Date: 27 August 2025

How is it possible to ensure continuous production, plan for downtimes and quickly and effectively find a solution to problems together with a LiSEC technician? The LiSEC hotline service team processes roughly one hundred customer enquiries on a daily basis and in doing so observes which easily solvable problems occur more frequently. This article contains recommendations from our technicians to help ensure smooth and relaxed machine operation.

The three key elements of prevention: Backup, Backup, Backup

Regular backups play a crucial role in preventing data loss and enabling production to be resumed quickly after downtime.

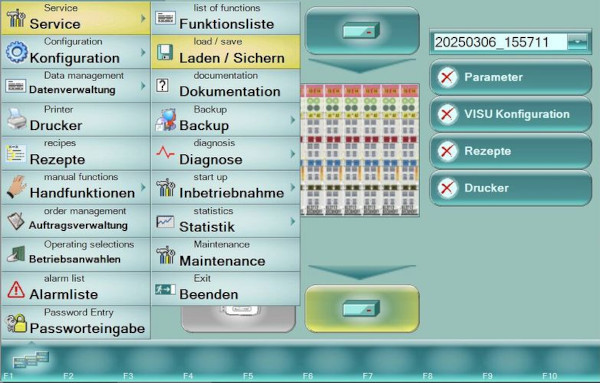

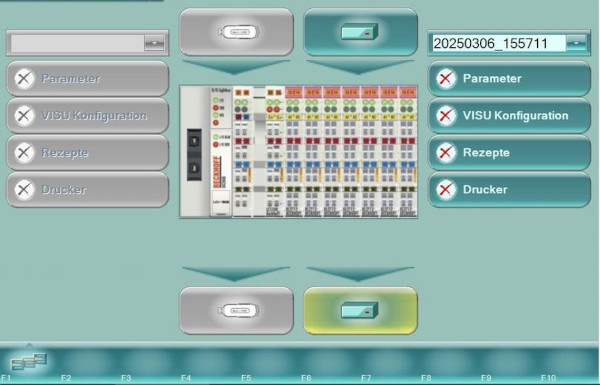

- Parameter backup: We recommend backing up the parameters to an external storage medium on a weekly basis and following each customisation by a LiSEC technician. We have found it useful to save all backup files for a line on USB sticks and label them with the serial number of the respective machine. These USB sticks are collected at a central point, for example in a key box at the end of the line. This means they can be accessed quickly and easily in the event of a malfunction or system downtime.

- Hard disc backup: Risks arising from power failure, hardware failure or accidental deletion mean that the hard disk should also be backed up to a server on a regular basis, ideally every six months, and after every successful update by a LiSEC technician. It only takes around ten minutes to resume production with the help of a LiSEC technician if there is an up-to-date backup.

- Proper shutdown instead of flicking the main switch: If a Beckhoff PC is in use, it must be shut down using the main menu and the "Exit" button. There is otherwise a risk that data, settings or files will be damaged or lost, meaning that it may not even be possible to start the visualisation the next day. We therefore recommend a routine, orderly shutdown of the PC to avoid production interruptions.

- Regularly check the buffer batteries: The buffer battery in the control card ensures that the PLC control programme remains saved when the main switch is switched off. The CPU control loses the programme when the battery is empty and must be reprogrammed. This is indicated by the ER03 or ER04 error messages and the machine cannot be started. A LiSEC technician is able to restore the missing files with minimal interruption to production through an online connection. You should check the buffer batteries of the control cards at regular intervals.

Quality assurance through machine maintenance

The following applies in principle: Regular and thorough cleaning of the machines is essential to prolong their service life and increase production quality.

- Comply with service deadlines: It is essential to carry out regular maintenance in accordance with the operating instructions to ensure the reliability and efficiency of LiSEC machines. Compliance with the prescribed maintenance intervals ensures that potential problems can be recognised and rectified at an early stage. Doing so contributes to smooth operation and greater efficiency in production.

- Keep maintenance logs: Any maintenance performed should be meticulously documented in the maintenance log. These records give the operations manager the ability to track when and what maintenance work has been performed on the machines at any given time. They are also extremely helpful for the LiSEC technician when analysing faults, allowing information about the last replacement, the last cleaning and similar measures to be available immediately. This ensures that problems are resolved quickly and efficiently.

