Authors: Changyu Qiu1,*,Hongxing Yang 2 and Kaijun Dong 1,*

1Guangzhou Institute of Energy Conversion, Chinese Academy of Sciences, Guangzhou 510640, China

2Department of Building Environment and Energy Engineering, The Hong Kong Polytechnic University, Hong Kong, China

*Authors to whom correspondence should be addressed.

Buildings 2025, 15(12), 2038; MDPI

DOI: https://doi.org/10.3390/buildings15122038

Submission received: 9 May 2025 / Revised: 27 May 2025 / Accepted: 5 June 2025 / Published: 13 June 2025

(This article belongs to the Special Issue Renewal and Retrofit in Buildings: Toward a Sustainable and Low-Carbon Future)

Abstract

In the context of global warming, building transformation takes on a dual responsibility to be more energy-efficient and sustainable for climate change mitigation and to be more climate-resilient for occupants’ comfort. The building energy retrofitting is an urgent need due to the large amount of existing building stock. Especially in high-rise and high-density cities under a subtropical climate, like Hong Kong, existing buildings with large glazed façades face the challenges of high energy consumption and overheating risks. An advanced glazing system, namely the vacuum insulating glazing (VIG), shows the potential for effective building envelope retrofitting due to its excellent thermal insulation ability. Yet, its performance for practical applications in the subtropical region has not been investigated. To enhance the energy performance and thermal comfort of existing high-rise buildings, this study proposed a novel retrofitting approach by integrating the VIG into the existing window system as secondary glazing. Field experiments were conducted in a commercial building in Hong Kong to investigate the thermal performance of the VIG retrofit application under real-world conditions.

Furthermore, the energy-saving potential and thermal comfort performance of the VIG retrofit were evaluated by building energy simulations. The experimental results indicate that the VIG retrofit can effectively stabilize the fluctuation of the inside glass surface temperature and significantly reduce the heat gain by up to 85.3%. The simulation work shows the significant energy-saving potential of the VIG retrofit in Hong Kong. For the VIG retrofit cases under different scenarios, the energy-saving potential varies from 12.5% to 29.7%. In terms of occupants’ thermal comfort, the VIG retrofit can significantly reduce the overheating risk and improve thermal satisfaction by 9.2%. Due to the thermal comfort improvement, the cooling setpoint could be reset to 1 °C higher without compromising the overall thermal comfort. The average payback period for the VIG application is 5.8 years and 8.6 years for the clear glass retrofit and the coated glass retrofit, respectively. Therefore, the VIG retrofit approach provides a promising solution for building envelope retrofits under subtropical climate conditions. It not only benefits building owners and occupants but also contributes to achieving long-term climate resilience and the carbon neutrality of urban areas.

1. Introduction

Nowadays, global climate change has manifested its catastrophic effects in the form of increasing frequency and intensity of extreme weather events, such as the most severe heatwave in China, the heaviest rainfall in the United Arab Emirates, and the rare flooding in the Sahara Desert [1,2]. With the average global temperature record reported at 1.55 ± 0.13 °C above pre-industrial levels in 2024, it poses an ever-greater urgency to mitigate greenhouse gas (GHG) emissions and develop a sustainable environment for achieving the long-term goal of the global warming limit by the Paris Agreement [3]. The building sector is a major contributor to global warming, accounting for 40% of energy use and 30% of carbon emissions worldwide [4]. Therefore, the decarbonization of buildings plays a crucial role in achieving long-term carbon neutrality and fostering a sustainable future.

Many countries have updated their national building energy codes to set high standards of energy efficiency and environmental impact [5]. For instance, the revised Energy Performance of Buildings Directive mandates that all new buildings in the European Union must meet the “zero emission building” standard by 2030 [6]. However, most of those building codes mainly focus on promoting energy-efficient and sustainable development in newly constructed buildings. Since 80% of the building stock in 2050 will consist of buildings presently in existence [7], the existing buildings will dominate future emissions in the building sector. The current retrofit rate of existing building stock is estimated as 1% per year, which should be significantly increased to 2.5–5% to achieve the carbon emission reduction target of the Paris Agreement [8]. Therefore, it is an urgent need to adopt effective building energy retrofitting to improve energy performance and sustainability, especially in developed high-density urban areas.

In Hong Kong, there are over 16,000 high-rise buildings and over 42,000 buildings in total [9]. As a result, the building sector accounts for approximately 90% of total electricity consumption and contributes 60% of carbon emissions [10]. Due to the subtropical climate, most commercial buildings have to maintain air conditioning from March to November to meet the indoor thermal comfort requirements [11]. Moreover, the glass-dominated curtain walls, which are quite common in many high-rise commercial buildings, often lead to high cooling demand and thermal discomfort [12]. With the intensive trend of global warming, existing buildings will suffer the increasing risk of overheating, particularly for high-rise buildings with high levels of window-to-wall ratio (WWR) [13]. Therefore, retrofitting on the windows and glazed curtain walls of existing buildings becomes increasingly important. Effective retrofitting measures offer significant potential for energy saving as well as carbon emission mitigation and creating a more resilient and comfortable indoor environment in future climate scenarios [14].

To improve the energy performance of existing buildings with large glazed façades, the retrofitting options include applying coatings or solar films, upgrading to multi-glazing windows, and replacing with advanced window technologies [15,16,17]. Pereira et al. [18] evaluated the energy-saving potential and environmental impact of three different solar control films applied to the existing window in the Mediterranean climate. The simulation results indicated that the solar control film with a higher light-to-solar gain ratio can obtain a higher energy saving. Moreover, the retrofitting solution of additional solar films shows a lower life cycle energy (LCE) compared to the full replacement of the existing window with a new one with a lower U-value, where the LCE of the latter one is 1.5 times larger than the LCE of solar film retrofitting. Huang et al. [19] conducted a series of simulation studies to investigate the thermal performance of double glazing with clear glasses and double glazing with low-e coating in cooling-dominant regions, including Hong Kong, Singapore, Houston, and Miami. Compared to the single glass, the window heat gain can be reduced by 50% by the low-e glazing and up to 20% by the double glazing. Similarly, Moghaddam et al. [20] conducted simulation work to investigate the energy and thermal comfort performance of the low-e window films applied on double-glazed windows in the cold climate of Sweden.

By replacing the common double-glazed clear windows with the double-glazed low-e windows of a historical building, the window heat loss in winter and heat gain in summer decreased by 36% and 35%, respectively, resulting in a 6% annual savings on building energy consumption and a 3% reduction of the thermal dissatisfaction hours. El-Darwish and Gomaa [21] proposed a building envelope retrofitting strategy for public buildings in the hot arid climate, including retrofitting measures like window replacement, solar shading, and enhancement of airtightness and wall insulation. The simulation results showed that the Argon-filled double glazing with low-e coating could save the average energy consumption by 8%, which is a more effective retrofitting measure than the airtightness and wall insulation improvement. Various advanced window technologies have been explored for building envelope retrofitting, such as building-integrated photovoltaic (BIPV) windows [22], polymer dispersed liquid crystal film (PDLC) glazing [23], and phase change material (PCM)-filled windows [24]. However, these retrofitting solutions typically involve substantial initial and installation costs, as the associated retrofit projects often require the full replacement of existing window systems or glazed façades. Moreover, the considerable thickness and weight of these complex, multi-layered window systems can pose structural and practical challenges, limiting their applicability in existing buildings.

In recent years, the advanced vacuum insulating glazing (VIG) technology has been regarded as an emerging glazing product in the Chinese glass market due to its distinctive characteristics of thermal preservation, soundproofing, lightweightness, and resistance to condensation [25]. A vacuum glazing consists of two glass panes separated by a narrow vacuum space, which are supported by an array of small pillars against the atmospheric pressure. The vacuum gap can minimize the conductive and convective heat transfer through the glazing. Additionally, a low-emissivity (low-e) coating deposited on the inner surface of the vacuum glazing can further reduce the heat transfer due to radiation.

Extensive studies were conducted to investigate the thermal performance and energy-saving potential of the VIG applications. Fang et al. [26] measured the overall heat transfer coefficient (U-value) of two VIG samples with clear glass panes to be 1.21 ± 0.10 W/m2K and 1.28 ± 0.11 W/m2K through the guarded hot box experiments. The thermal properties of the VIG with different low-e coatings were also experimentally determined, where the U-value at the center-of-glazing area ranged from 0.87 ± 0.07 W/m2K to 1.07 ± 0.09 W/m2K [27]. To further improve the thermal insulation performance of the VIG, researchers proposed hybrid vacuum glazing (HVG), which combines a double vacuum glazing (DVG) and a third glass with an air cavity [28], and the triple vacuum glazing (TVG) consisting of three glasses and two vacuum gaps [29,30].

