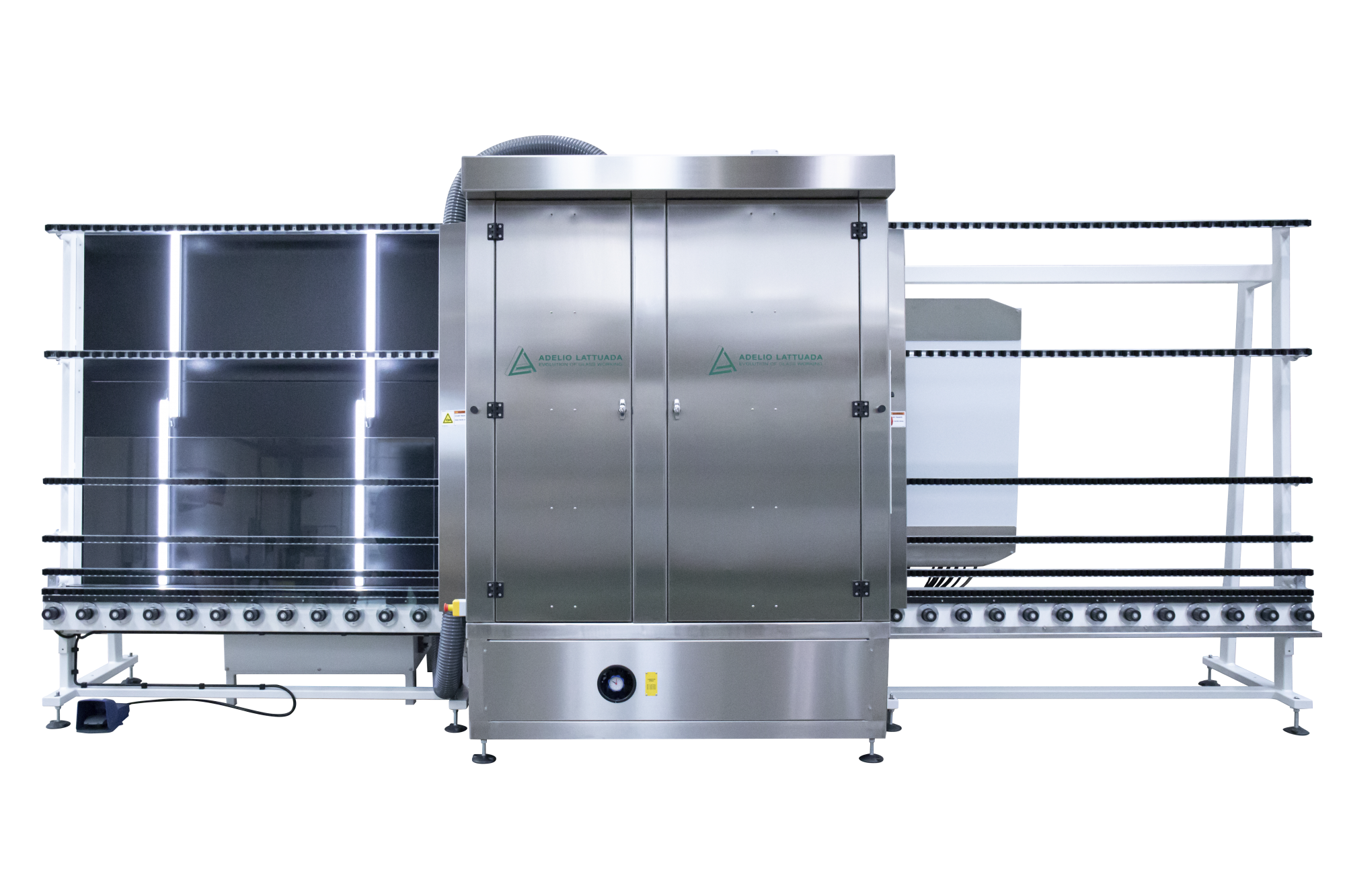

- complete range of vertical washing machines

- complete line of horizontal drilling machines

Facts and figures

- From the foundation until today more than 2.000 machines sold all over the world

- 40 employees taking care of the machines' designing, assembling and testing

- Products mostly (85-90%) exported both in EEC and EXTRA-EEC countries

- Products sold in more than 90 different countries

- 3.000 m2 production area

- More than 90% of satisfied customers purchasing a second machine

LAST VIDEOS:

Vidraria Armando

Company Video Rebranding 2022 + Customer Satisfaction 2022

Lattuada & Knittel Glass Robotic line @ Glasstec 2022

petrA - evolution of stone processing

A-WR System 3.0

Lattuada + Knittel full automatic robotic line

Products

Edging machines

Our range of straight-line edging machines counts a huge number of models, divided into some major lines: AL, TL, TLR and TLS series.