- Regularly check consumables: Ensuring that the necessary consumables, such as cutting wheels and grinding wheels, are always available and in a usable condition is important, especially if they have been in stock for a long time. The availability of the corresponding consumables means that a quick remedy can be found if necessary.

- Sealing machines as a special case: Practise the emergency flushing process! Base material (white) is mixed with catalyst (black) in the sealing machine head to seal ISO units gas-tight. If there is a power failure, base material mixed with catalyst remains in the machine, which hardens in 5 to 10 minutes at normal room temperatures, and in just 3 minutes at high temperatures. This is why there is a device for manual "white flushing" with base material without catalyst. Operators should undergo regular training so that they can quickly respond in an emergency, failing which the hose and nozzle must be completely replaced.

If the worst comes to the worst: Optimum behaviour in the event of error messages

It is of the utmost importance to first read the error message carefully and only acknowledge it once the problem has been clearly recognised in the event of an error. Reconstructing the cause of the fault at a later stage is often difficult and complicates co-operation with the LiSEC technician in order to find a sustainable solution.

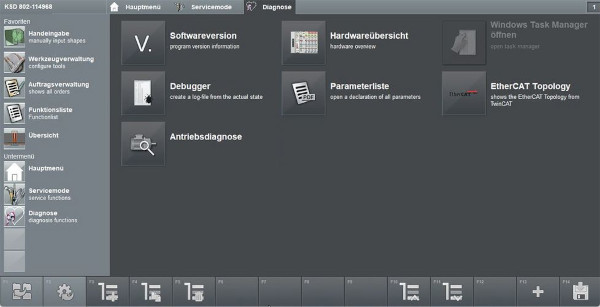

- Document error message and create debugger: Thorough documentation of the machine status during an error is vital for analysing and solving the problem. It would be an advantage to provide a photo of the error message including the visualisation. If it is not possible to take a photo, at least the unique ID number of the error message should be noted. A debugger is ideally created when an error occurs, which logs all current settings, parameters and the machine status. A debugger file is created in the service mode of the visualisation using the diagnostics function.

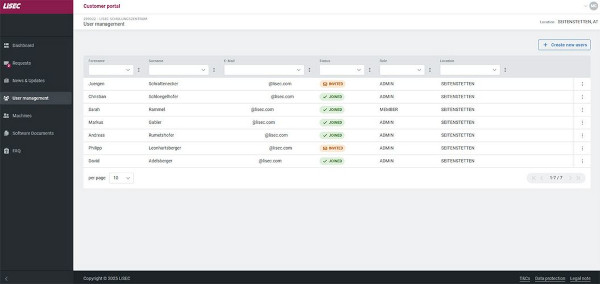

- Report service cases through the MyLiSEC customer portal: The MyLiSEC portal features a structured and user-friendly interface allowing all relevant information such as error messages, screenshots and system data to be recorded. Using the MyLiSEC portal ensures that error reports are forwarded directly to the relevant support team, significantly reducing processing times. The portal also facilitates seamless tracking of the processing status to keep users informed about the progress of their reports at all times.

- Keep contact data up to date: Contact data can be managed by the customers themselves in the MyLiSEC Service Portal. Updated data is especially important when an error is reported by telephone via the hotline. A service case is created by the LiSEC technician with the information received and the serial number of the machine, which is assigned to a customer user. Outdated or incomplete contact data can mean that update emails and queries are sent to people who are not involved in the service case - in the worst case even to former employees. A best practice solution would be to establish a cross-team e-mail address for machines and software that can be accessed by multiple people.

- Fall back on familiar solutions: MyLiSEC features a comprehensive overview of open and completed service requests. This means that the progress and details of service cases can be tracked in detail so that proven solutions can be used when similar problems arise.

Following this recommendation can not only prevent problems, but also significantly reduce any impact of incidents that do occur. Unforeseen events can always occur despite the best preparations. This is why the LiSEC service team is always on hand to provide its customers with comprehensive support that ensures all challenges in flat glass processing can be successfully overcome.

600450

600450

This article is packed with practical advice—especially the emphasis on regular backups and proper shutdown procedures. I really like how LiSEC highlights prevention as the key to smooth operations, since that mindset applies well beyond glass processing. It’s similar to how companies in totally different industries, like Clear Solutions Pool Plastering LLC, rely on consistent maintenance routines to avoid costly downtime and ensure quality results. Preventative care really is universal!