Date: 12 July 2023

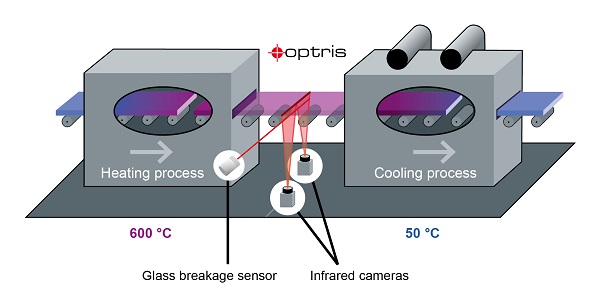

The physical properties of flat glass can be influenced by targeted heat treatment. In the so-called thermal tempering process (is used for single-pane safety glass (SPSG), the glass panes are first put into a furnace and heated uniformly to a temperature of about 650 °C where glass begins to soften.

The hot glass is then moved out of the furnace into a cooling section where it is rapidly cooled by high-pressure blast of air. The quality of the glass mainly depends on a homogeneous thermal treatment, which is ensured by the application of the correct temperature measurement technology.

The challenge of Low-E glass

In order to achieve high energy efficiency in buildings, so-called Low-E glass is standardly used for windows and facade components. Designed as multi-pane insulating glass these windows have a coated side with a very low emissivity.

The low emissivity poses a major challenge for infrared devices which are traditionally measuring the glass temperature from above when the panes moved out of the furnace.

The new Bottom up GIS solves this problem with a new approach. By having two infrared imagers installed underneath the tempering line they always measure the temperature on the non-coated high emissivity side of the glass. IR technology development resulting in those new compact designed imagers made this underneath installation possible which was not thinkable before with old bulky line scanners.

The combination of two VGA imagers with a maximum field of view of 111° results in an excellent 1600 pixels scan line resolution on maximum 4,3 m scan width.

In addition to determining the temperature distribution, the system also calculates the glass surface area.

An ultra-fast CTlaser 4M pyrometer with 90 µs exposure time combined with the digitally controlled lens protection system (DCLP) is a reliable safeguard for both infrared cameras in case of glass breakage. These shutters also significantly increase the maintenance intervals for cleaning the optics and completely eliminate the need for additional and time-consuming blowing of the optics with compressed air.

Optris supplies the bottom up glass inspection system in two versions: the High resolution GIS 640i G7 and the High performance GIS 450i G7. Both systems are pre-assembled for easy installation on glass tempering lines. In addition to the infrared cameras, pyrometer and the shutter systems, the delivery also includes a compact control cabinet with all electronic and control components as well as all necessary cables.

Compared to the line scanner systems often used in the past, the exact alignment of the scan line can be conveniently performed in the software with the camera-based glass inspection system – an exactly mechanical positioning of the system above the oven is not necessary anymore. The effort required for installation and commissioning is therefore reduced to a minimum.

600450

600450

Add new comment