The AL range includes small-middle sized straight-line edging machines from 4 up to 10 wheels for the processing of the flat edge with arris, pencil edge, OG or with variable angle.

The TL range includes models of middle-big sized straight-line edging machines for the flat edge with arris, pencil edge, OG or with variable angle from 9 up to 11 wheels.

The TLR range, which is the most used by the major producers of stratified glass for the heavy building industry in the Northern Europe, is addressed to all glaziers with huge production of glasses with a great thickness.

The TLR series for the processing of flat edge with arris includes models from 8 to 14 wheels, while the variable angle models are available from 9 to 16 wheels.

At last the TLS range, which represents an evolution of our TLR edging series, includes models with 13 and 16 wheels for the variable angle, able to carry glass sheets with a weight up to 1.500 Kg and with a thickness up to 100 mm.

All Adelio Lattuada models offer an optimal duration/cost ratio. This is a very important characteristic that is always fundamental for glassworks because of their need of machines with a long working life. In fact, there are Lattuada machines still working after 20 years and with up to two million meters processed, while the average working life is normally about five to six years if quality and production levels have to be maintained.

Edging machines with variable angle

Peripheral edging machines

petrA by Adelio Lattuada: a line of vertical edge polishers dedicated to the processing of stone, ceramic and composite materials.

Thanks to decades of experience in the processing of this type of materials, with petrA series machines it is possible to perform high precision and quality processing in an extremely simple way: flat edge, miter up to 45° or 60°, grooves for drips or other uses and alternate arrises for a perfect coupling of two angled slabs. All these processes can also be performed on very small strips or pieces.

Available in standard versions from 9 up to 13 spindles, with many options and accessories available (including innovative automation solutions and robotic integrations) and with the possibility to include customized features according to customer needs.

petrA machines are strong, reliable and easy to use, designed to work continuously for many hours a day in continuous cycle.

Maintenance is extremely simple and economical, with immediate and customized assistance.

These are some of the reasons why Adelio Lattuada can count on different references of leading companies in stone, marble, ceramic and innovative materials processing in different countries around the world.

