Date: 18 September 2020

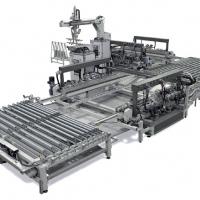

More than ten years ago, or more precisely in October 2008, at Glasstec, RCN SOLUTIONS launched an absolute novelty in lamination: Powerlam, an innovative bag-free, turn-around laminating machine. This system overturned the traditional concept of lamination and was destined to became a must in the glass industry.

Equipped with two conveyors, one for loading and one for unloading, the central body is the heart of the system, a laminating chamber working like a press. It reduces production time, energy and labor costs, since the machine is semi-automatic and requires the assistance of only one operator.

Conceived for high volume production, the real innovation was reducing the production time to less than half in comparison to the traditional laminating process. In 2008, this news was a real bombshell: a revolutionary system suddenly raising the quality of the laminating market to higher levels.

As a matter of fact, Powerlam gave high expectations considering that in less than twenty-three minutes the laminating cycle ends and the glass sheet is ready for distribution.

Powerlam proved to be a real success: the interest and feedback of customers was very important, with several enquiries and sales. Additionally, Powelam revealed to be the most imitated machine with several attempts from other manufacturers.

However, no imitation can match the features of Powerlam because the idea and design belong to RCN. The company is very proud of this technology and it is confident that Powerlam is still the most desired laminating system, offering high performance and viable results.

600450

600450

Add new comment