The simulation results indicated that the HVG enhanced the thermal insulation performance of the DVG due to the integration with the third glass pane and extra air gap [28]. The U-value of HVG was reported as 0.64 W/m2K, while the U-value of DVG was 0.85 W/m2K. The heat transfer of the proposed TVG with various low-e coating configurations was simulated using a finite volume model (FVM) [30]. It was found that the total U-value of the TVG was only 0.26 W/m2K when the low-e coatings were adopted on four internal glass surfaces. The thermal properties of two configurations of the air-vacuum layered triple-glazed window (IVM) were reported by Fang et al. [31]. The simulation results indicated that setting the VIG facing indoors has a lower U-value, while the structure of the VIG facing outdoors has a higher solar heat gain. In terms of the energy-saving potential, previous studies have mainly focused on the energy performance of the VIG in cold climate applications.

In Dublin, Ireland, Ghosh et al. [32] measured the thermal and daylight performance of a VIG using an outdoor test cell. The VIG showed the potential to decrease the heat loss by 53% compared to common double glazing with the same dimensions, while the daylighting illuminance was not compromised. In Incheon, Korea, Cho and Kim [33] reported that the application of VIG in office buildings reduced the heating and cooling consumption of buildings by 2.46% compared with the case using the double glass window with Argon-filled and low-e coating. Similarly, Baek and Kim [34] simulated the annual energy performance of the VIG applications in a residential building in Seoul, Korea. The annual cooling and heating energy demand of the VIG case was calculated to be 1308.8 kWh, which was much lower than that of the double, triple, and quadruple glazing cases.

The previous research has demonstrated the excellent thermal performance of the VIG through simulations and laboratory tests. However, few studies have conducted field-based evaluations of the thermal performance of the VIG, especially for cases under subtropical conditions. Moreover, the thermal comfort of the VIG applications in real-world practice still needs further investigation. On the other hand, conventional glazed façade retrofitting strategies (i.e., full replacement of window or curtain wall) are often costly and time-consuming, involving occupant relocation [35]. Hence, non-destructive measures are preferable as they are more cost-effective for building owners and less disruptive to occupants, particularly for window retrofits in existing high-rise buildings. It is worth noting that the VIG is not only superior in terms of thermal performance but also considerably thinner than conventional double glazing with a gas-filled cavity [36]. Therefore, the VIG is well-suited for space-constrained retrofitting scenarios for energy-efficient building envelope renovation [37].

Based on the literature review, the following research gaps are identified: (1) What is the thermal performance of the vacuum glazing in real-world applications? (2) How can the vacuum glazing improve thermal comfort? (3) What is an affordable and effective retrofitting strategy on large glazed façades for high-rise buildings in subtropical regions? To address these research gaps, this study proposes a non-destructive retrofitting initiative to install the VIG on the existing window frames without replacing the existing windows or changing the building envelope appearance. The aim is to investigate the energy performance, thermal comfort performance, and economic benefits of this novel retrofitting measure based on the VIG application. On-site field experiments and numerical studies have been conducted to evaluate the performance of the VIG retrofitting case in a high-rise commercial building in Hong Kong.

Based on the results, an economic analysis was conducted to identify the benefits and payback periods under different VIG retrofitting scenarios. Section 2 introduced the proposed VIG retrofitting approach and the methodology of the field experiments, as well as the numerical simulations. In Section 3 and Section 4, the experimental results of the VIG retrofitting under different climate conditions and the simulation results of the energy performance of various VIG retrofitting scenarios were analyzed in detail, respectively. Section 5 discussed the effect of the VIG retrofitting on thermal comfort and potential energy savings due to thermal comfort improvement. In Section 6, the economic analysis was conducted. Section 7 concludes the main findings of this study. This study provides a solid understanding of the energy performance and thermal comfort improvement of the vacuum glazing in real-world applications. The VIG retrofitting provides a promising solution for the transition of existing high-rise, high-energy-demand buildings to energy-efficient and climate-resilient buildings under future climate change.

2. Methodology

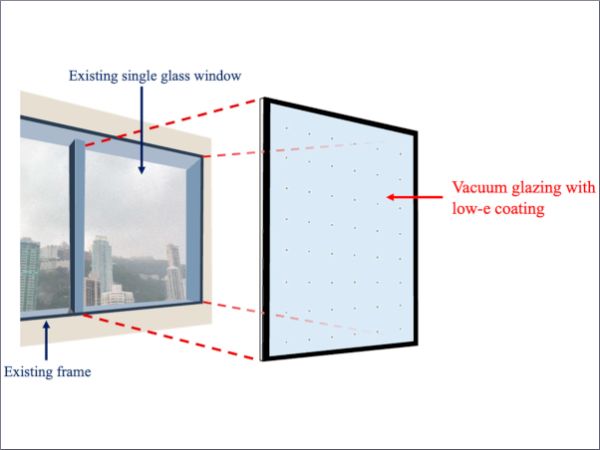

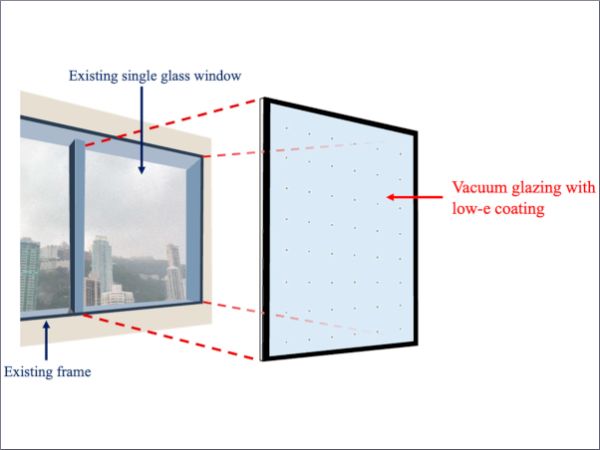

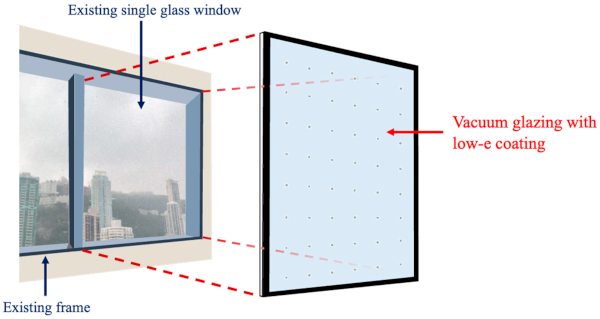

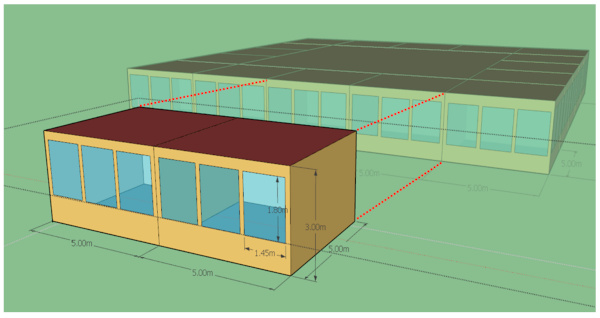

To upgrade inefficient windows without major building renovations, this study employs a secondary glazing approach for the VIG retrofit applications. As illustrated in Figure 1, the VIG systems with low-e coating were manufactured to a size that can precisely fit into the existing window frames. The retrofitting work, which was conducted by South Star Glass Limited, installed the VIG onto the interior side of the existing single glass window. The VIG products were provided by Luoyang LandGlass Technology Co., Ltd. (Luoyang, China). The VIG was attached to the existing window glass with warm edge spaces as a secondary glazing. Figure 2 shows the structure of the VIG retrofitted window as a triple glazing unit with an external air gap and an internal vacuum gap. By deploying this fast and cost-effective retrofitting method, the VIG retrofitted window systems can enhance the thermal performance of existing windows while preserving aesthetics and daylight availability.

