Date: 4 November 2025

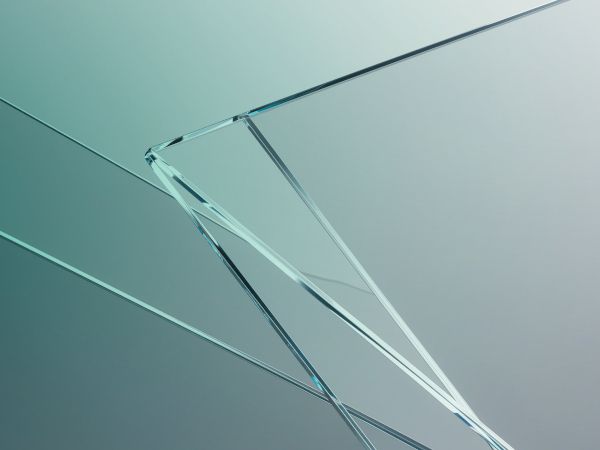

However, the progressive reduction in glass sheet thickness introduces a series of production and processing challenges, particularly in grinding. Achieving precise and uniform edges without compromising the safety and strength of the material becomes essential.

Why grinding thin glass is complex?

Reducing glass thickness increases the material's fragility, making it more susceptible to breakage during grinding. This means balancing precision and speed without affecting the quality of the final product. Even the smallest variation in thickness or applied force during processing — without proper care — can result in errors and significant waste, negatively impacting productivity.

Relying on high-performance machines is not enough: correct management of parameters during the grinding phase is fundamental. Choosing the right straight-line grinding machine model based on glass thickness and the desired result is essential. At the same time, maintaining the correct relationship between grinding speed and wheel pressure — together with support and handling systems that move the glass along the machine—ensures smooth, uniformly ground edges while minimizing waste.

Maintenance should not be underestimated. Regular machine and tool maintenance, along with timely replacement of worn grinding wheels, directly affects the final product quality. Only by understanding the overall dynamics of ultra-thin glass grinding can consistent and high-quality performance be guaranteed over time.

Achieving excellent grinding for ultra-thin glass

Lattuada grinders are designed and built to tackle the multiple challenges that can arise during glass grinding, even with ultra-thin sheets. Their adaptability allows them to process thin glass starting from 3 mm up to 100 mm with the TLS series. This enables coverage of a wide range of products and addresses multiple production needs without compromise: it is simply a matter of identifying production requirements and selecting the most suitable model from our range of straight-line grinders.

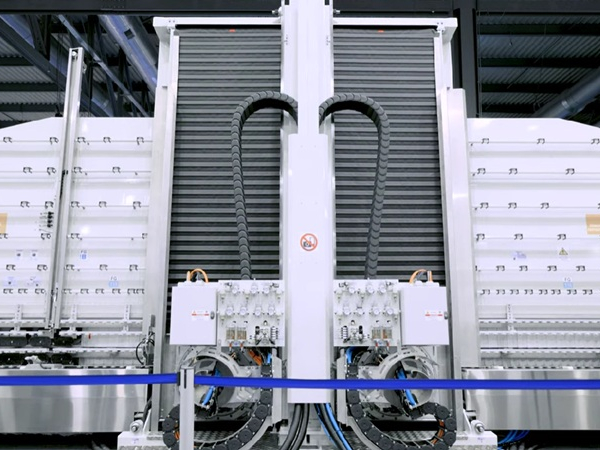

Another distinguishing feature of our grinders is the possibility of full customization. All our machines can be adapted and enhanced to optimize production time, energy consumption, and quality. The integration of advanced systems - such as the A-WR system for fully automatic grinding wheel adjustment and the i-AL system, which combines mechanical, electronic, and software components - enables maximum automation and complete integration with the entire production system, even when handling the thinnest glass sheets.

Innovation and productivity in Lattuada glass grinding

At Lattuada, continuous investment in research and development of technologies to improve glass grinding processes is a priority. Automated regulation and control systems, production management software, and robotic solutions allow us to provide customers with an integrated approach that combines high production speed, precision finishing, and waste reduction. This makes efficient and safe production possible, even with ultra-thin and extremely delicate glass.

With Lattuada straight-line grinders even the most complex production challenges can be addressed while maintaining high quality standards, delivering perfectly ground and finished edges, minimal tolerances, and exceptional transparency—essential elements for any application.

Thin glass grinding without compromise

The combination of configurable machines, advanced support systems, and optimized management of speed and pressure allows excellent results on glass ranging from 3 mm to 100 mm in thickness. Choosing Lattuada means choosing innovation, safety, and productivity, with customizable solutions suitable for every production environment, from small glass workshops to large industrial facilities.

The Lattuada grinders set the global standard in thin glass grinding, transforming complex challenges into efficient, reliable processes, always ensuring superior finishing quality.

600450

600450

Add new comment