Author: Mauri Saksala | Glaston

Source: glastory.net

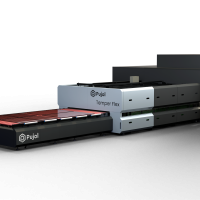

Glass tempering has traditionally relied on skilled manual labor to maintain quality. However, today’s labor shortages and industry challenges are driving the need for automation. One area already delivering measurable gains is intelligent batch building – optimizing how different glass sheets are arranged on the furnace bed. With today’s AI-based robotized loading solutions, glass processors can save time, reduce energy use and handle a wide mix of glass types with remarkable precision. But what does this mean in practice?

Industry data reveals a typical loading bed utilization rate of just 37%. Added with significant furnace idling and missed loadings, this underutilization wastes production capacity, energy and money. For example, improving bed utilization from 25% to 45% can easily save EUR 40-80,000 annually per furnace, only by saved electricity.

Improving the utilization rate will additionally increase the productivity making possible to sell more production.

How AI-based algorithms optimize tempering

While robotics in glass processing isn’t new, integrating AI-based algorithms for batch building opens new doors for productivity gains.

AI algorithms dynamically adjust both batch arrangements and process parameters by analyzing production flow, furnace properties and historical process data. When integrated with robotized loading, this enables highly optimized bed utilization – with minimal empty slots. The result? Improved throughput, cost savings and quality.

Balancing automation and manual flexibility

By embracing today’s advanced solutions, including automated batch building, glass processors can achieve up to 90% automation in tempering. Still, full automation isn’t yet practical for every production environment. Maintaining the possibility to manually handle unique or complex glass types or special production situations remain essential.

That’s why a hybrid approach is key to combining efficiency with the flexibility to adapt to varying demands.

Technology shaping the future of tempering

Automation powered by AI is transforming flat glass tempering. To dive deeper into one of the key innovations driving this change – automatic loading – download the full presentation.