2.1. Setup of Field Test Bedding

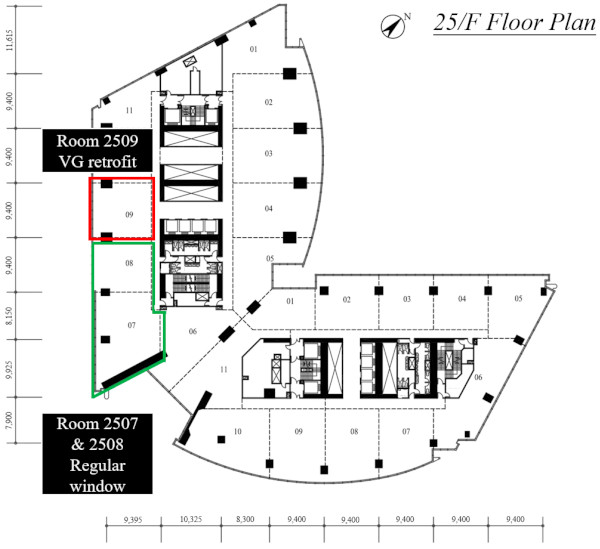

The field tests were conducted in two rooms of a high-rise commercial building in Hong Kong. Figure 3 shows the layouts of the 25/F floor plan, where the numbers from 01 to 11 represent individual office rooms in the west wing and east wing. The two test rooms are located on the west wing of 25/F, i.e., Room 2509 with the VIG retrofit and Room 2507/2508 (a combined room) with the existing windows without retrofit. There is no shading from surrounding buildings on the 25/F of the southwest façade.

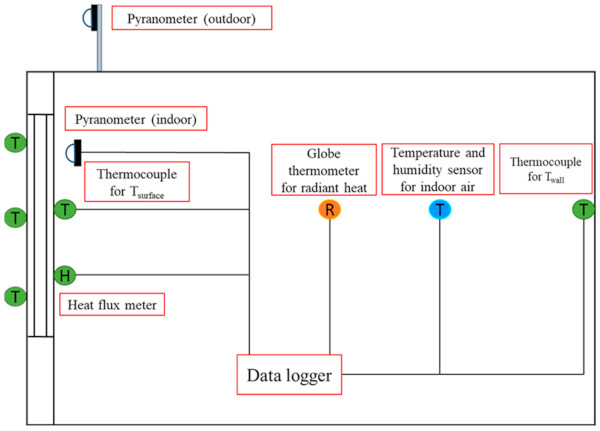

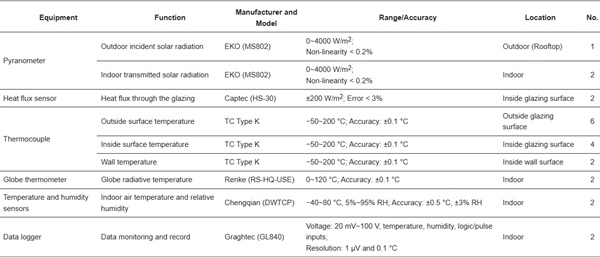

Figure 4 illustrates the details of the experimental setup. Sensors are installed in the two rooms for comparisons of thermal comfort performance between the windows with and without the VIG retrofit. One pyranometer was installed on the rooftop facing southwest to monitor the outdoor incident solar radiation exposed on the external wind surfaces. For each room space of the two rooms, there are three thermocouples attached to the outside surface of the window to measure the outside surface temperatures of the glazing. There are also several thermocouples in each room space for measuring the inside surface temperatures of the window glazing, indoor air temperatures, and wall surface temperatures. One heat flux meter was mounted on the inside surface of the glazing in each room to monitor the heat flux through the glazing area. A pyranometer was set in each room facing outside to measure the transmitted solar radiation. Additionally, one globe thermometer and one temperature and humidity sensor were set to monitor the indoor radiative temperature, indoor air temperature, and relative humidity in each room space. A list of the key instruments is shown in Table 1.

Table 1. The key instruments of the measurement system.

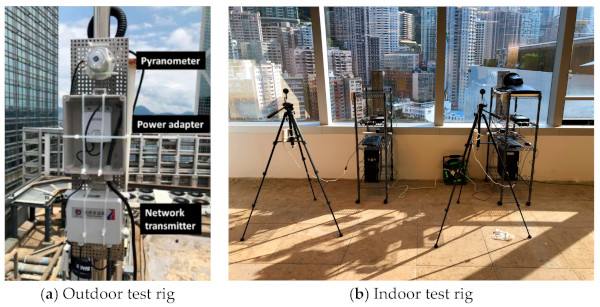

Figure 5 shows the outdoor equipment on the rooftop and the indoor test rigs. One pyranometer was installed on the rooftop with a network transmitter so that the measured data could be uploaded to the online experiment platform simultaneously. For each indoor test rig, one indoor pyranometer, one thermocouple for the inside surface temperature, one globe thermometer, and one temperature and humidity sensor were set up and connected to the data logger GL840. The measured data were monitored and controlled via a PC using their application software. Each PC has WLAN access to the internet. Hence, the remote monitoring of the data acquisition system can be achieved by using a remote control program. To ensure the test reliability and minimize the measurement errors, all sensors were calibrated before the experiments. The temperature sensors were compared to an NIST-traceable thermometer at three known temperature points: 0 °C, 25 °C, and 100 °C. Pyranometers and heat flux sensors were calibrated by the manufacturers. The measurement range, accuracy, and error of the key instruments in the field tests are shown in Table 1.

2.2. Numerical Simulation

In order to study the energy-lighting-thermal comfort performance of the novel retrofitted glazing window, a detailed simulation of the annual performance for different orientations has been conducted. In this numerical study, the EnergyPlus (Version 23.1.0) and Berkeley Lab WINDOW software (Version 7.8.71) packages were employed. The Berkeley Lab WINDOW was used to construct the vacuum glazing retrofit application layer by layer and then to generate an input file for the EnergyPlus model, which contains the material properties of each layer and the spectral data of the glazing. EnergyPlus is a whole building energy simulation program, which can model both energy consumption and occupants’ thermal comfort.

As shown in Figure 6, the simulation model consists of two identical office rooms, which represent the cases with and without the vacuum glazing retrofit. The dimension of each office is 5 m × 5 m × 3 m (L × W × H). Only one wall of the office room was exposed to the outdoor environment, while the other walls were defined as internal surfaces/partitions within the air-conditioned space. There are three separate windows with the same dimensions of 1.45 m × 1.8 m on the exterior wall. The external wall was constructed in compliance with the building code in Hong Kong [38]. Table 2 lists the key thermal properties of the multi-layer external wall. An air-conditioning system was applied in the rooms for cooling. In EnergyPlus, a gross rated cooling coefficient of performance (COP) was set as 2.78 to specify the efficiency of the air-conditioning system at operating conditions.

Therefore, the cooling energy consumption can be determined based on the demand. The thermostatic zone control was set as dual setpoints with a cooling setpoint of 24.5 °C. The fresh air supply is set as 0.02 m3/s. The office occupancy time is from 9:00 to 19:00 on weekdays and from 11:00 to 19:00 on Saturdays. The internal load of the office is 18 W/m2 including lighting and electric equipment. To evaluate the effect of the retrofit on the lighting consumption, a continuous dimming control strategy was applied to operate the lighting system, making it extremely sensitive to the variation of the available indoor daylighting. The occupants’ thermal comfort model, which is based on the ASHRAE 55 model, was employed to calculate the PMV (predicted mean vote) and PPD (predicted percentage of dissatisfied) for each time step. The weather data file for the location and climate is the typical meteorological year (TMY) data in Hong Kong. Simulations could be conducted for different orientations, i.e., south (S), west (W), north (N), and east (E).

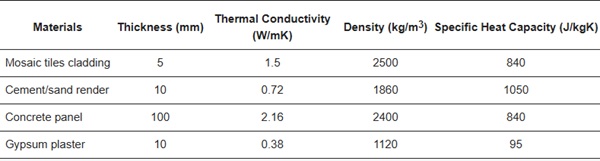

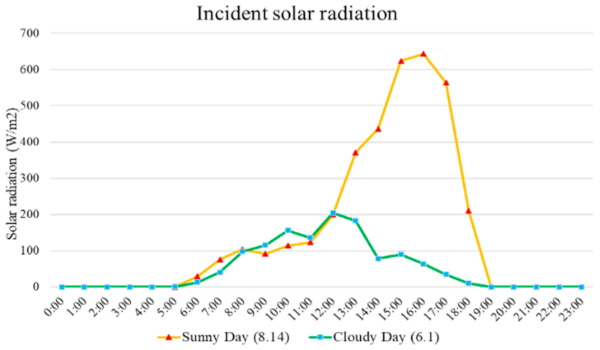

Table 2. Key properties of the multi-layer external wall.