petrA, evolution of stone processing

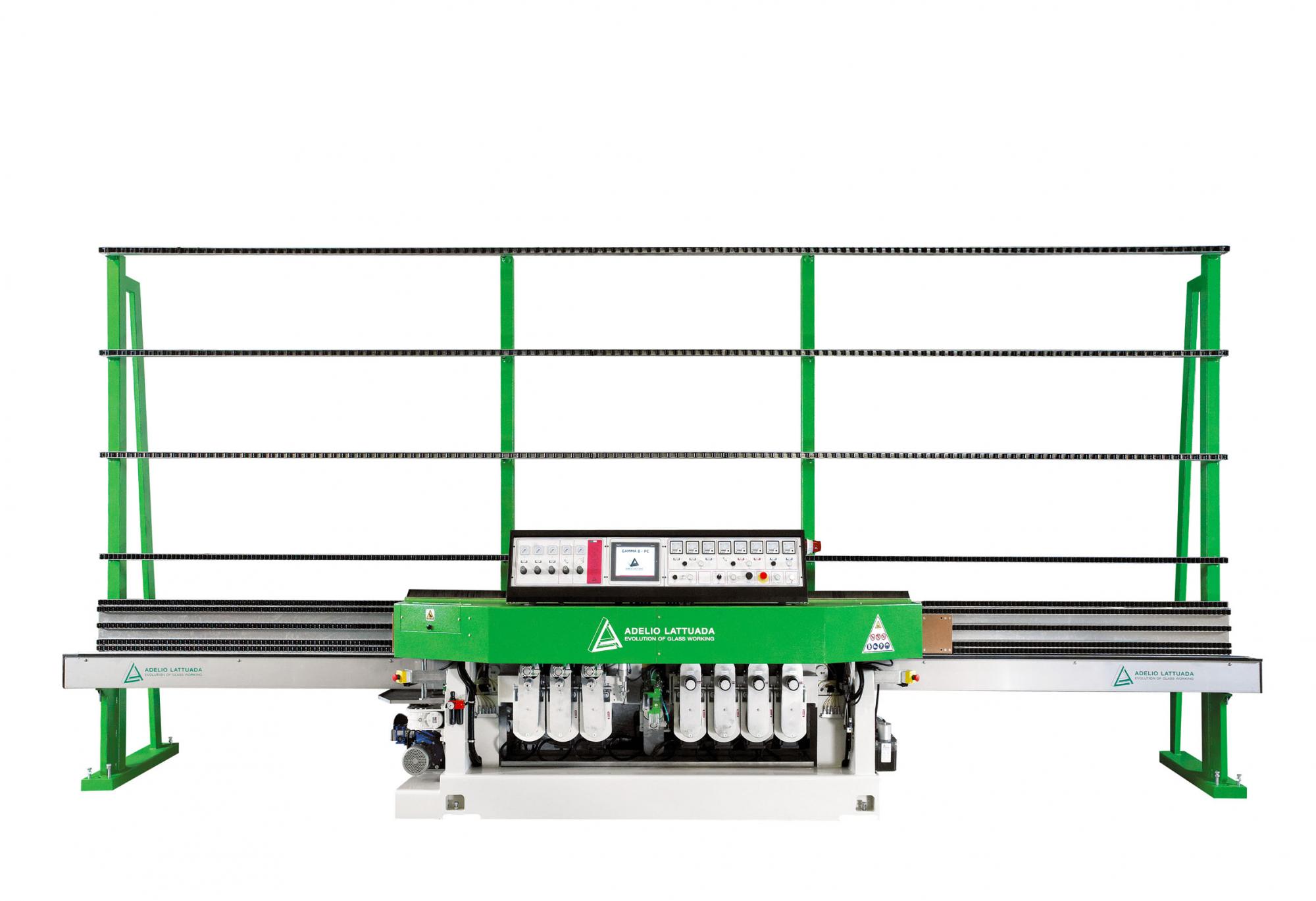

BETA 8

Double-edger for the processing of the flat edge with arris with 8 cup wheels and possibility to add one dubbing device or a cerium wheel on each side.

Equipped with an automatic system of glass squaring and centring, it also has a colour touch-screen panel, conceived in order to help the machine's check, use and maintenance. Thanks to this panel, the operator can manage the (automatic/manual) cycle of the processing’s preparation, execution and monitoring with a series of very useful functions such as for instance the recording of the most frequent processing, the real-time statistics of use, the maintenance and alarms management. At the entrance side of the machine there are two steerable panels on which we have placed the ammeters for the wheels’ power absorption as well as other controls which can be helpful during the glass insertion phase. The rugged and strong bedplate of the machine is realized in arc-welded steel, duly nerved in order to avoid torsion effects of the structure. The movement transmission system is realized through a broached and toughened transmission bar, placed in a superior position with regard to the belts for guaranteeing: a better precision and durability of the bar and both the synchronism and the easy substitution of the belts. The main strong points of our double edger are the modern technologies used, the high-quality components for the electronics, the sensoristics and the automation and therefore the simple and quick setting and positioning. For this reason it is particularly suitable also for small production lots.

