Date: 28 July 2025

Suzhou Huadong Coating Technology Co., Ltd. has been delivering high-quality coated and insulating glass solutions since its establishment in 1993. Based in the Wuzhong Economic Development Zone of Suzhou, the company integrates advanced equipment from global manufacturers, ensuring that their products meet stringent international quality and energy efficiency standards.

With a focus on Low-E glass, insulating glass, and specialty coatings, Huadong Coating serves diverse industries, including construction, transportation, and electronics. Their products have been used in prestigious projects worldwide, making them a trusted name in the industry.

The Challenge: Ensuring Accurate Gas Fill Levels in Insulating Glass Units

As a manufacturer of high-performance insulating glass units (IGUs), Huadong Coating faces the challenge of verifying the gas filling process inside their IGUs without damaging the sealed structure. Maintaining the correct gas concentration is crucial for thermal insulation, energy efficiency, and compliance with international building regulations.

Huadong Coating has a gas measurement device Sparklike Handheld, but it was limited to testing single-cavity IGUs, meaning double glazing. With evolving industry requirements, they needed a solution capable of measuring multi-cavity IGUs, especially those with multiple layers of Low-E coatings. Ensuring accurate gas retention in these advanced glass structures was becoming increasingly important to meet global energy efficiency regulations.

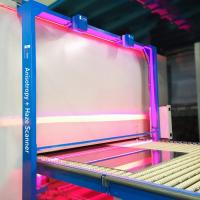

The Solution: Sparklike Laser Portable for Non-Invasive Gas Measurement

To address this challenge, Huadong Coating integrated the Sparklike Laser Portable into their quality control process. This advanced device enables precise gas fill verification for both single and multi-cavity IGUs, ensuring compliance with the latest energy efficiency standards.

In a recent demonstration video, a Huadong Coating representative highlighted the reasons for choosing Sparklike Laser Portable:

- Accurate Measurements: The device ensures reliable readings of gas fill levels, improving product quality control. According to ift Rosenheim’s test results, Laser Portable fulfills the EN 1279-3 requirements for measurement accuracy.

- Non-Invasive Testing: Unlike traditional methods, the IGUs remain intact during testing, reducing waste and improving process efficiency.

- Capability for Multi-Cavity IGUs: The device can measure gas levels in multi-cavity glass units, which was a major improvement over their previous solution.

- Ease of Use and Portability: The device allows for quick and easy measurements across various production stages.

The Impact: Enhancing Quality Assurance and Customer Confidence

By adopting Sparklike Laser Portable, Huadong Coating has achieved:

- Optimized Production Efficiency: Quick and non-invasive gas filling process measurements streamline quality control processes.

- Improved Product Reliability: Precise gas content verification ensures IGUs maintain their insulating properties over time.

- Stronger Customer Trust: Verified gas levels enhance Huadong Coating’s reputation for high-quality insulating glass solutions.

Leading the Future of Insulating Glass Technology

With a commitment to innovation and quality, Huadong Coating continues to advance its production capabilities while meeting global energy efficiency standards. By leveraging Sparklike Laser Portable, they ensure their products comply with the latest near-zero energy building requirements and industry expectations for multi-layer Low-E glass with advanced gas retention properties.

For manufacturers seeking a reliable, non-invasive gas measurement solution, Sparklike Laser Portable proves to be an essential tool for ensuring IGU performance and compliance with gas filling process validation.

Contact us to learn how Sparklike devices support your insulating glass quality control.

600450

600450

Add new comment