In order to investigate the thermal performance of the vacuum glazing retrofit (VIG) for different applications, two cases were studied to compare the window system with and without the VIG retrofit. For Case 1, which represents the most common window types in Hong Kong, a single-pane clear glass was selected as a baseline for comparison purposes. For Case 2, a single-pane coated glass was identical to the window glazing adopted in the building with a grey coating on the inner surface. Table 3 shows the properties of all the possible glazing systems, including visible light transmittance (Tvis), solar transmittance (Tsol), overall heat transfer coefficient (U-value), and solar heat gain coefficient (SHGC).

Table 3. Key properties of the different glazing systems.

To validate the energy consumption simulations through EnergyPlus for potential annual energy and economic analysis of the VIG retrofitting windows, one-year power meter data of the air-conditioning recorded by the energy management system of the building were collected and processed. The accumulative energy consumption of the air-conditioning system from 1 May to 30 June is also selected for validation purposes. For the annual energy consumption, the measurement data were 102.95 kWh/m2 per floor area, while the simulation result was 109.0 kWh/m2 per floor area. For the total energy consumption in the two months, the measured and predicted results were 22.61 and 21.58 kWh/m2 per floor area, respectively. Comparing the simulation results and the real energy consumption in this building, it can be seen that the deviations are within ±6%. The simulation results agree well with the measured data, so that the simulation model can be used for future energy consumption predictions.

2.3. Thermal Comfort Indices

To evaluate the thermal comfort performance of the VIG retrofit, two indices are used in this study, namely the predicted mean vote (PMV) [39] and predicted percentage of dissatisfied (PPD) [40]. The PMV model is widely used by many international standards [41,42]. It quantifies the level of thermal comfort of the indoor environments by predicting the average thermal sensation of a large group of people based on human activities and measurable environmental parameters. The 7-point scale identifies the level of thermal comfort as follows: +3 (hot); +2 (warm); +1 (slightly warm); 0 (neutral); −1 (slightly cool); −2 (cool); and −3 (cold). Within the recommended PMV range of ±0.5, the indoor environment can be defined as the comfort zone. The PPD index provides an estimation of the percentage of people who would feel dissatisfied with the indoor thermal conditions. It can range from 5% to 100%, where 10% of PPD represents the recommended comfort zone (−0.5 < PMV < +0.5) and 5% of PPD represents the thermal neutrality when the PMV equals zero. In this study, both indices were determined by the building energy simulation model.

2.4. Economic Analysis

By considering the time value of money, a dynamic payback period calculation approach was adopted to measure how long it takes to ‘pay for itself’. To make it convenient, a cash flow diagram is used for economic analysis, where outflows are negative and inflows are positive. The net cash flow value (NCF) refers to the difference between cash inflow value (CIV) and cash outflow value (COV).

![]()

Due to the increase in energy prices and inflation, the net cash flow should increase year by year. The net cash flow in the future (NCFn) can be calculated as

![]()

where NCF is the net cash flow value at the present (HK$/year), i is the annual inflation rate (the discount rate), and n is the project lifetime (years). An annual inflation rate of 2.5% was used in this research. The payback time (PBT) is the number of years it takes for the cumulative annualized savings to become positive:

where PBT is the calculated payback time (years) and N represents the year when the cumulative cash flow exceeds the initial investment.

3. Experimental Results and Discussion

The field experiment started on 24 May. The experimental data from 25 May to 15 August are shown in Figure 7. The data collection of glazing surface temperature and heat flux was interrupted from 2 June to 7 June due to window maintenance work in the rooms. Therefore, the environmental data measured during that period were also omitted from the data analysis. It can be found that the inside surface temperature of the VIG retrofit was significantly lower than that of the single glass. The maximum inside surface temperatures for the VIG retrofit and the single glass were 29.9 °C and 50.2 °C, respectively. Meanwhile, less solar radiation and thermal heat were transferred through the VIG retrofit. In terms of the transmitted solar radiation and heat flux through the glazing, the maximum values for the VIG retrofit application were 22.4 W/m2 and 20.7 W/m2, respectively, while the maximum values for the single glass were 40.8 W/m2 and 138.7 W/m2, respectively.

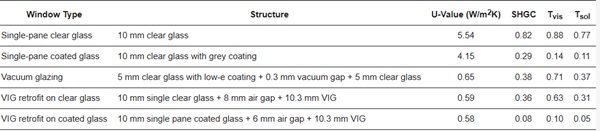

August 14th and June 1st were selected as two typical days, one sunny and one cloudy days for August and June in Hong Kong, respectively, for data analysis in this report. The average incident solar radiation in each hour on these two days is shown in Figure 8. The amount of solar radiation on sunny days was much higher than that on cloudy days. The maximum incident solar radiation on the sunny day was 643.2 W/m2 on the vertical outside wind surface, while the maximum incident solar radiation on the cloudy day was 204.4 W/m2. The average incident solar radiation of the daytime on the sunny day and cloudy day was 275.8 W/m2 and 94.1 W/m2, respectively.

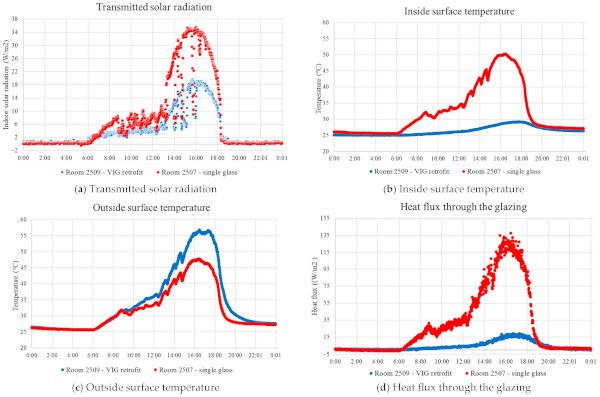

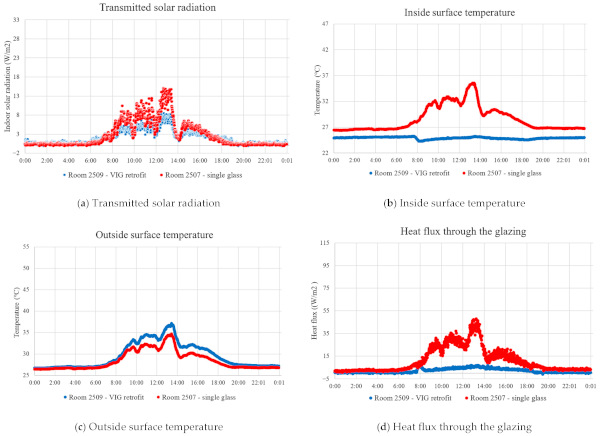

3.1. Case 1: Sunny Day

Figure 9 shows the experimental data from the tests on the sunny day. It can be seen that the transmitted solar radiation through the VIG retrofit was less than that through the single-pane coated glass, especially when outdoor solar radiation was higher than 100 W/m2. This phenomenon is more significant as the added vacuum glazing with low-e coating decreases the solar radiation transmittance. Consequently, the solar heat gain control ability is enhanced by the VIG retrofit application. The maximum transmitted solar radiation was 19.7 W/m2 for the VIG retrofit application and 35.5 W/m2 for the single glass. The average transmitted solar radiation from 7:00 to 18:00 of the two glazing systems was 8.1 W/m2 and 11.9 W/m2, respectively. When the outdoor solar radiation was more than 100 W/m2, the ratio of the transmitted solar radiation of the VIG retrofit over that of the single glass was around 0.49 to 0.67.

As shown in Figure 9b,c, the thermal responses of the VIG retrofit and the single glass were quite different. For the existing single-pane coated glass, the inside and outside surface temperatures showed a similar trend to the transmitted solar radiation. And the inside surface temperature was slightly higher than the outside surface temperature. The ranges of the inside and outside surface temperatures were 25.5 °C to 50.2 °C and 25.6 °C to 47.8 °C, respectively. The grey coating on the inner surface of the existing glazing absorbs a certain amount of solar radiation, which is then transferred to both indoor and outdoor spaces through convective heat transfer and long-wave radiation. Therefore, the heat flux through the single-pane coated glass was highly responsive to the incident solar radiation.