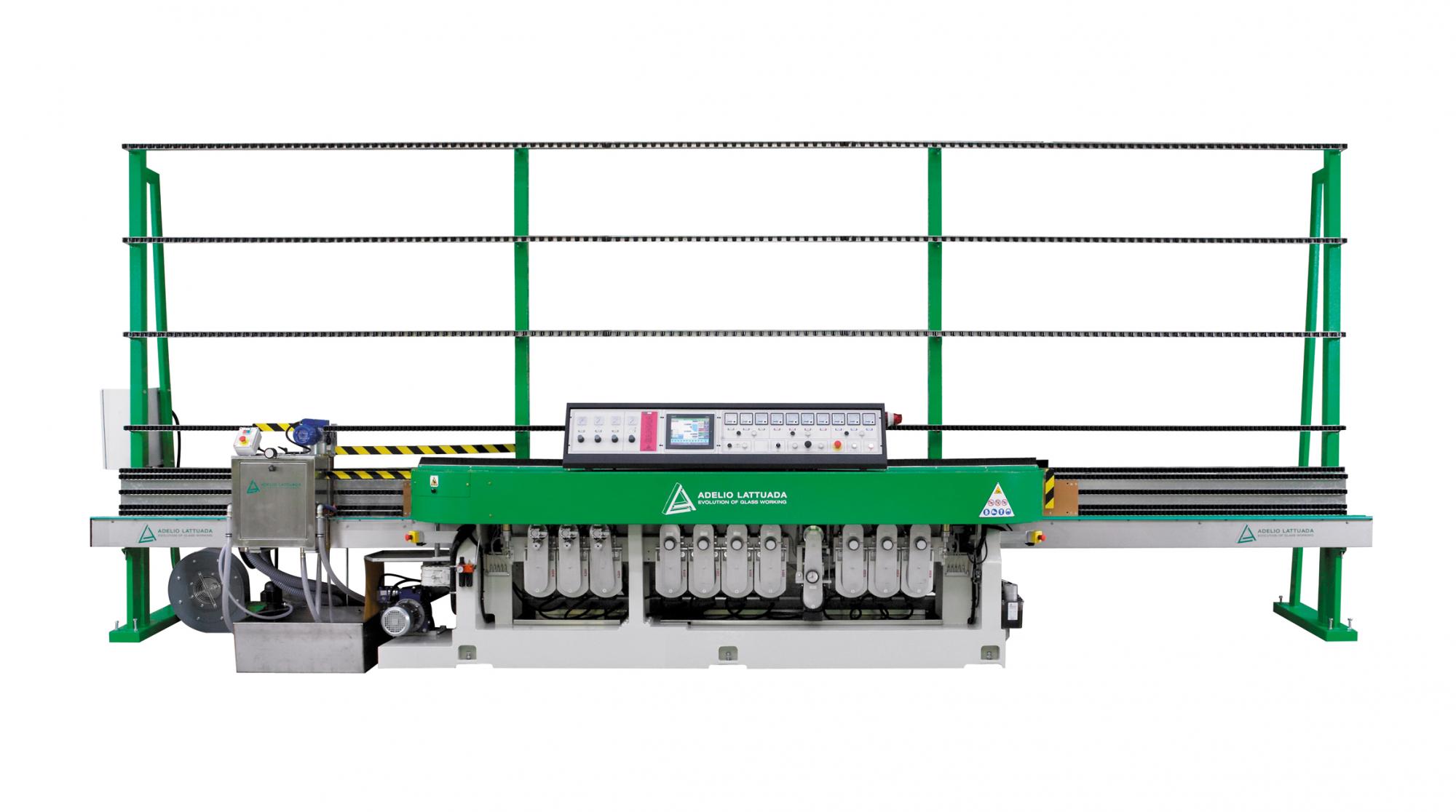

BETA 10

Double-edger for the processing of the flat edge with arris with 10 cup wheels and possibility to add one dubbing device or a cerium wheel on each side.

Equipped with an automatic system of glass squaring and centring, it also has a colour touch-screen panel, conceived in order to help the machine's check, use and maintenance. Thanks to this panel, the operator can manage the (automatic/manual) cycle of the processing’s preparation, execution and monitoring with a series of very useful functions such as for instance the recording of the most frequent processing, the real-time statistics of use, the maintenance and alarms management. At the entrance side of the machine there are two steerable panels on which we have placed the ammeters for the wheels’ power absorption as well as other controls which can be helpful during the glass insertion phase. The rugged and strong bedplate of the machine is realized in arc-welded steel, duly nerved in order to avoid torsion effects of the structure. The movement transmission system is realized through a broached and toughened transmission bar, placed in a superior position with regard to the belts for guaranteeing: a better precision and durability of the bar and both the synchronism and the easy substitution of the belts. The main strong points of our double edger are the modern technologies used, the high-quality components for the electronics, the sensoristics and the automation and therefore the simple and quick setting and positioning. For this reason it is particularly suitable also for small production lots.

BETA 11

Double-edger for the processing of the flat edge with arris with 11 cup wheels and possibility to add one dubbing device or a cerium wheel on each side.

Equipped with an automatic system of glass squaring and centring, it also has a colour touch-screen panel, conceived in order to help the machine's check, use and maintenance. Thanks to this panel, the operator can manage the (automatic/manual) cycle of the processing’s preparation, execution and monitoring with a series of very useful functions such as for instance the recording of the most frequent processing, the real-time statistics of use, the maintenance and alarms management. At the entrance side of the machine there are two steerable panels on which we have placed the ammeters for the wheels’ power absorption as well as other controls which can be helpful during the glass insertion phase. The rugged and strong bedplate of the machine is realized in arc-welded steel, duly nerved in order to avoid torsion effects of the structure. The movement transmission system is realized through a broached and toughened transmission bar, placed in a superior position with regard to the belts for guaranteeing: a better precision and durability of the bar and both the synchronism and the easy substitution of the belts. The main strong points of our double edger are the modern technologies used, the high-quality components for the electronics, the sensoristics and the automation and therefore the simple and quick setting and positioning. For this reason it is particularly suitable also for small production lots.

From the GAMMA 7 model, conceived for small/medium productions, we arrive to the GAMMA 8 and GAMMA 613 models, which have been designed for bigger productions instead.

To the glaziers who are in need of bevelling machines operating at a high speed and at the maximum quality level, are addressed all the “bigger sisters” instead.

In detail:

- GAMMA 614, 713, 714, 633 and 723 for the processing of bevel and pencil edge

- GAMMA 643, 723 and 743 for the processing of bevel and flat edge

All models are available both in the electronic version and with a PC.

They are addressed to those glaziers with mass production of brackets or doors for the furniture industry and they are able to process radium and straight corners up to 20 mm glass thickness in less than 30 seconds.

The differences among them concerns: the height, the brushes number and the maximum loading weight.