In contrast, the inside surface temperature of the VIG retrofit is quite stable. However, the outside surface temperature is much higher compared with the single glass. As aforementioned, the temperature of the grey coating is much higher than that of the adjacent components, so that thermal heat from the coating layer is transferred both inward and outward. Because of the excellent thermal insulation ability of the VIG, the heat transfer from the grey coating is hardly towards the indoor space. Consequently, more heat will be transferred to the outside surface. The inside and outside surface temperatures of the VIG retrofit were in the range of 24.9 °C to 29.2 °C and 25.6 °C to 56.9 °C, respectively. The average inside surface temperature of the VIG retrofit was only 26.4 °C, which is much lower than that of the single-pane coated glass at 34.3 °C. As shown in Figure 9d, the heat flux through the VIG retrofit was also more stable than that of the single glass. The maximum heat flux through the VIG retrofit was only 19.4 W/m2, while the heat flux of the single glass could reach up to 137.5 W/m2. The average heat flux through the VIG retrofit was significantly lower than that of the single glass, which were 4.3 W/m2 and 29.2 W/m2, respectively. Therefore, the reduction of average heat flux reaches 85.3% by the VIG retrofit application on the sunny day.

3.2. Case 2: Cloudy Day

Figure 10 shows the experimental data of the tests on the cloudy day. A similar phenomenon can be observed when experimental data on the sunny day and cloudy day are compared. For the single-pane coated glass, the transmitted solar radiation, inside and outside surface temperature, and the heat flux were highly responsive to the outdoor environment. For the VIG retrofit application, the inside surface temperature and heat flux were stable because the vacuum glazing can significantly reduce the heat transfer from the outdoor to indoor space. The outside surface temperature of the VIG retrofit was also higher because of the good heat insulation characteristics of the vacuum glazing.

It can be seen that the weather conditions had a significant effect on the single-pane coated glass performance but little on the VIG retrofit performance. The maximum transmitted solar radiation through the single glass on the cloudy day was 15.1 W/m2, about half of that on the sunny day. The maximum inside and outside surface temperatures of the single glass on the cloudy day were 35.6 °C and 34.7 °C, respectively, which were nearly 10 °C lower than the highest value measured on the sunny day. The heat flux through the single glass on the cloudy day reached up to 47.8 W/m2, which is much less than that on the sunny day at 108.0 W/m2. The average heat gain reduction on cloudy days was 80%.

By contrast, the differences in the performance of the VIG retrofit application were not significant under different weather conditions, especially for the inside surface temperature and the heat flux through the glazing. The variation of the inside surface temperature was within 2.4% due to the excellent insulation performance of the VIG retrofit. The maximum heat flux through the VIG retrofit was 8.8 W/m2. The summarized data of the experiments are shown in Table 4. The results indicate that the VIG retrofit can effectively stabilize the inside surface temperature and significantly reduce the heat gain of the window, so that less cooling energy consumption is required. Furthermore, since the inside surface temperature of the VIG retrofit remains stable at the time of occupancy, the thermal comfort of occupants is expected to be improved, which could provide the opportunity to increase indoor air temperature settings for air conditioning, thereby reducing cooling energy consumption.

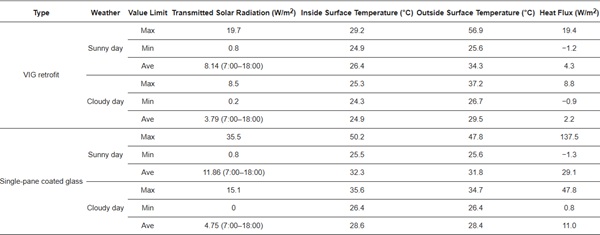

Table 4. Summary of the experimental data on the sunny day and cloudy day.

4. Numerical Simulation Results and Discussion

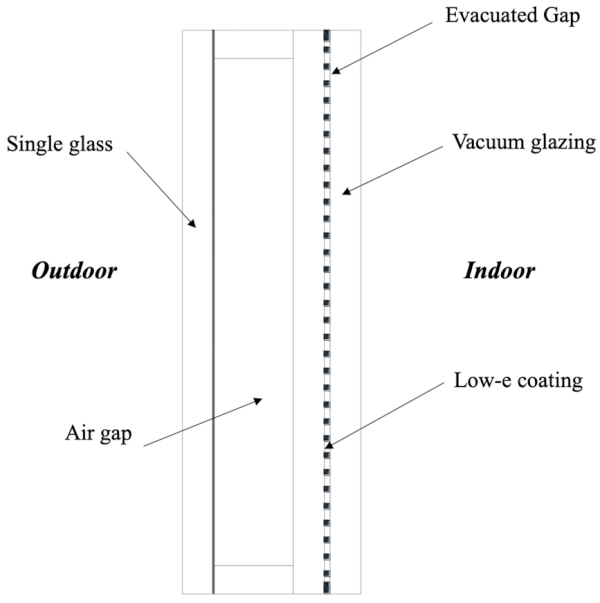

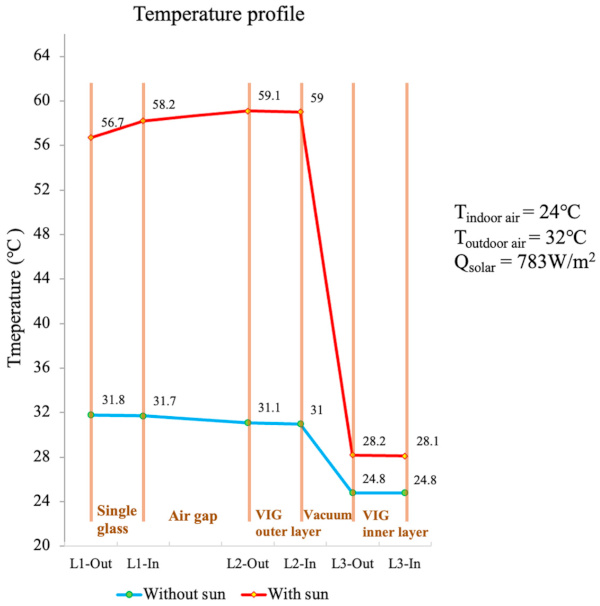

The energy performance of the VIG retrofit application highly depends on the thermal response of the vacuum glazing. To investigate the heat transfer behavior of the VIG under the standard test conditions, the Berkeley Lab WINDOW was used to calculate the temperature profile of the VIG retrofit application layer by layer, as shown in Figure 11. The simulations of different scenarios were conducted under the NFRC 100-2014 summer conditions, where the outdoor design air temperature is 32 °C, the indoor design air temperature is 24 °C for air-conditioning space, and the solar radiation is 783 W/m2.

When there is no solar radiation, the surface temperature gradually decreases from 31.8 °C on the outer surface of the single glass to 31.0 °C on the inner surface of the first layer of the vacuum glazing. Then, it dramatically decreases to 24.8 °C due to the thermal insulation of the vacuum gap.

When solar radiation is exposed, the surface temperature gradually increases from 56.7 °C on the outer surface of the single glass to 59.1 °C on the outer surface of the first layer of the vacuum glazing, because the grey coating absorbs a large amount of solar energy. Similarly, when incident solar radiation passes through the vacuum gap, the temperature drops sharply, down to 28.2 °C on the inside surface.

Comparing these two cases, the difference for the outside surface temperature is 24.9 °C, while the difference for the inside surface temperature is only 3.3 °C. Therefore, the results indicate that the VIG retrofit can stabilize the fluctuation of the inside surface temperature under various climate conditions. Due to its excellent thermal insulation characteristics, the VIG retrofit application offers a scalable approach to achieving energy-efficient and thermally comfortable buildings in subtropical regions. Furthermore, an additional benefit is the resistance to condensation. Due to the humid environment in Hong Kong, conventional windows have a condensation problem in winter. However, for the VIG retrofit application, the inside vacuum glass surface temperature is close to the indoor air temperature, which is higher than the dew point temperature, so that the risk of condensation could be eliminated.

4.1. Case 1: VIG Retrofitting on Clear Glass

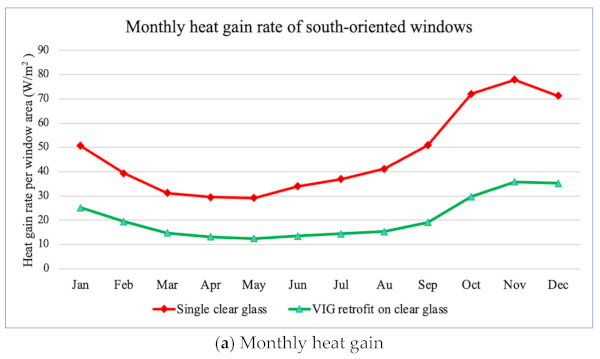

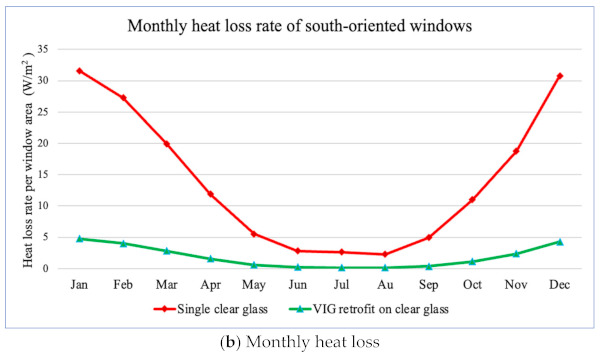

In Case 1, the VIG retrofit is applied to a single clear glass, which is a common fenestration product used in Hong Kong. Figure 12a shows the monthly heat gain rate of south-oriented windows. The largest heat gain rate appears in November, while the least appears in spring. This is because the heat gain rate is higher when there is more incident solar radiation on the windows in early winter. Compared with the single clear glass, the VIG retrofit can significantly reduce the total heat gain rate by 50.4% (January) to 62.7% (August). The average reduction ratio of the total heat gain from the glazing is 56.4%.

The monthly heat loss rates of the VIG retrofit application and the single clear glass in Hong Kong are presented in Figure 12b. Since Hong Kong is in a cooling load-dominated region, due to the excellent thermal insulation performance of the vacuum glazing, the heat loss through windows in winter is reduced dramatically compared with a single clear glass. The reduction in the heat loss is 85.0% in January to 94.2% in August. The average reduction ratio of the total heat loss is 89.0%. The heat loss in summer may happen at nighttime sometimes when no air-conditioning is provided.

The monthly heat gain and heat loss through the VIG retrofit are much less than those of the single-pane clear glass. In particular, the heat loss of the window can be minimized by applying the VIG retrofit. Therefore, the VIG retrofit can contribute to reducing the cooling load in summer and the heating load in winter of the building. Consequently, the energy consumption of the air-conditioning system can be significantly conserved.

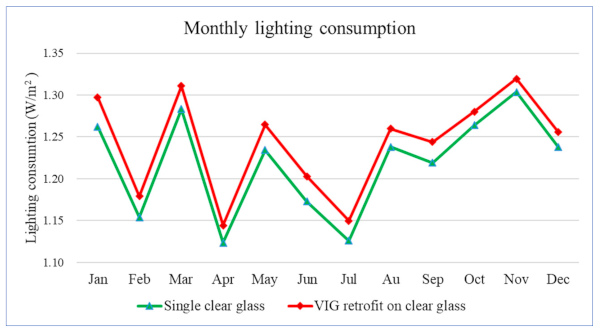

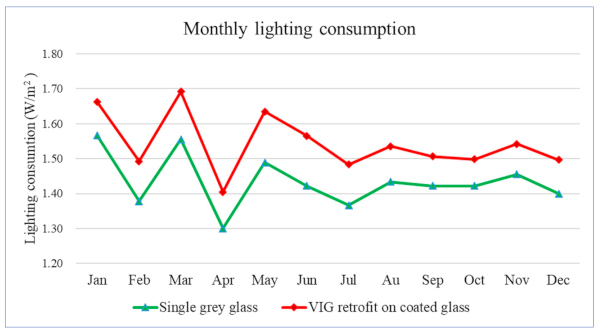

Based on the characteristics of the vacuum glazing with low-e coating, the VIG retrofit also affects the daylighting supply. As shown in Figure 13, the lighting energy consumption will be higher due to less solar radiation available in the rooms. The monthly lighting consumption of the VIG retrofit is 1.2–2.8% higher than that of the single-coated glass. The annual lighting energy consumption in the room with the single clear glass is 14.7 kWh/m2 (floor area), but the lighting consumption of the VIG retrofit room is only slightly higher, at 14.9 kWh/m2 (floor area).

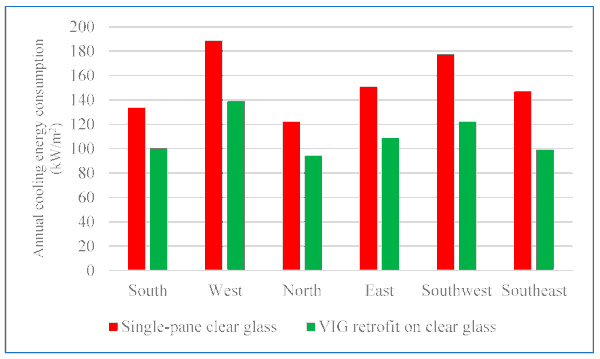

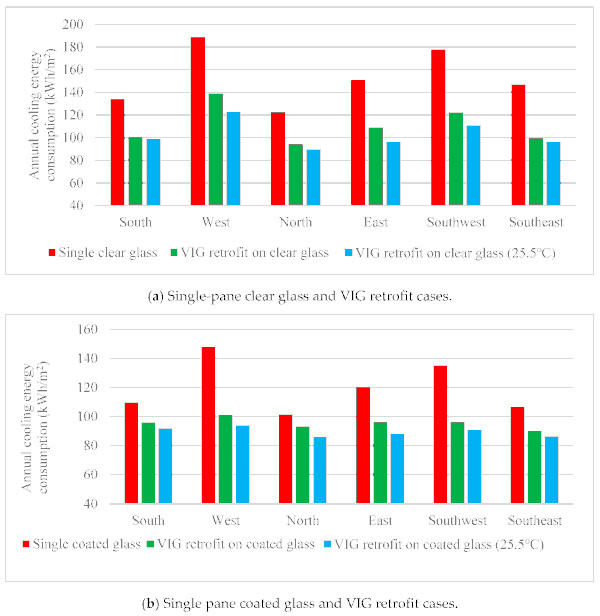

To investigate the annual thermal performance of the VIG retrofit application, Figure 14 shows the annual electricity consumption for air conditioning across different orientations of the model building. It is found that the single-pane clear glass leads to the largest annual cooling energy consumption among the other types. An office using the VIG retrofit has much better thermal performance for all orientations because the VIG retrofit has better heat insulation and solar heat control ability than typical single-glass windows. Consequently, the electricity consumption for cooling is reduced significantly for rooms with the VIG retrofit. For instance, a west-facing room with the VIG retrofit consumes about 139.0 kWh/m2 (floor area) for cooling per year, which is approximately 26.3% less than that of a corresponding room with single-pane clear glazing. For different orientations, the most cooling energy consumption decrease in the office rooms occurs on the west orientation, i.e., 49.6 kWh/m2 from 188.6 kWh/m2 to 139.0 kWh/m2 (floor area), followed by east, south, and north. The energy savings of the VIG retrofit are 27.8%, 25.2%, and 23.2% for east, south, and north orientations, respectively. Therefore, the VIG retrofit of the east and west facades exhibits better thermal performance due to more solar radiation exposure. The average energy-saving potential of the VIG retrofit for different orientations is 42.8 kWh/m2 (floor area). Overall, the VIG retrofit application demonstrates a significant energy-saving potential in Hong Kong.

4.2. Case 2: VIG Retrofit on Coated Glass

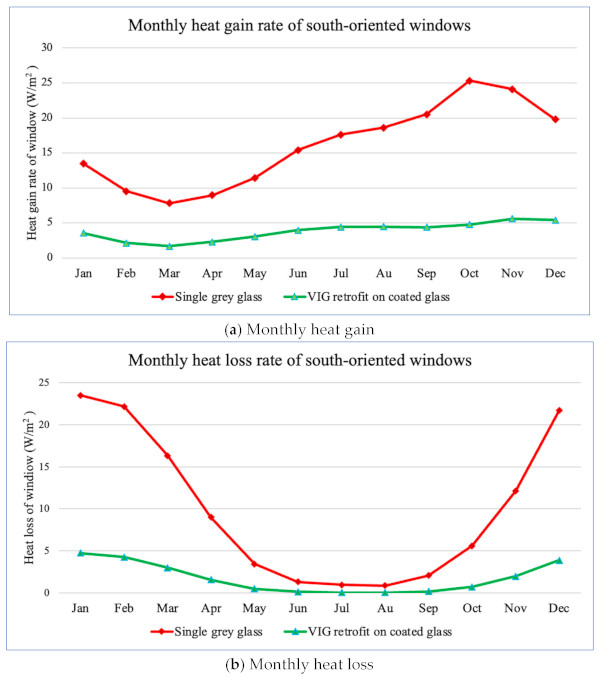

In Case 2, the VIG retrofit is applied to a single glass with a layer of grey coating so that the annual energy performance of the VIG retrofit application used in the field tests can be simulated. Compared with Case 1, similar trends in the monthly heat gain/loss rates of the two glazing systems can be observed in Figure 15. However, the monthly heat gain or heat loss through the single-pane coated glass is less than that through the single clear glass. It is because the grey coating has a lower SHGC and can reduce a certain amount of transmitted solar radiation. The experimental results indicate that the absorbed heat of the grey coating also increased the inside surface temperature of the window. On the other hand, the thermal insulation of the VIG retrofit contributes to stabilizing the inside surface temperature. In this case, the VIG retrofit can reduce the total heat gain rate by 72.6% (December) to 81.2% (October) compared with the single-pane coated glass. The reduction in the heat loss ranges from 79.8% in January to 94.3% in July. The average reduction ratios of the total heat gain and heat loss are 76.0% and 86.1%, respectively. Therefore, the VIG retrofit on the coated glass can also significantly reduce the indoor heat gain or heat loss, thereby reducing the air-conditioning energy consumption of the building.

Because of the grey coating, the daylight supply to the rooms is less than that of Case 1. Figure 16 shows the monthly lighting energy consumption of the single-coated glass and the VIG retrofit application. The annual lighting consumption of the single-coated glass is 17.0–17.7 kWh/m2 (floor area), which is 15.6–20.4% higher than that of the single clear glass. The monthly lighting energy consumption of the VIG retrofit is 5.3–10.1% higher than that of the single-coated glass. The annual lighting energy consumption of the VIG retrofit for this case is 18.2–20.0 kWh/m2 (floor area).

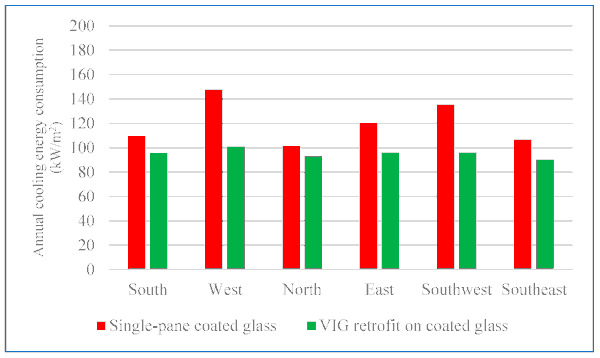

As shown in Figure 17, the east-facing room with VIG retrofit consumes about 96.0 kWh/m2 of cooling energy per year, which is approximately 24.1 kWh/m2 less than that of the corresponding room with single-pane coated glazing. The most cooling energy consumption of the office rooms occurs on the west orientation, followed by east, south, and north. The energy savings of the VIG retrofit application are 43.1 kWh/m2 and 13.7 kWh/m2 for rooms with windows on the west and south, respectively. The VIG retrofit application on the east and west facades has better energy-saving performance. However, when the corresponding rooms face north, the energy savings of the VIG retrofit are the lowest among other orientations. Therefore, it is not recommended to apply the VIG retrofit on north façades. The average energy-saving potential of the VIG retrofit for different orientations is 24.1 kWh/m2. Although the single-coated glass already shows an energy-saving potential of 17.1% (North) to 21.6% (West) compared with a single clear glass, the VIG retrofit application can further enhance the thermal insulation of the whole window system and reduce the annual energy consumption. Therefore, the VIG retrofit demonstrates a noticeable benefit in terms of energy and economic saving for applications in commercial buildings.

5. Thermal Comfort Analysis

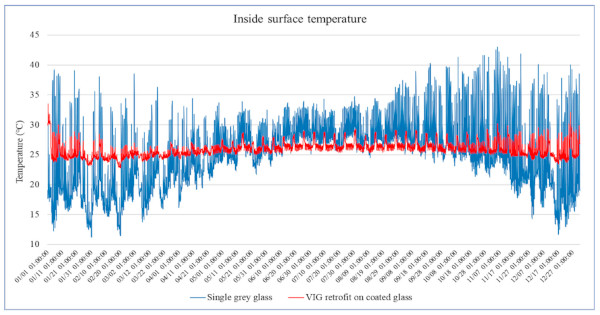

The previous results show that the VIG retrofit applications can effectively reduce the heat gain and heat loss. Figure 18 shows the inside surface temperature of the VIG retrofit on the single-coated glass (Case 2). Although the outdoor temperature fluctuates with different conditions, the inside surface temperature of the VIG retrofit is much more stable than that of the single-coated glass. The average inside surface temperature is around 25 °C. The standard deviation for the VIG retrofit application is 1.16, which is much lower than the standard deviation of the single-coated glass at 5.55. The results indicate that the VIG retrofit applications can stabilize the inner glass surface temperature. In terms of occupant preference in subtropical climates, it was found that a cooler indoor temperature is preferable [43]. The occupant behaviors were affected by their thermal sensation and the indoor operative temperature, such as the tendency to drink a cold beverage and wear more or thicker clothes [44]. Therefore, occupants may be more sensitive to dramatic temperature variations. The low-e coating of the vacuum glazing could control solar heat gain so that the radiant temperature of the room can also be decreased. Therefore, the indoor thermal comfort was expected to be improved when the VIG retrofit was applied.

5.1. Improvement on Thermal Comfort by the VIG Retrofit

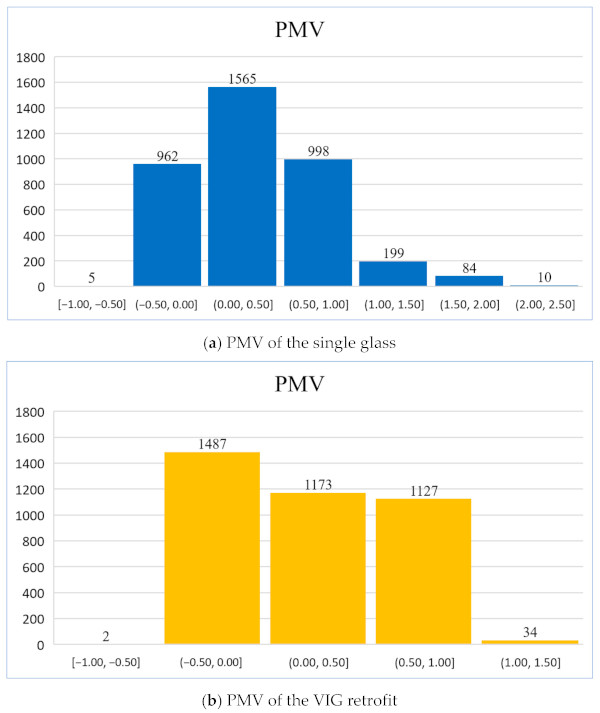

Figure 19 shows the annual distribution of the PMV for the VIG retrofit application and the single clear glass during occupancy time. It can be found that, compared with the single glass, the number of PMV of the VIG retrofit within ±0.5 and ±1 increased by 5.3% and 7.3%, respectively. Therefore, the thermal comfort can be improved by the VIG retrofit. It is worth noting that the cases of PMV > 1 are primarily prevented by the application of VIG retrofit, which indicates that the VIG retrofit can reduce the overheating situation.

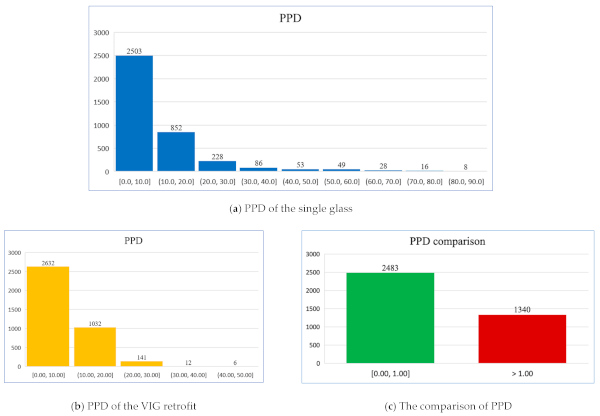

As shown in Figure 20a,b, for the VIG retrofit application, the PPD under 10 occurs for 2632 h, and the PPD under 20 for 3664 h, which is 5.2% and 9.2% higher than that of the baseline, respectively. It is also found that the cases of PPD > 30 rarely occur when the VIG retrofit is applied. Therefore, it can be concluded that the VIG retrofit application can effectively reduce the number of thermally dissatisfied people. As shown in Figure 20c, compared the PPD of the two types of windows at each time step, for most of the time, the prediction of thermal dissatisfaction of the VIG retrofit application is lower than that of the single clear glass. Therefore, the VIG retrofit can also significantly improve the thermal satisfaction of occupants.

5.2. Potential Energy Saving Due to Thermal Comfort Improvement

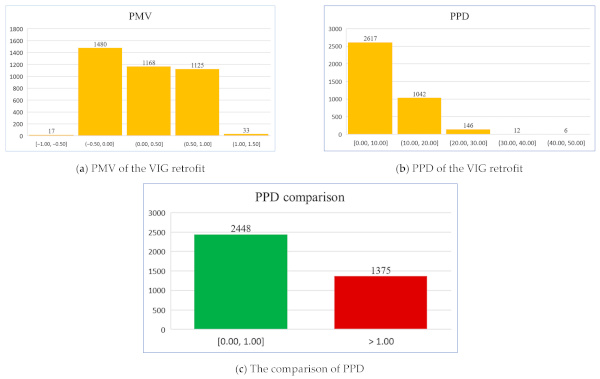

Due to the thermal performance improvement by the VIG retrofit, a higher cooling setpoint temperature for the indoor space is possible for additional energy savings without compromising the indoor thermal comfort. As shown in Figure 21, when the cooling setpoint is reset from 24.5 °C to 25.5 °C, the PMV and PPD for the VIG retrofit application demonstrate a similar distribution. Compared with the single glass, the number of PMV of the VIG retrofit within ±0.5 and ±1 increased by 4.8% and 7.4%, respectively. The PPD of the room with the VIG retrofit and 25.5 °C cooling setpoint in the range of 10 and 20 is 4.6% and 9.1% higher than that of the room with the single glass and 24.5 °C cooling setpoint. It can also be observed that the VIG retrofit application has a superior PPD compared with the baseline throughout the whole year, as shown in Figure 21c. Therefore, the improvement of thermal comfort and energy saving are guaranteed.

Based on the previous results, the additional energy-saving potential of the VIG retrofit due to the reset cooling point can be determined. Figure 22 shows the annual cooling consumption under different scenarios. For the VIG retrofit on clear glass, as presented in Figure 22a, the energy-saving potential is higher for the reset cooling setpoints, which are 26.1%, 32.0%, and 35.0% when facing south, west, and east, respectively. For the VIG retrofit on coated glass (Figure 22b), the average energy saving ratio also increases from 8.4–31.7% (setpoint: 24.5 °C) to 12.1–36.4% (setpoint: 25.5 °C). The average energy-saving potential is 45.2 kWh/m2 for the VIG retrofit on clear glass and 29.2 kWh/m2 (floor area) for the VIG retrofit on coated glass.

6. Economic Benefits and Payback Period

The cost of the proposed VIG retrofit system includes the cost of the vacuum glazing and the cost of installation and transportation. The total cost is between HK$1500 and HK$1800 per window area. An average cost of HK$1650/m2 is used in this study. Besides the initial investment, the maintenance costs of the vacuum glazing are negligible due to its long-term reliability.

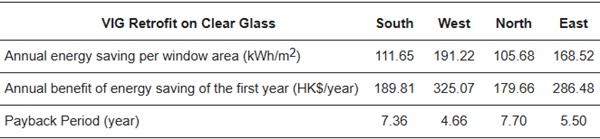

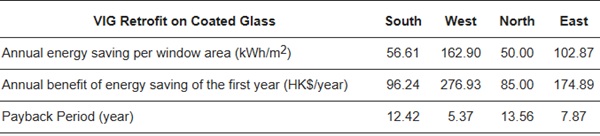

The benefit of annual energy savings refers to the electricity bill saved due to the energy consumption reduction. According to the electricity tariff of HK Electric, the total electricity bill includes the basic charge and the fuel clause charge. For a commercial building, the electricity price is about HK$1.75/kWh when the consumption exceeds 20,000 kWh per month. In this study, the electricity price is supposed to be HK$1.7/kWh. Based on the current price growth of natural gas and other fuels worldwide, an annual tariff increase rate of 8% is used in this study, which is also considered in the payback period calculation. Table 5 and Table 6 show the annual net benefits and payback periods of the VIG retrofit application under various scenarios. The VIG retrofit applications on the north-oriented façade have the least benefit and the longest payback period. Therefore, it is not recommended to apply the VIG retrofit on the north orientation of a building. In the other three directions, the average annual net benefit for the south, west, and east orientations is HK$267.1/m2 (window area) and HK$182.7/m2 (window area) for the VIG retrofit on clear glass and coated glass, respectively. The average payback period of the VIG retrofit on single clear glass is 5.8 years. For the VIG retrofit on single-coated glass, it has a longer payback period of 8.6 years on average.

Table 5. The annual energy saving benefit and payback period of the VIG retrofit on clear glass.

Table 6. The annual energy saving benefit and payback period of the VIG retrofit on coated glass.

The annual energy savings of the VIG retrofit application also lead to environmental benefits due to the reduction of carbon emissions. According to the estimation by HK Electric, the amount of carbon emissions is 0.66 kg CO2-e/kWh. The application of the VIG retrofit on clear glass can reduce up to 126.2 kg CO2-e/m2 per window area annually. For the application of the VIG on coated glass, the carbon emission reduction is up to 107.5 kg CO2-e/m2. Therefore, the VIG retrofit is also conducive to achieving the carbon neutrality goal by 2050.

7. Conclusions

The urgent need for building façade renovation was often hindered by certain technological and economic obstacles. To address these challenges, this paper proposes a novel retrofitting approach that integrates the vacuum glazing with excellent thermal insulation performance into the existing window system as secondary glazing. This cost-effective retrofitting solution was deployed in an existing high-rise office building in Hong Kong. A comprehensive analysis of field experimental data and simulation results is presented to compare the energy, lighting, and thermal comfort performance of the VIG retrofit application with other traditional glazing. The economic benefits and the payback periods were calculated for different VIG retrofit application scenarios.

The experimental results indicate that, for both sunny day and cloudy day cases, the VIG retrofit can effectively stabilize the inside surface temperature of the window glass. This phenomenon can also be observed by the simulated thermal response of the VIG retrofit under standard conditions. On average, the measured heat gain can be reduced by 85.3% and 80% on the sunny and cloudy days, respectively.

The energy simulation results indicate that the VIG retrofit can significantly reduce the total heat gain and heat loss. Therefore, the VIG retrofit application has a significant energy-saving potential in Hong Kong, especially when applied on the south, west, and east façades. For the case with the VIG retrofit on clear glass, the energy-saving potential is 25.2–27.1% of the total cooling energy consumption. For the scenario with the VIG retrofit on the coated glass in the building, the energy-saving potential ranges from 12.5–29.7%.

In terms of occupants’ thermal comfort, the VIG retrofit can significantly reduce the overheating situation and improve thermal satisfaction by 9.2%. It is found that the cooling setpoint could be reset for 1 °C higher without compromising the thermal satisfaction of occupants in general. If the thermostat setpoint is set as 25.5 °C, the average energy savings of the VIG retrofit on clear glass and coated glass are 45.2 kWh/m2 (floor area) and 29.2 kWh/m2 (floor area), respectively.

The annual energy savings would contribute to the economic benefit of the VIG retrofit applications. When adopting the VIG retrofit on clear glass, the average annual net benefit is HK$267.1/m2 (window area), and the average payback period is 5.8 years. The application of the VIG retrofit on coated glass presents an annual economic benefit of HK$182.7/m2 (window area) and a longer payback period of 8.6 years. From a cost-effective perspective, the priority orientation of the VIG retrofit on the existing façade is west, followed by east and south. It is not recommended to employ the VIG retrofit on north façades. Considering the declining price of vacuum glazing in the market in the future and the increasing price of energy globally, the VIG retrofit applications could provide greater economic benefits in the upcoming years. Furthermore, the VIG retrofit provides a noticeable environmental benefit, which can reduce the maximum carbon emission of 126.2 kg CO2-e/ m2 (window area) for the application on clear glass and 107.5 kg CO2-e/m2 (window area) for the application on coated glass.

This study demonstrates that the VIG retrofit application is a promising solution to achieving energy-efficient buildings and a comfortable indoor environment. Since thermal comfort can be significantly improved by the VIG retrofitting approach, the potential energy savings due to the higher indoor air temperature setpoint can be realized, and the risk of overheating can be reduced. Therefore, the VIG retrofit applications are not only beneficial for building owners and occupants but also contribute to achieving long-term climate resilience and the Climate Action Plan. The current findings are limited due to the specific weather conditions of this case study. The thermal comfort analysis could be enhanced with the consideration of occupant behavior in dynamic environments. In future work, the energy and thermal comfort performance of the VIG retrofit under different climatic conditions can be further investigated to reveal the energy-saving potential and applicability of this innovative retrofitting measure.